- a) Reduced engine recoil efficiency;

- b) Violation of regulations;

- c) Hydraulics malfunction;

- d) Mechanical damage;

- e) Failures of the onboard processor / its signal circuit.

Failure diagnosis should always start with the simplest checks: check the level and condition of the ATF (see chapter Settings and ongoing maintenance), check the adjustment of the gearshift and throttle actuators. Next, test drive the vehicle to determine the effectiveness of the corrections made. If the problem cannot be fixed, you should drive the car to a service station for more detailed diagnostics using special equipment. A description of some of the symptoms of AT malfunctions is given in the Section on the diagnosis of failures of vehicle components and systems at the beginning of this Guide.

List of the most typical AT failures

Note. See also the relevant subsection in the Section on the diagnosis of failures of vehicle components and systems in the Introduction to this Guide.

The transmission moves the car forward or backward

- The adjustment of the shift rods is broken;

- Low ATF level/low hydraulic pressure as a result of oil filter blockage, incorrect valve assembly installation, or damage to the pressure reducing valve/control valve of the rotation converter.

Movement is missing in the provisions "D" And "2"

- Faulty front clutch.

Forward gears not working

- Faulty rear clutch;

- Faulty accumulator valve "N-D".

Engine stalls when shifting transmission from position "N" into position "D" or "R"

- The engine does not develop the required power;

- AT valve assembly incorrectly installed;

- Stuck control ball valve assembly;

- Defective rotation converter clutch valve or accumulator valve "N-D".

Gearbox slips when moving forward

- Dropped ATF level/hydraulic pressure;

- Faulty one-way clutch;

- Faulty valve assembly;

- Excessively worn rear clutch.

Box slips when reverse is turned on

- Dropped ATF level/hydraulic pressure;

- Faulty low gear/reverse brake circuit;

- Excessively worn front clutch;

- Faulty valve assembly.

Vehicle reception is too weak when driving in 2nd and 3rd gears

- Dropped ATF level/hydraulic pressure;

- Rotation transducer defective;

- Faulty rear clutch;

- Faulty/incorrectly installed valve assembly;

- Faulty brake assembly for enabling the kickdown mode;

- The kickdown servo setting is broken.

Reduced efficiency of engine braking in the mode "L"

- Faulty valve assembly;

- The brake assembly of low gears / reverse modes is faulty.

Rotary converter stop speed too low

- Insufficient power developed by the engine;

- Rotation transducer defective.

Rotary converter stop speed too high

- Dropped ATF level/hydraulic pressure;

- Faulty one-way clutch;

- Faulty front clutch;

- Faulty rear clutch;

- Faulty valve assembly.

The vehicle is moving with the position "N" transmission

- Faulty front or rear clutch.

Transmission won't shift to park

- The adjustment of the switching drive is broken;

- Defective position switching mechanism "R".

There is a discrepancy between the selected and actually activated modes

- Dropped ATF level/hydraulic pressure;

- Faulty valve assembly;

- Faulty front clutch;

- The brake band of inclusion of the kickdown mode is faulty;

- The adjustment of the kickdown mode servo is broken;

- The control regulator is defective.

Transmission does not downshift in any of the positions

- The serviceability of the throttle valve is broken;

- Faulty 1/2 shift valve;

- The valve of switching of 2/3 transfers is faulty;

- The control regulator is defective.

The serviceability of switching transmission from 1st gear to 2nd is broken

- Dropped ATF level/hydraulic pressure;

- The patency of the oil filter is broken;

- Faulty kickdown brake band;

- The adjustment of the kickdown mode servo is broken;

- Faulty front clutch;

- The control regulator is faulty;

- Faulty valve assembly.

The serviceability of switching transmission from 2nd gear to 3rd is broken

- Dropped ATF level/hydraulic pressure;

- The patency of the oil filter is broken;

- Faulty kickdown brake band;

- The adjustment of the kickdown mode servo is broken;

- Faulty front clutch;

- The control regulator is faulty;

- Faulty valve assembly.

Shifting from 1st to 2nd and from 2nd to 3rd is too abrupt

- Broken throttle cable adjustment;

- Faulty valve assembly;

- The control regulator is faulty;

- Faulty front clutch;

- Faulty kickdown brake band;

- The kickdown servo setting is broken.

Shifting from 3rd to 2nd and from 2nd to 1st is too abrupt

- Faulty kickdown brake band;

- The adjustment of the kickdown mode servo is broken;

- The control regulator is faulty;

- Faulty valve assembly.

Rotary transducer makes a howling sound during operation

- Oil pump defective.

Rotary converter rattles during operation

- Cracked drive disk;

- The bolt securing the rotation transducer to the drive disk is loose.

Primary Checks

1. During a short drive, warm up the transmission to normal operating temperature.

2. Check the ATF level (see chapter Settings and ongoing maintenance):

- a) If the liquid is clearly not enough, make the appropriate adjustment by adding the required amount of fresh ATF. Verify that the dipstick adjustment is correct, then check the transmission for signs of external leaks;

- b) If the level is excessively high, drain excess ATF, then check it for signs of coolant presence, indicating a leak in the internal radiator bulkheads separating its heat exchanger from the side ATF tanks;

- c) If the ATF is foamy, empty the transmission and refill it with fresh fluid - check the drained ATF for signs of coolant presence.

3. Check engine idle speed setting (see chapter Power and exhaust systems). If necessary, drive the car to a workshop to make the appropriate adjustments.

Note. If the engine is out of order, you should not proceed with the initial checks of the transmission until the appropriate corrections have been made.

4. Make sure that the traction control link/cable is properly adjusted and runs smoothly.

Diagnosis of ATF leaks

Most leaks are easily identified by visual inspection. Repair usually consists of replacing the corresponding defective oil seal or gasket. If the external inspection fails to identify the source of the leak, proceed as described below.

First of all, it is necessary to exclude the possibility of error in determining the nature of the leak. ATF should not be confused with engine oil or brake fluid (transmission fluid is usually dark red in color).

Run a short test to find the source of the leak (several kilometers) ride, then park the car over a blank sheet of cardboard. After a couple of minutes, the source of the leak can be identified by traces of liquid dripping onto the cardboard.

Carefully inspect the suspected area and the surrounding surface, paying special attention to the joints of the mating gasket surfaces. In order to expand the viewing angle, use a pocket mirror.

If you still cannot find the source of the leak, carefully wipe the surface of the suspected area with a rag soaked in solvent, then dry it.

Make another short drive, this time changing your speed frequently, then re-examine the cleared suspect area.

After identifying the source of the leak, it is necessary to determine and eliminate the cause of its development, and only then proceed to perform the necessary restoration work. Replacing a damaged gasket will not lead to the desired result if the defect in the mating surface that led to the failure of the seal is left unrepaired. So, the deformed flange must be straightened.

The following subsections list the most common causes of ATF leaks and the conditions that must be met to prevent recurrence.

Note. Some of the listed requirements cannot be met without the use of special equipment. In this case, the car should be driven to a service station.

Leakage through gasket surfaces

1. Periodically inspect the transmission oil pan. Check that the fixing bolts are in place and securely tightened, make sure that there are no signs of mechanical damage on the cover (deformation of the sump can lead to failure of the valve assembly located inside the transmission).

2. Possible reasons for the development of leaks through the sump include excessively tight tightening of the mounting bolts, violation of the patency of the ventilation line, mechanical damage to the sealing surface of the transmission case, destruction of the gasket, as well as the occurrence of cracks or porosity of the walls of the case. If the gasket of the pan or transmission case is formed by a sealant pad, the possibility of an incorrect choice of the type of the latter cannot be ruled out. Pan gasket leaks can also be caused by overfilling the crankcase with transmission fluid or by increasing ATF pressure.

Leaks through glands and cuffs

1. The most typical causes of failure of transmission oil seals include excessively high ATF level / pressure, violation of the patency of the ventilation pipe, mechanical damage to the walls of the seat, damage to the oil seal itself, or improper installation of the latter. It is also possible that the trunnion of the shaft threaded into the stuffing box is damaged, or the latter has excessive play as a result of bearing wear.

2. Check the condition and correct fit of the dipstick guide tube seal. Periodically inspect the surface around the speedometer/speedometer drive gear for signs of leaks (VSS). If necessary, replace the sealing ring.

Leaks through defects in the walls of the transmission case

1. The reason for the development of ATF leaks may be the formation of cracks or pores in the body of the transmission housing - consult a car service specialist.

2. Check up tightness of union knots of connection of hoses of an ATF cooler.

Leaks through the breather and filler neck

Breather or filler leaks can be caused by an overfilled transmission, coolant in the ATF, a blocked breather/vent or return drains.

Check of serviceability of functioning of mechanical subsystems AT

Fully braked test (stall test)

1. The performance of the transmission and engine is made by measuring the speed of the crankshaft in the positions "R" And "D" AT with a fully braked car.

Attention! ATF must be warmed up to normal operating temperature (50÷80°С). The duration of each check should not exceed five seconds. The check should be carried out by two people: one must observe the wheels of the car, the second performs the necessary manipulations in the car.

2. Brake the front and rear wheels of the vehicle.

3. Connect a tachometer to the engine.

4. Fully apply the parking brake.

5. With your left foot, depress the foot brake pedal as far as it will go.

6. Move the transfer case control lever to position H2.

7. Start the engine. Move the AT selector lever to position "D", fully depress the gas pedal and quickly read the tachometer readings.

Attention! If, during the test, the rear wheels of the vehicle begin to rotate before the engine speed reaches the required value (2300÷2600 rpm), release the gas pedal and stop testing.

8. Carry out a similar check with the transmission in position "R".

9. If the engine speed in both cases turns out to be the same and lower than required, therefore, the engine does not develop full power, or the AT torque converter freewheel is faulty.

Note. If the frequency is lower than required by 600 rpm, the torque converter itself may be faulty.

10. If the engine speed is higher than required in the transmission position "D", this may indicate an excessive decrease in pressure in the main line, slipping in the freewheel No. 2, a malfunction of the freewheel of the increasing planetary gear set, or slipping in the direct clutch of the transfer case.

11. Exceeding the engine speed in position "R" transmission indicates a pressure drop in the main line, slip in the direct clutch, slip in the brake of the first and reverse gears, malfunction of the freewheel of the boosting planetary gear set, or slip in the direct clutch of the transfer case.

12. If the engine speed is too high in both transmission positions, it means that either the pressure in the main line has dropped excessively, or the ATF level does not correspond to the required value, or the freewheel clutch of the boosting planetary gear set is malfunctioning, or there is a slip in the transfer box direct transmission clutch.

Checking the switching delay time

1. If the selector lever is moved to one of the forward ranges while the engine is idling, some time should elapse before the start of movement. By the duration of this delay, one can judge the proper functioning of the interlocking clutches of the increasing planetary gear set, forward gear, direct gear and the first and reverse gear brakes.

Attention! The check should be made with the engine warmed up to normal operating temperature. The final result should be obtained by averaging the results of three tests, between each of which there should be at least one minute. Below is a detailed description of the progress of this check.

2. Fully apply the parking brake. Move the transfer case control lever to position H2.

3. Start the engine and check its idle speed, - if necessary, make the appropriate adjustment.

4. Move the selector lever from the position "N" into position "D" and use a stopwatch to measure the delay time - the average value of three consecutive measurements should not exceed 1.2 seconds.

5. Proceeding in a similar manner, determine the delay time for engaging the reverse gear, which should not exceed 1.5 seconds.

6. Excessive turn-on delay may be caused by too low main line pressure, malfunction of the forward clutch, freewheel of the planetary booster assembly, or first and reverse brakes.

Hydraulic checks

Note. An assistant will be required to perform the checks described below.

1. Check ATF level and condition (see chapter Settings and ongoing maintenance).

2. During a short drive, warm up the transmission to normal operating temperature.

3. Jack up the vehicle and place it on jack stands so that the drive wheels are completely off the ground.

4. Following the instrument manufacturers' instructions, connect a tachometer. Position the tachometer so that its indicator is clearly visible from the driver's seat.

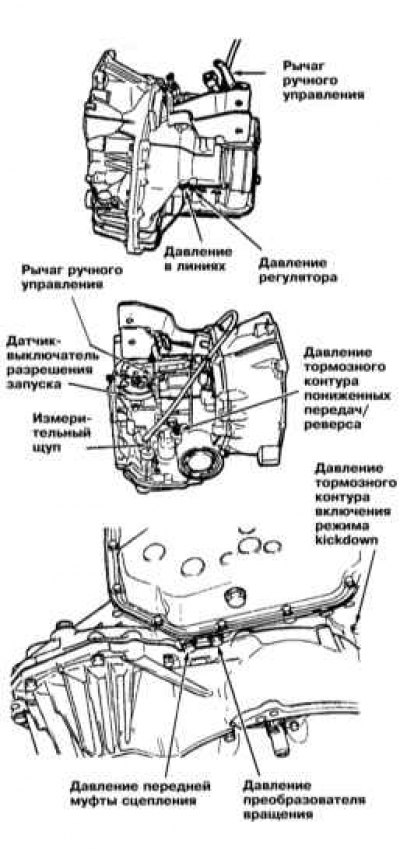

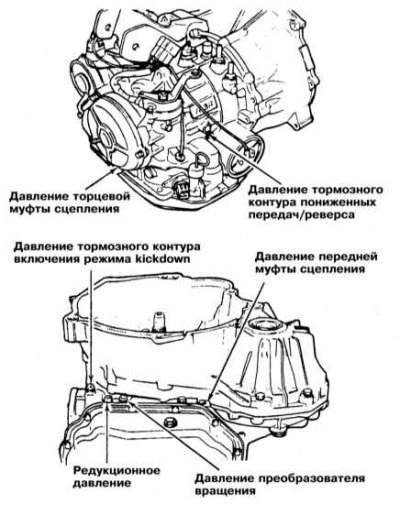

5. Find the fittings for connecting the pressure gauge on the side walls of the transmission housing, near the line of its articulation with the pallet. Unscrew the plug and connect the adapter of the meter to the appropriate fitting.

Note. For some measurements, a pressure gauge with a scale of up to 28 kgf / cm is required2 (see specs).

|  |

6. Make measurements of hydraulic pressure АТ at various turns of the engine and in various positions of the selector lever. Compare the measurement results with the requirements of the Specifications. If necessary, make appropriate adjustments, replace defective components.

7. After completing the measurements, tighten the plugs of the fittings with the required force.

Analysis of Line Pressure Test Results

Transmission F3А21

1. Excessively low pressure in positions "D", "L" And "2" with normal readings in position "R" indicates the presence of leaks in the rear clutch circuit, or through the accumulator 1-2 O-ring.

2. Low pressure in positions "D" And "R" normally in position "L" indicates a leak in the front clutch circuit.

3. Low pressure in positions "D" And "L" in normal position "2" is evidence of leaks in the downshift/reverse circuit.

4. Reduced pressure in all modes may indicate a malfunction of the oil pump, loosening of the valve assembly mounting bolts, filter obstruction or jamming of the pressure regulator valve.

F4A20 series transmissions (F4A22 and F4A23/33/51)

1. The reasons for under/overpressure in all lines may be: oil filter obstruction, control regulator settings violation, pressure regulator valve jamming, incorrect oil pump relief pressure, ATF leaks in the valve assembly.

2. Incorrect reducing pressure may indicate a blockage in the pressure reducing filter, a jammed pressure reducing valve, or the development of leaks in the valve assembly.

3. Incorrect pressure in the line of the brake circuit of the kickdown mode indicates a malfunction of the mode servo drive, or a failure of the valve assembly.

4. Incorrect front clutch pressure readings can be caused by: ATF leaks in the kickdown servo or valve assembly, valve assembly failure, piston or clutch carrier leaks.

5. Incorrect coupling pressure indicates ATF leakage at the coupling/valve assembly, or a malfunction of the latter.

6. Incorrect low/reverse brake line pressure indicates ATF leaks between valve assembly and transmission case (sealing ring), failure of the valve assembly or leakage through the piston or holder of the corresponding brake assembly.

7. The reasons for incorrect readings when measuring the pressure of the rotation converter may be: ATF leaks in the oil cooler or lines of the connecting path, malfunction of the converter, leaks through the input shaft seal, jamming of the converter clutch solenoid valve (TCCSV valve), or converter control valve failure.

Control Regulator Pressure Test (transmission F3А21)

1. The need to perform this check arises only in the event of a violation of the correctness of the moments of transmission shifting. Throttle cable adjustment must not be disturbed.

2. Connect a pressure gauge to the appropriate fitting on the transmission case.

3. Read the meter in position "D" transmission. Compare the measurement results with the requirements of the Specifications.

4. The cause of pressure deviations at a given vehicle speed may be a jamming of the control regulator valve, or a violation of the regulator filter.

5. The control regulator should promptly and smoothly respond to the measurement of speed and return to the base pressure (0÷20 kPa) when the vehicle is stopped.

Sea trials

Attention! The tests shall be carried out at normal operating temperature (50÷80°C) ATF.

Note. Moments of switching modes of the transfer case (H2, H4 and L 4) are different, in addition, in the L4 mode, the inclusion of 4th gear and the blocking of the torque converter are prohibited.

Range check "D" in normal and sport modes of operation

1. Move the AT selector lever to position "D", depress the accelerator pedal as far as it will go and hold it in this position. Check the shift points 1-2, 2-3 and 3-4, - compare the results of the check with the requirements of the Specifications.

2. Check is made for the normal and sports modes of functioning AT.

3. The absence of switching 1-2 indicates the failure of the electromagnetic valve No. 2, or the sticking of the valve 1-2.

4. Solenoid valve No. 1 is responsible for the lack of switching 2-3, and the possibility of sticking the switching valve 2-3 is also possible.

5. If there is no switching 3-4, check the condition of valve 3-4.

6. The reason for the failure of the shift points may be a malfunction of the throttle and shift valves 1-2/2-3/3-4.

7. The lack of torque converter lockup is due to the failure of the solenoid valve No. 3, or sticking of the lock-on valve.

8. Evaluate the smoothness of the gear shift. The cause of the shocks may be excessively high pressure in the main line, a malfunction of the hydraulic accumulator, or a control ball valve.

9. When driving with a locked torque converter or in 4th gear, evaluate the intensity of vibrations and background noise.

Note. The reason for the occurrence of vibrations and noises can also be a violation of the balance of the cardan shaft.

10. Accelerate the car to 4th gear and, while braking, determine the shift points 4-3, 3-2 and 2-1. compare the test results with the requirements of the Specifications.

11. Evaluate the smoothness of downshifts.

12. Check the quality of the torque converter blocking, - with a uniform movement in 4th gear, blocking should occur at a speed of approximately 75 km / h. Slightly press the gas pedal - the engine speed should not change noticeably, otherwise the torque converter lock is broken.

Range check "2"

1. Move the AT selector lever to position "2", depress the accelerator pedal as far as it will go and hold it in this position.

2. Determine the switching point 1-2, compare the test result with the requirements of the Specifications.

Note. In this mode, switching 2-3, 3-4 and blocking the torque converter are prohibited; when driving at a speed of 100 km / h and above, engine braking is prohibited.

3. While moving in 2nd gear, release the gas pedal and evaluate the effectiveness of engine braking of the car. If there is no braking, then the brake for providing this mode is faulty.

Range check "L"

1. When you turn on the mode "L" any upshifts are prohibited - the car must move all the time in first gear.

2. Release the gas pedal and evaluate the intensity of engine braking. If there is no braking, then the brake for engaging the first and reverse gears is faulty.

3. Assess the level of noise and vibration during engine braking.

Range check "R"

Move the AT selector lever to position "R" and start moving with the gas pedal pressed to the stop, - there should be no slippage of the friction controls.

Range check "R"

Park the vehicle on a slope of at least 5°and move the selector lever to the "R", do not apply the parking brake - the vehicle must remain stationary.