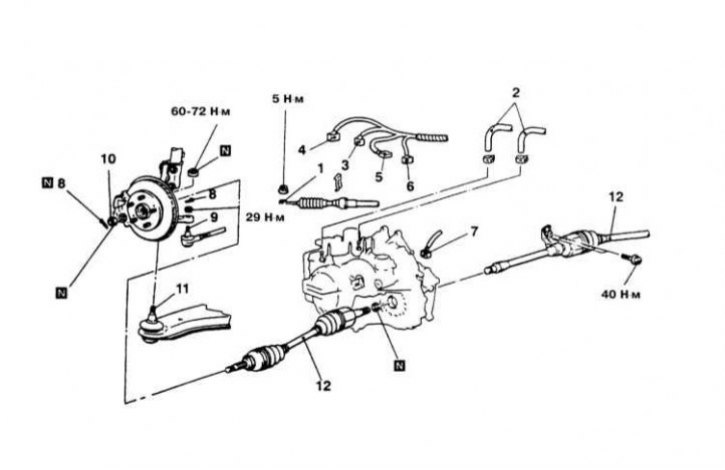

AT F4A51 installation details on Diamante models, left rear view (1 of 2)

1 - Place of connection of the AT shift control cable; 2 - Oil cooler hoses; 3 - Wiring connector for the start enable sensor-switch (PNP); 4 - Electrical wiring connector for the AT control solenoid valve; 5 - Electrical wiring connector of the input shaft speed sensor; 6 - Electrical wiring connector of the secondary shaft speed sensor; 7 - VSS wiring connector; 8 - Cotter pin; 9 - Tie rod end; 10 - Hub nut (drive shaft nut); 11 - Ball joint of the lower suspension arm; 12 - Drive shaft assemblies

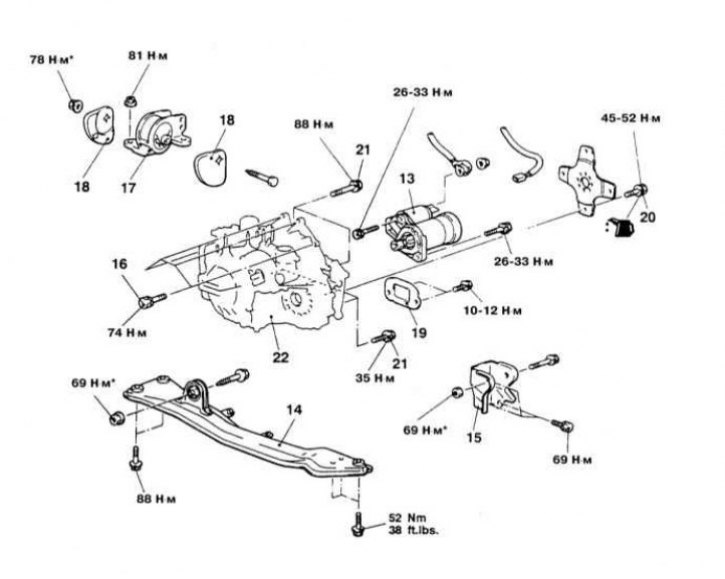

AT F4A51 installation details on Diamante models, left rear view (2 of 2)

13 - Starter; 14 - Central beam; 15 - Bracket for the rear jet stop of the suspension of the power unit; 16 - Bolt for fixing the upper section of the transmission; 17 - Bracket of the suspension support of the power unit; 18 - Support limiter; 19 - Transmission dome cover; 20 - Bolt for fastening the drive disk; 21 - Bolt for fixing the lower section of the transmission; 22 - Transmission assembly

Diamante Models

Note. The final tightening of the fasteners marked with an asterisk is carried out after lowering the power unit.

Removing

1. Details of AT assembly installation on Diamante models are shown in the illustrations.

2. Disable SRS (airbags) (see chapter Onboard electrical equipment).

3. Jack up the car and put it on stands.

4. Remove the front wheels.

5. Remove the side cover and crankcase protection.

6. Drain the ATF from the transmission case.

7. At a corresponding complete set of the car remove assembly of the forward catalytic converter.

8. Remove the exhaust pipe, main muffler and catalytic converter assembly.

9. Release from assembly of a rotary fist a tip of steering draft and a spherical support of the suspension arm.

10. Loosen the left drive shaft support bearing.

11. Using a pry bar, release the drive shafts from the transmission.

12. Remove the air cleaner assembly with the air intake sleeve connected to it.

13. Disunite a socket of a braid of an electroconducting of the engine.

14. On models with active suspension (Active-ECS) remove the compressor assembly from the transmission and tie it with wire - do not allow the compressor to hang on the air hose.

15. With the appropriate configuration, remove the support bracket for the jet stop of the suspension of the power unit.

16. Disconnect the speedometer drive cable from the transmission.

17. Release a fixing collar and disconnect a cable of a drive of a gear change from transmission.

18. Disconnect the oil cooler hoses from the transmission crankcase, - plug the open ends of the hoses immediately to prevent dirt from entering the system.

19. Disconnect the wiring from the start enable switch, kickdown servo switch, pulse generator, ATF temperature sensor, and transmission shift control solenoid valve.

20. Support the transmission with a jack and remove the support bracket for its suspension.

21. Turn out three top bolts of fastening of transmission to the engine.

22. On models with 4WS, remove the 4WS oil pump heat shield and remove the pump assembly - try not to stress the oil hoses.

23. On Active-ECS equipped models, disconnect the suspension height sensor rod from the lower control arm assembly.

24. Turn out a bolt of fastening of the oxygen gauge to the right beam.

25. Remove the starter assembly.

26. Remove the support brackets blocking access to the back cover of the transmission dome.

27. Remove the transmission dome/pan covers.

28. Turn out bolts of fastening of a floppy disk to the converter of rotation.

29. Turn out the bottom fixing bolts, separate transmission from the engine and take it from under the car.

Installation

1. Press the transmission against the engine, screw in the mounting bolts and tighten them with the required force (75 Nm)

2. Screw in the bolts securing the rotation converter to the drive disk and tighten them with the required force (46÷53 Nm).

3. Install the transmission dome/sump covers.

4. Install all powertrain suspension brackets that were removed to provide access to the rear cover of the transmission.

5. Reinstall the starter.

6. Screw in the bolt securing the oxygen sensor wiring harness to the right beam and tighten it with the required force (10÷12 Nm).

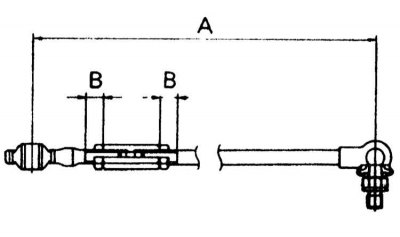

7. On models with Active-ECS, connect the suspension height sensor rod to the lower control arm. Adjust the stem length A, - the required value is 269÷270 mm.

8. If equipped, reinstall the 4WS pump and its heat shield. Tighten the pump and screen mounting bolts to the required torque (24 Nm).

9. Screw in three upper bolts of fastening of transmission to the engine. Tighten the bolts to the required torque (75 Nm).

One of the top bolts is also used to fasten the ground bar.

10. Install the transmission suspension support bracket. Tighten fasteners (bolts and nuts) supports with the required force (70 Nm).

11. Connect the wiring to the AT shift control solenoid valve, kickdown servo switch, pulse generator, ATF temperature sensor, and start enable switch (PNP).

12. Connect the oil cooler hoses to the transmission and secure them to their fittings with new clamps.

13. Connect to the transmission and secure the shift cable with a clamp.

14. Connect the speedometer drive cable to the transmission.

15. With the appropriate configuration, install the jet stop bracket for the suspension of the power unit and tighten the nut of its through bolt with a force of 50 ÷ 60 Nm. Tighten the two remaining bolts to 22 Nm.

16. On models with Active-ECS, reinstall the air compressor assembly and tighten its mounting bolts to the required torque (5 Nm).

17. Connect a contact socket of a braid of an electroconducting of the engine.

18. Install the air cleaner assembly with the air intake sleeve.

19. After replacing the circlips, fit the drive shafts into the transmission. Screw in the bolt of the left shaft support bearing and tighten it with the required force (45 Nm).

20. Place the tie rod end and ball joint of the lower suspension arm into the steering knuckle assembly. Tighten the castle nuts of the ball studs to the required torque (60÷72 Nm: support and 30 Nm: tip). Lock the nuts with new cotter pins.

21. After replacing the gaskets, reinstall the removed sections of the exhaust system.

22. Install the crankcase protection. Pour the correct amount of ATF of the required grade into the transmission (see chapter Settings and ongoing maintenance).

23. Start the engine and check it for signs of leak development.

Galant models through 1993 no.

Removing

1. On models equipped with speed control, remove the tempostat actuator assembly with its support bracket.

2. If equipped, disconnect the Active-ECS air compressor.

3. Drain the ATF from the transmission.

4. Remove the air cleaner assembly, integral cooler, and air duct sleeve.

5. Having previously marked, disconnect the electrical wiring from the solenoid valve, PNP sensor-switch, kickdown servo pulse generator and ATF temperature sensor.

6. Disconnect the speedometer drive cable and oil cooler lines from the transmission.

7. Having disconnected electroconducting, remove assemblage of a starter.

8. Turn out the top bolts of fastening of transmission to the engine.

9. Support the transmission with a jack, remove the support bracket for its suspension.

10. Jack up the car and put it on stands. Remove the crankcase protection elements.

11. Disconnect from assemblies of rotary fists steering drafts and lower suspension arms.

12. Release the drive shafts from the transmission housing (in order to avoid damage to the internal CV joints, do not pull the shafts, but pry them with a pry bar - try not to damage the oil seals). Tie the shafts with wire to the bottom elements.

13. On AWD models, disconnect the exhaust system and remove the transfer case.

14. Remove the bottom cover of the transmission dome and turn out the special bolts that secure the floppy disk to the rotation converter. In order to access each of the bolts in turn, turn the engine crankshaft at the pulley bolt using a socket wrench. Having unscrewed all the bolts, press the converter inside the transmission - if the converter remains on the engine, this will lead to oil entering its hub, which is fraught with failure of the assembly.

15. Turn out the lower fixing bolts, disconnect transmission from the engine and take it from under the car.

Installation

1. Having fixed the rotation converter in the transmission, press the assembly of the latter to the engine. Screw in the drive disc mounting bolts and tighten them to the required torque (46÷53 Nm). Screw in and tighten to 48 Nm the transmission mounting bolts. Install the dome cover.

2. On all-wheel drive models (AWD) install the transfer box assembly with frame elements. After replacing the gaskets, install the removed sections of the exhaust system.

3. After replacing the circlips, fit the internal driveshaft trunnions into the transmission.

4. Fill in rotary fists tips of steering drafts and spherical support of levers of a suspension bracket.

5. Install the transmission suspension support bracket.

6. Install the crankcase protection.

7. Install starter.

8. Connect the speedometer drive cable and oil cooler hoses to the transmission.

9. Connect wiring to solenoid valve, PNP switch, kickdown servo pulse generator, and ATF temperature sensor.

10. If equipped, reinstall the Active-ECS air compressor.

11. On models equipped with speed control, reinstall the tempostat actuator with support bracket.

12. Fill the transmission with the appropriate amount of ATF of the required grade (see chapter Settings and ongoing maintenance). On AWD models, check the fluid level in the transfer case.

13. Start the engine and let it idle for at least 2 minutes. Engage the parking brake and sequentially switch the selector lever to each of the provided positions, finally returning it to the position "N".

14. Check the ATF level, if necessary, make the appropriate adjustment.

Galant models since 1994

Removing

1. Disconnect the negative cable from the battery.

Attention! If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

2. Remove the air cleaner assembly with the air intake arms.

3. Drain the ATF from the transmission.

4. Give a nut of fastening of the lever of switching to transmission. Release the clamp and disconnect the drive cable from the transmission.

5. Remove the shift cable support bracket.

6. Having previously marked, disconnect the electrical wiring from the speedometer, solenoid valve, PNP sensor-switch, pulse generator, kickdown servo and ATF temperature sensor.

7. Mark and disconnect the oil cooler lines from the transmission.

8. Turn out a fixing bolt and remove from transmission measuring probe with a directing tube.

9. Remove and slide the starter assembly aside.

10. Support the engine with tool type MZ203827.

11. Remove the bracket for the rear jet stop of the suspension of the power unit.

12. Remove the transmission suspension support bracket.

13. Turn out the top bolts of fastening of transmission.

14. Jack up the car and put it on stands.

15. Remove the front wheels.

16. Remove the right crankcase protection section.

17. Remove the cotter pin and disconnect the tie rod end from the steering knuckle assembly.

18. Disconnect the anti-roll bar from the damper fork assembly.

19. Disconnect the damper fork from the transverse suspension control arm.

20. Release the ball bearings of the lower and compression arms and suspension from the steering knuckle.

21. Having prying with a mount, release the drive shafts from the transmission and tie them with wire to the elements of the bottom of the car.

22. Remove the cover from the transmission dome.

23. Turn out a through bolt of a forward jet stop of a suspension bracket of the power unit.

24. Remove the beam and the right triangular bracket.

25. Turn out bolts of fastening of a floppy disk to the converter of rotation and wring out the last in transmission.

26. Support the transmission with a trolley jack and remove the bottom pinch bolt.

Note. The pinch bolt is screwed into the transmission from the engine side and is located directly above the hole for the drive shaft.

27. Sliding back, separate the transmission from the engine and remove it from under the car.

Installation

1. Having fixed the rotation converter in the transmission, press the assembly of the latter to the engine. Screw in the transmission mounting bolts and tighten them to the required torque (48 Nm).

2. Screw in the bottom pinch bolt and tighten it with a force of 29÷34 Nm.

3. Connect the rotation transducer to the floppy disk, screw in the mounting bolts and tighten them to the required torque (45÷52 Nm).

4. Install the dome cover and tighten its fastening bolts to 9 Nm.

5. Install the beam and tighten the bolts of its fastening with the required force (88 Nm: front and 73 Nm: rear).

6. Install and loosely tighten the through bolt of the powertrain suspension front torque strut.

Note. The bolt is finally tightened to 57 Н·м after the engine is lowered.

7. Install the triangular bracket and tighten the bolts of its fastening with a force of 88 Nm.

8. After replacing the retaining rings, fill the internal pins of the drive shafts into the transmission - try not to damage the seals.

9. Fill in a rotary fist a tip of steering draft and spherical support of levers of a suspension bracket. Tighten castle nuts of hinges with the demanded effort (65 Nm: supports and 28 Nm: rod end).

10. Connect the damper fork to the lower suspension arm and tighten the through bolt of its fastening with a force of 88 Nm.

11. Connect the anti-roll bar to the fork and tighten the self-locking nut to 39 Nm.

12. Install the crankcase protection.

13. Install the wheels and carefully lower the vehicle to the ground.

14. Install the power unit suspension support bracket on the transmission and tighten the fixing nuts with a force of 43 Nm.

15. Install the rear jet mount bracket for the implement suspension.

16. Remove the engine support and tighten the transmission support through bolt to the required torque (69 Nm). Also finally tighten the front torque arm bolt.

17. Screw in the upper transmission mounting bolts and tighten them with the required force (48 Nm).

18. Install starter.

19. Install the dipstick with guide tube.

20. Install the shift cable support bracket.

21. Connect the shift lever and tighten its fastening nut with a force of 19 Nm.

22. Connect the oil cooler lines to the transmission and secure them to the fittings with new clamps.

23. Connect the wiring to the solenoid valve, PNP switch, pulse generator, kickdown servo and ATF temperature sensor.

24. Install the air cleaner assembly.

25. Connect the negative cable to the battery.

26. Make sure that the car is installed horizontally and fill the transmission with the required amount of ATF of the required grade (see chapter Settings and ongoing maintenance).

27. Start the engine and let it idle for at least 2 minutes. Engage the parking brake and sequentially switch the selector lever to each of the provided positions, finally returning it to the position "N".

28. Check the level of ATF, if necessary, make the appropriate adjustment.

29. Check up serviceability of functioning АТ. Make sure that the engine can only be started in the positions "R" And "N" selector lever.

Mirage Models

Removing

1. Disconnect the negative cable from the battery.

Attention! If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

2. Remove the battery from its tray.

3. Remove the air cleaner assembly with the air intake sleeve.

4. Jack up the car and put it on stands.

5. Remove the crankcase protection.

6. Drain ATF from their transmissions.

7. On 1.6L models, remove the tension rod.

8. Disconnect the control cable and oil cooler hoses from the transmission.

9. On models equipped with a 4-speed transmission, disconnect the throttle cable.

10. On 4-speed transmission models, disconnect the wiring from the shift control solenoid, PNP switch, kickdown servo switch, pulse generator, and ATF temperature sensor.

11. Disconnect the speedometer drive cable and remove the starter.

12. Turn out fixing bolts and remove an arm of a support of a suspension bracket of transmission.

13. Disconnect the anti-roll bar from the lower suspension arm.

14. Release from a rotary fist hinges of a tip of steering draft and spherical support of the suspension arm.

15. Release the drive shafts from the transmission and tie them to the elements of the vehicle bottom.

16. Support the engine and remove the central beam.

17. Remove the cover of the dome of the transmission and turn out the bolts of the drive disk.

18. Turn out the bottom coupling bolt located directly over a hole under installation of a power shaft.

19. Support the transmission with a trolley jack, then move it to the right, separating it from the engine, and remove it from under the car.

Installation

1. Having fixed the rotation converter in the transmission, press the assembly of the latter to the engine. Screw in the transmission mounting bolts and tighten them to the required torque (43÷55 Nm: for models up to 1992 vol. and 48 Nm: for models since 1993 vol.).

2. Tighten the drive disc mounting bolts to 46÷53 Nm, then install the transmission dome cover.

3. Install the center beam.

4. After replacing the retaining rings, fill the internal pins of the drive shafts into the transmission - try not to damage the seals.

5. Fill the steering knuckles with the tie rod ends, the ball joints of the suspension arms and the anti-roll bar struts.

6. Install the transmission hanger bracket.

7. Install starter.

8. Connect the speedometer drive cable.

9. Connect the wiring to the solenoid valve, PNP switch, pulse generator, kickdown servo and ATF temperature sensor.

10. Connect control cables and oil cooler lines to transmission.

11. On 1.6L models, install the tension rod.

12. Install the air cleaner assembly.

13. Install the battery with tray.

14. Connect battery wiring (positive wire first, then negative).

15. Make sure the vehicle is level and fill the transmission with the required amount of ATF of the required grade (see chapter Settings and ongoing maintenance).

16. Start the engine and let it idle for at least 2 minutes. Engage the parking brake and sequentially switch the selector lever to each of the provided positions, finally returning it to the position "N".

17. Check the ATF level, if necessary, make the appropriate adjustment.

18. Check up serviceability of functioning АТ. Make sure that the engine can only be started in the positions "R" And "N" selector lever.