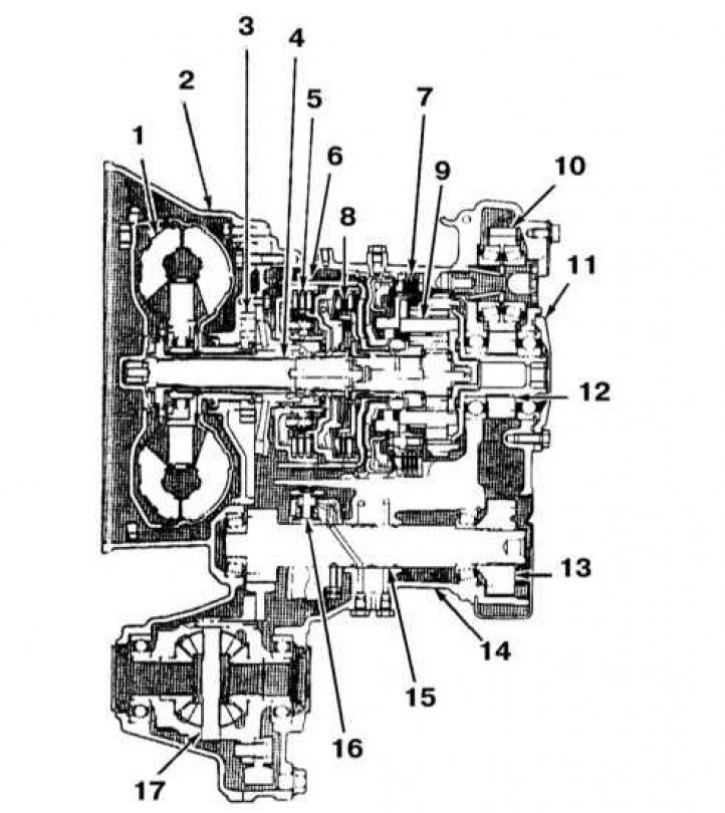

Design АТ F3А21

1 - Rotation converter; 2 - Carter (dome) converter; 3 - Oil pump; 4 - Primary shaft; 5 - Front clutch; 6 - Brake for enabling the kickdown mode; 7 - Brake for low gears and reverse; 8 - Rear clutch; 9 - Planetary assembly; 10 - Intermediate gear of the distributing assembly; 11 - Back cover; 12 - Drive gear of the distributing assembly; 13 - Driven gear of the distributing assembly; 14 - Transmission housing; 15 - Shaft of distributing assembly; 16 - Control regulator; 17 - Differential

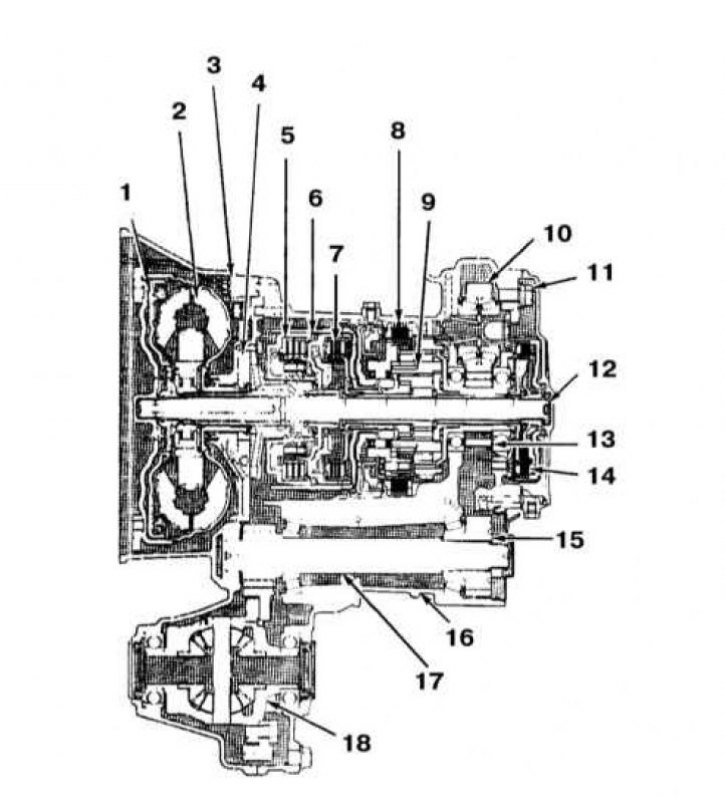

Design AT series F4A20 (F4A22 and F4A23)

1 - Clutch of rotation converter; 2 - Rotation converter; 3 - Carter (dome) converter; 4 - Oil pump; 5 - Front clutch; 6 - Brake for enabling the kickdown mode; 7 - Rear clutch; 8 - Brake for low gears and reverse; 9 - Planetary assembly; 10 - Intermediate gear of the distributing assembly; 11 - Back cover; 12 - Primary shaft; 13 - Drive gear of the distributing assembly; 14 - End clutch; 15 - Driven gear of the distributing assembly; 16 - Transmission housing; 17 - Shaft of distributing assembly; 18 - Differential

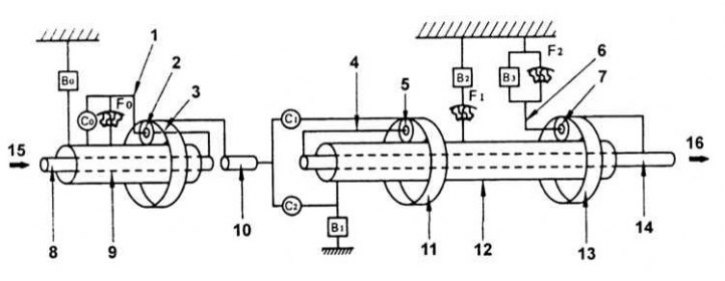

Scheme of the functioning of the planetary gearbox

1 - Carrier of the increasing planetary gear set; 2 - Satellite of the increasing planetary gear set; 3 - Epicycle of the increasing planetary series; 4 - Carrier of the front planetary gear set; 5 - Satellite of the front planetary gear; 6 - Carrier of the rear planetary gear set; 7 - Satellite of the rear planetary gear; 8 - Input shaft of the increasing planetary gear set; 9 - Sun gear of the increasing planetary gear set; 10 - Input shaft; 11 - Epicycle of the front planetary gear; 12 - Sun gears of the front and rear planetary gear sets; 13 - Epicycle of the rear planetary gear; 14 - Output shaft

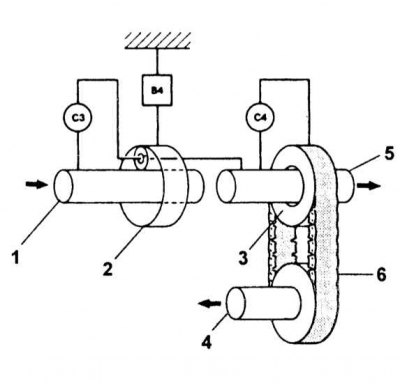

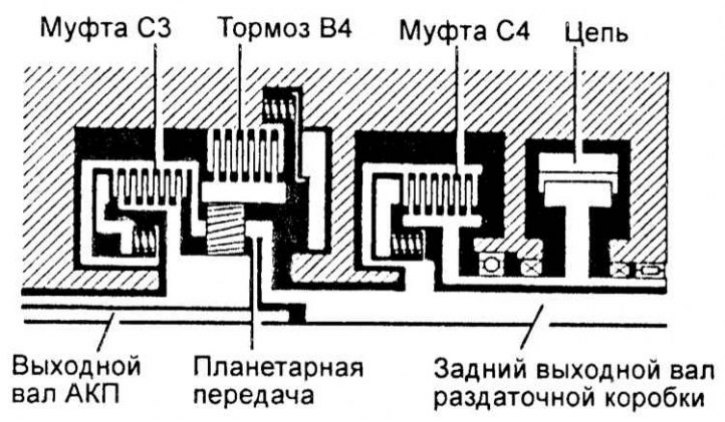

Scheme of functioning of the planetary transfer case

1 - Gearbox output shaft; 2 - Epicycle; 3 - Leading sprocket; 4 - Front wheel drive shaft; 5 - Rear wheel drive shaft; 6 - Drive chain

To complete the models considered in this manual, 4-speed AT series F3A20 are used (F3A21) and F4A20 (F4A22, F4A23, F4A33 and F4A51). All transmissions are equipped with a locking rotation converter. The converter provides direct coupling between the engine and driving wheels of the car. Transmissions can be electronically controlled - in this case, the onboard processor switches the box up or down based on the analysis of information from three electromagnetic blocks mounted on the valve body.

Due to the complexity of the AT design, the lack of free sale of replaceable internal components, and the need to use special equipment, the compilers of this Guide do not recommend car owners to overhaul the transmission on their own. In this Chapter, only the procedures for diagnosing general AT failures, its current maintenance, basic adjustments, removal and installation are considered.

Sometimes, in the event of a serious breakdown, it is wiser and easier to replace the transmission than to spend time and money on rebuilding a failed assembly. Regardless of the chosen method of introducing a failed AT into operation, the independent implementation of its removal and installation will help to significantly reduce costs (first make sure that the transmission really needs refurbishment).

Attention! Towing a car with a failed AT must be carried out at a speed not exceeding 50 km / h (30 mph) and at a distance of no more than 80 km (50 miles)!

Design and principle of operation

In the general case, an automatic transmission consists of a rotation converter, a transfer case and a differential. The F3A21 transmission is a 3-speed AT with mechanical control. The F4A20 series features a 4-stage design and is electronically controlled.

The internal structure of the transmissions of both series is almost the same. The main difference is the use of overdrive 4th gear on F4A20 series assemblies. The transmission consists of a 3-element rotation converter with a control regulator (F3A20 series), clutch converter (F4A20 series), one planetary assembly, one brake band and three (F3A20 series) or four (F4A20 series) multi-plate clutches.

The planetary gear assembly consists of two planetary gear sets. The transfer case includes a planetary gear set with friction controls (lockup clutch and brake). The operation of the entire transmission is controlled by an electronic unit. Switching of high-speed modes is made by means of the selector lever established in inside of the car. The selector is connected to the valve assembly by means of a cable, and with its help it is possible to set the range of gears used. In addition to the selector in the cabin, one or more switches are provided to set special modes of operation of the transmission.

To prevent breakdowns of the AT when the speed range is incorrectly selected, for example, moving from "D" V "R" there is a lock on the selector lever, "dangerous" switching can only be carried out when the lock button is pressed. The use of a latch allows you to avoid a situation where, through negligence, one of the ranges of motion can be turned on and the car starts to move uncontrollably. The selector lever can be set to one of six fixed positions: "R", "R", "D", "N", "2" And "L", the purpose of each of which is discussed below.

Position "R"

Selected when parking the car. In this position, all controls are turned off in the transmission, and its output shaft is blocked, it is impossible to move the car. Move selector to position "R" only after the vehicle has come to a complete stop.

Attention! Translation of the selector into position "R" while driving can lead to transmission failure!

Position "R"

Reverse. Move selector to position "R" possible only after the vehicle has come to a complete stop.

Attention! Engaging reverse gear while the vehicle is moving can damage the transmission!

Position "N"

Neutral position. In the box, all controls are turned off, which ensures the absence of a rigid kinematic connection between its drive and driven shafts. In this case, the output shaft blocking mechanism is disabled, i.e. the car can move freely. It is not recommended to shift the transmission to the position "N" when coasting.

Attention! Never turn off the ignition when driving downhill!

Position "D"

Basic driving mode. Provides automatic shifting from first to fourth gear. Recommended for driving under normal conditions.

Position "3"

Driving is allowed in the first three gears. It is recommended to use when driving on a hilly road or in conditions of frequent stops (busy urban cycle).

Position "2"

14 Driving is allowed only in first and second gears. Recommended for use, for example, on winding mountain roads. Switching to third and fourth gears is prohibited. In this range, the engine braking mode is effectively used.

Position "L"

Driving is allowed only in first gear. This range allows maximum implementation of the engine braking mode. It is recommended when driving on steep descents, climbs and off-road.

Mode "OD" (F4A20 series transmissions)

Permission to use the fourth, overdrive, gear is carried out using a special button "OD". If the button is in the recessed state and the lever is set to the position "D", then upshifting is allowed. Otherwise, the inclusion of the fourth (boosting) transmission is prohibited. The state of the control system in this case is determined by the control lamp "O/D OFF". If overdrive is enabled, the indicator is off; if overdrive is disabled, it is on. The mode is used when driving at a constant speed on straight sections of the motorway. Avoid using the OD mode in urban areas, especially in winter when engine braking becomes vital. Also, do not turn on the overdrive mode when the car is fully loaded.

Special programs (if provided)

On vehicles with AT, there are two modes of gear shift control: "economical" (NORMAL) And "sports" (POWER). The choice is made by means of a special switch mounted in the center console of the car.

Economy mode (NORMAL)

In this mode, there is a minimum fuel consumption. Gear shifts occur in the middle of the corresponding engine ranges, the character of the car's movement is calm, smooth.

Sports mode (POWER)

When this mode is enabled, the control lamp lights up on the panel of priors "ECT POWER". In this mode, the maximum engine power is taken off - the box is switched at the upper limit of the corresponding engine speed ranges. The acceleration of the car is greatly increased, fuel consumption, respectively, increases.

Planetary gearbox

The planetary gearbox consists of three planetary gear sets, three lockup clutches, four brakes and three freewheels.

Power from the engine through the torque converter is transmitted to the input shaft of the planetary gearbox.

Gear shifting is accomplished by applying a specific combination of brakes and freewheels, which changes the speed of the output shaft.

Elements of the planetary gearbox

A functional diagram of the planetary assembly of an automatic transmission is shown in the illustration.

Clutch for step-up planetary gear set (C0) connects both the sun carrier and the sun wheel of the step-up planetary gear set.

Brake of step-up planetary gear set (B0) stops the sun wheel of the boost planetary gear set.

Clutch No. 1 freewheel (F1) when the second gear brake is applied, it inhibits counterclockwise rotation of the sun gears of the front and rear planetary gear sets.

Forward clutch (C1) connects the input shaft and the epicycle of the front planetary gear set.

2nd gear brake (AT 2) stops the #1 freewheel outer race, preventing the front and rear sun gears from turning counterclockwise.

1st gear and reverse brake (AT 3) stops the rear planet carrier.

Freewheel No. 2 (F2) prohibits the rotation of the carrier of the rear planetary gear set counterclockwise.

Direct clutch (C2) connects the input shaft and the sun gears of the front and rear planetary gear sets.

Brake providing engine braking mode in second gear (IN 1) stops the rotation of the sun gears of the front and rear planetary gear sets.

Freewheel clutch for step-up planetary gear set (F0) when starting the engine, it connects the sun gear and the carrier of the boost planetary gear set.

Planetary transfer case

The operation diagram of the planetary transfer case is shown in the illustration.

The transfer box contains one planetary gear set, two lock-up clutches and one brake.

Elements of the planetary transfer gearbox:

- Forward clutch (C3) connects the output shaft of the gearbox to the pinion gear of the planetary gear of the transfer case.

- Direct clutch (C4) connects the rear wheel drive shaft and the front wheel drive chain drive sprocket.

- overdrive clutch (AT 4) stops the rotation of the epicycle of the planetary gear set of the transfer case.

The device of the hydraulic part of the control system

Transmission

The hydraulic part of the control system consists of an oil pump, valve assembly, solenoid valves, clutches and brakes, as well as channels connecting the listed elements. The fluid pressure generated by the pump is used to control the friction elements of the transmission, feed the torque converter and lubricate. The valve assembly contains three switching solenoid valves. With their help, the electronic unit controls the gear shift and torque converter lockup.

Transfer case

The hydraulic part of the transfer box control system includes: valve box, solenoid valve No. 4, brake (AT 4), two locking clutches (NW, C4), as well as channels connecting the listed elements. The purpose of the box is to control the planetary series, which can be carried out either manually or automatically by an electronic unit.

Electrical part of the control system (F4A20 series transmissions)

The electrical part controls gear shifting in the gearbox and transfer case, as well as the torque converter lock-up clutch. It consists of three parts: vehicle speed sensors (VSS),throttle position sensor (TPS) and other information sensors that monitor the parameters of the state of the transmission and transmit data to the electronic control unit; an electronic control unit, which, based on the analysis of the data coming to it, determines the switching points in the gearbox and transfer case, and also controls the torque converter lock-up clutch; and the executive part, consisting of four solenoid valves.