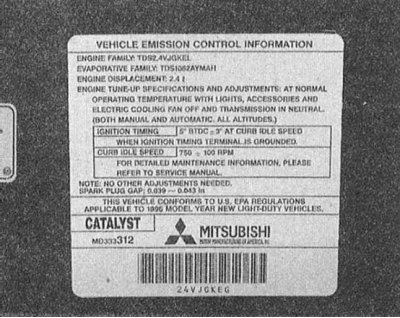

The VECI label is attached under the hood and contains information on emission control systems

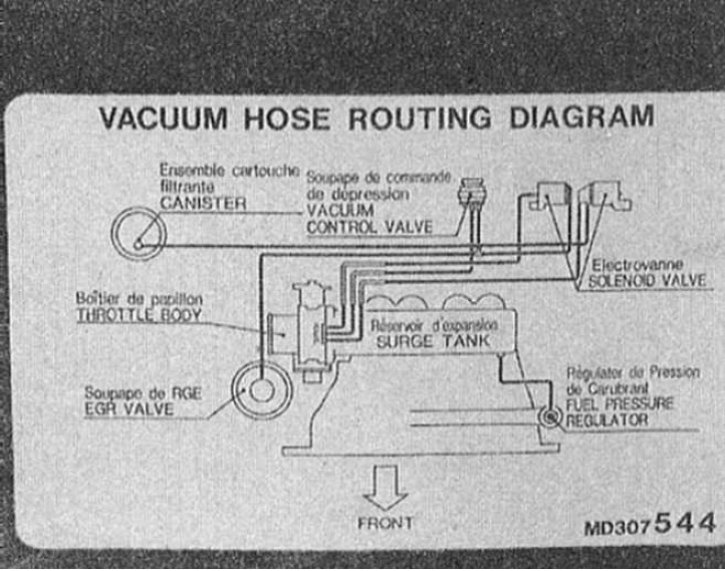

The layout of the vacuum lines is usually given on a separate label attached next to the VECI

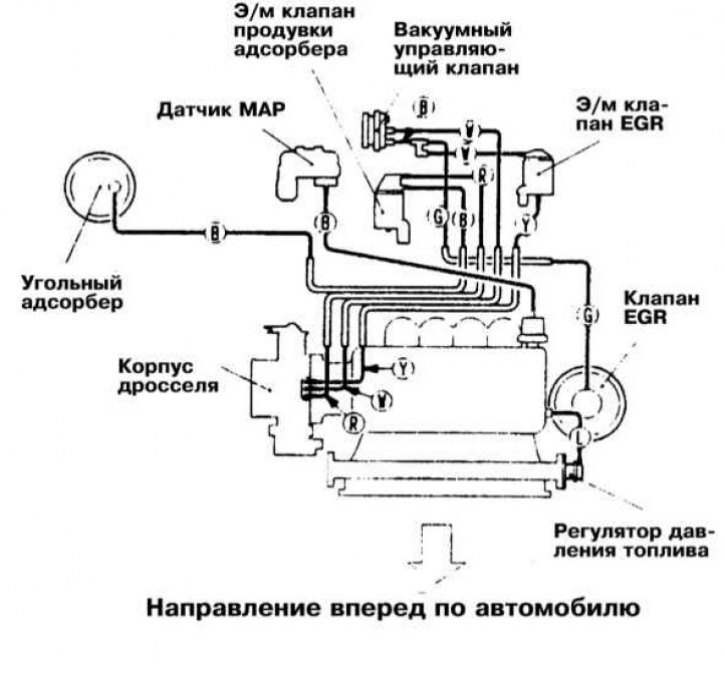

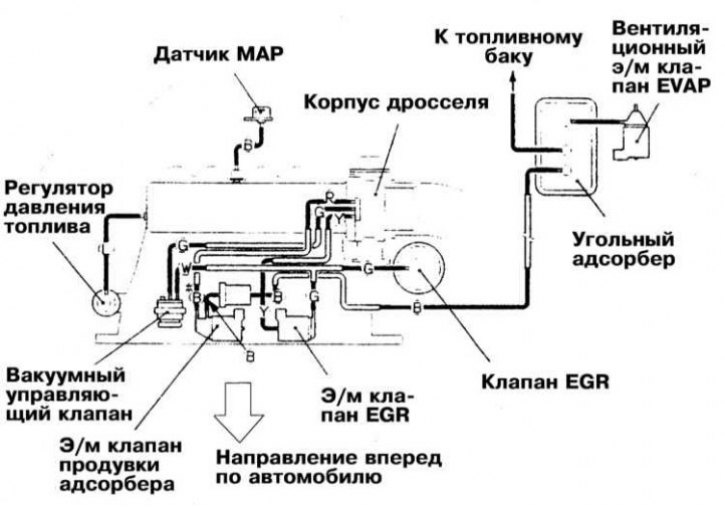

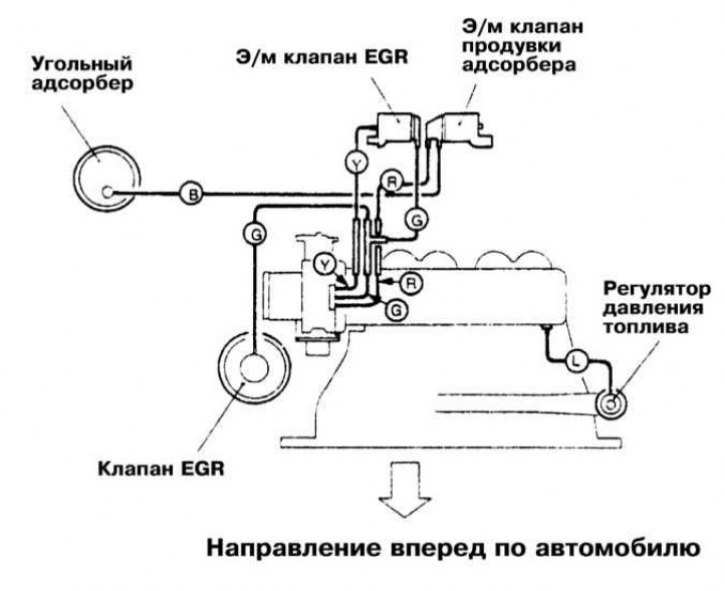

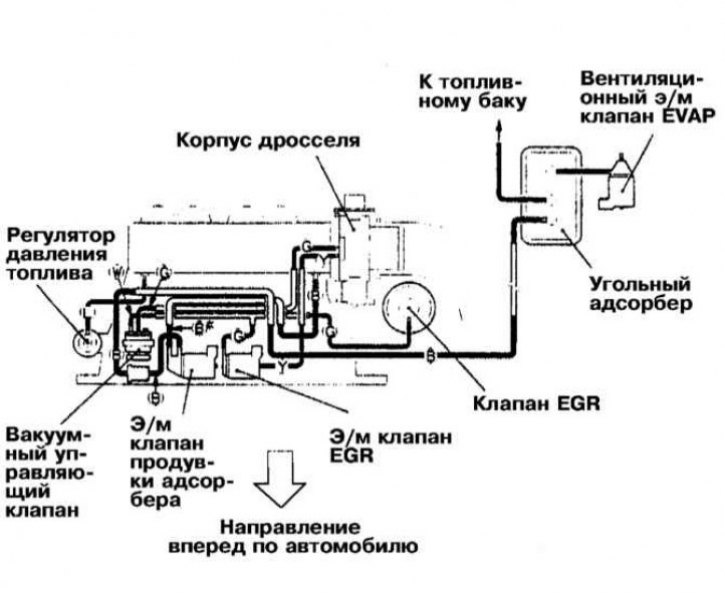

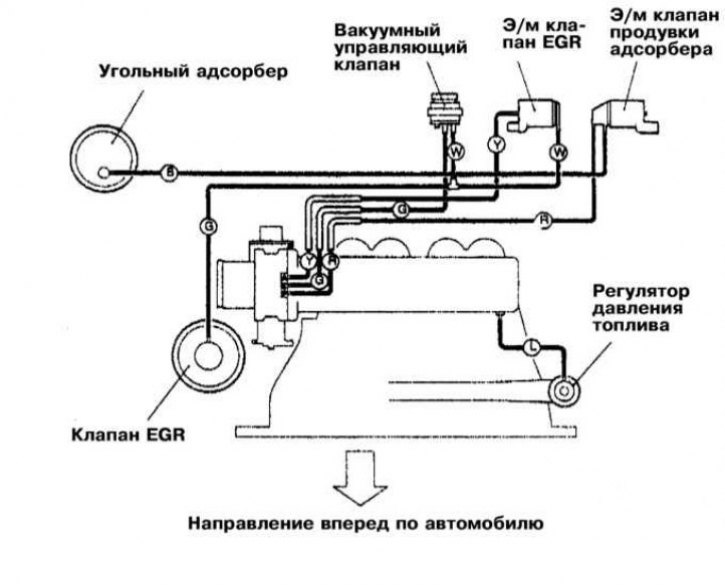

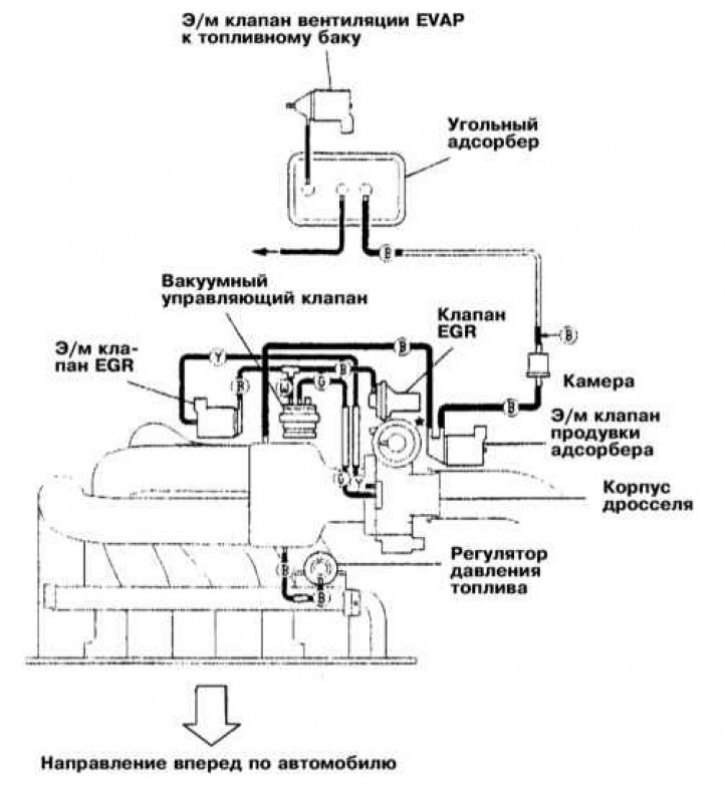

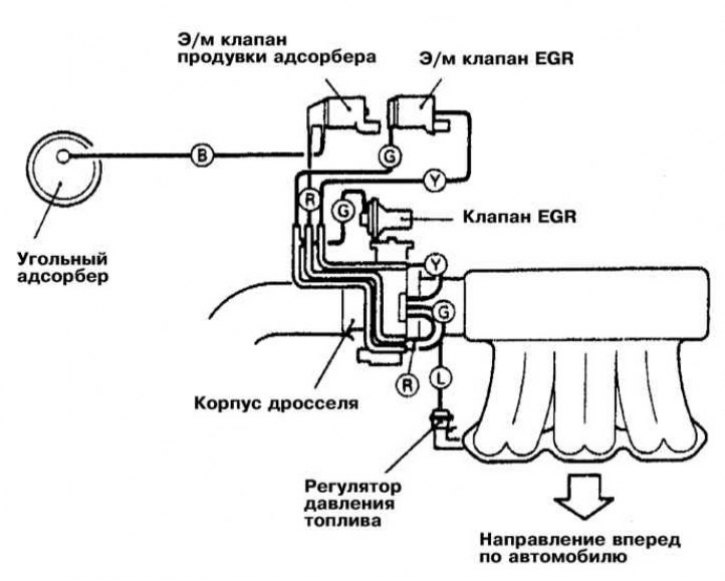

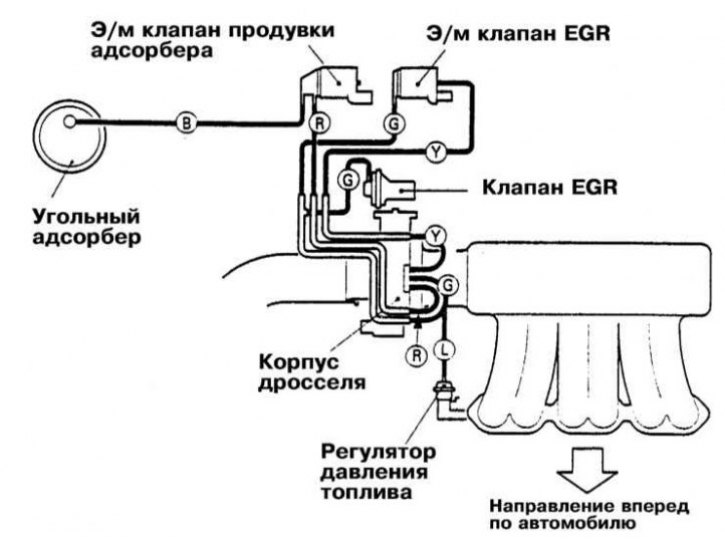

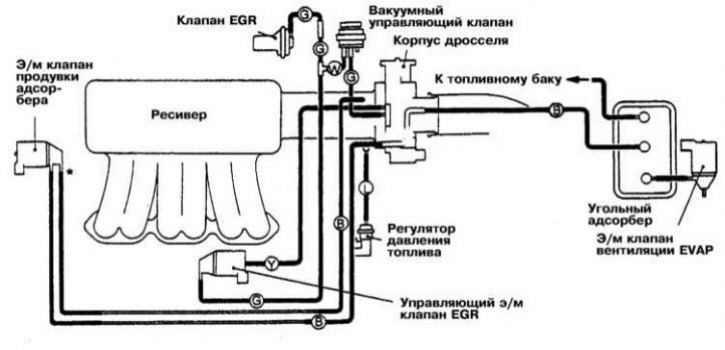

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on federal models 1.5 l 1990÷1992. issue

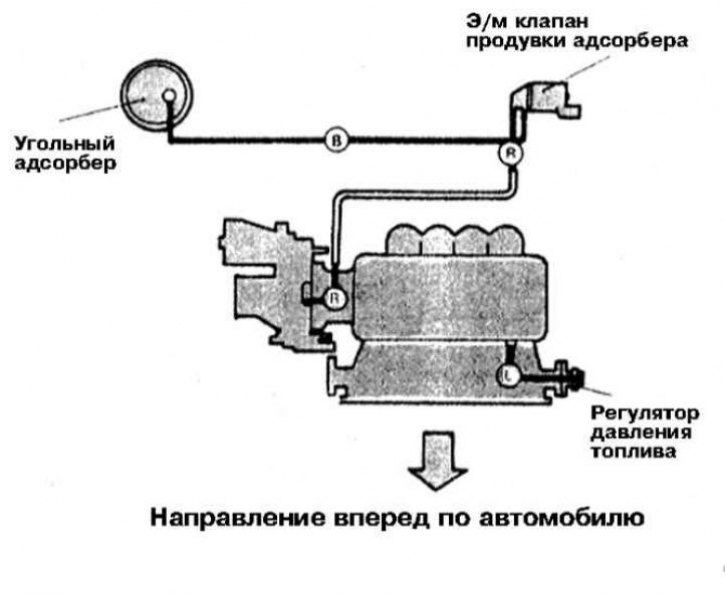

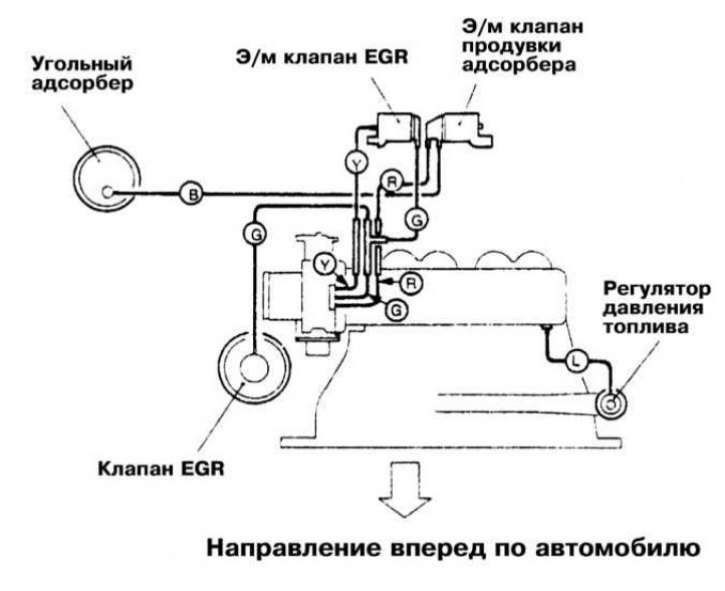

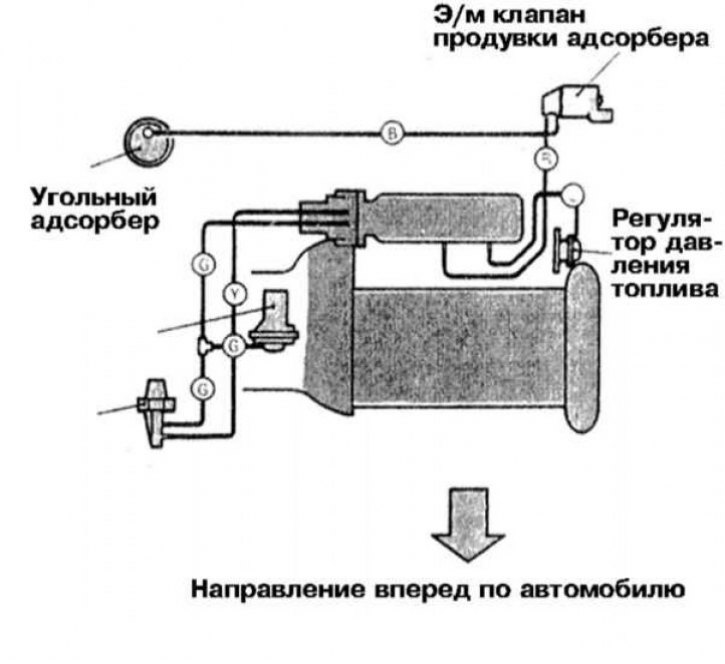

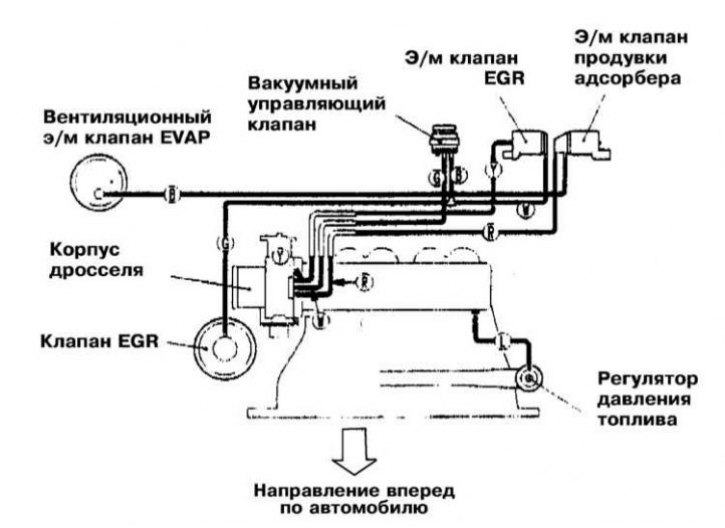

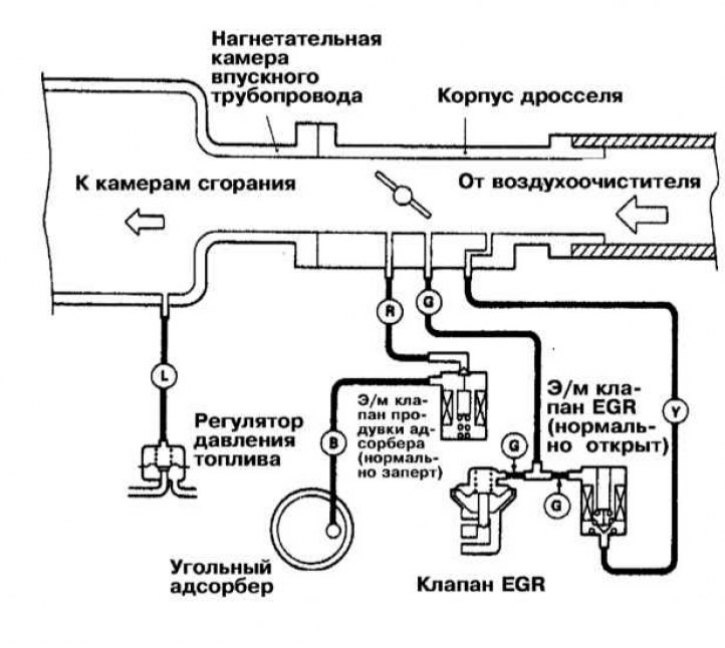

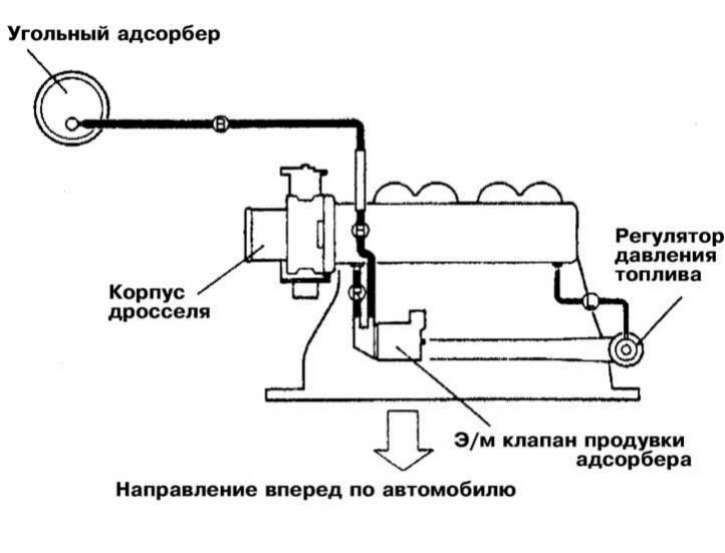

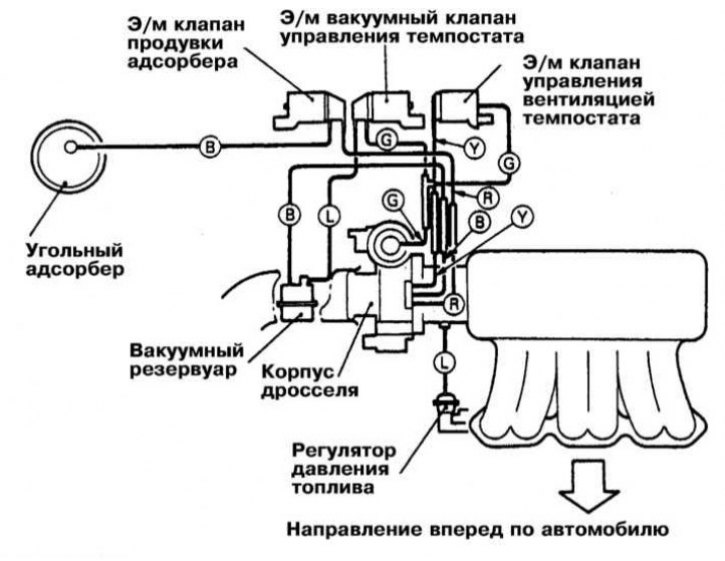

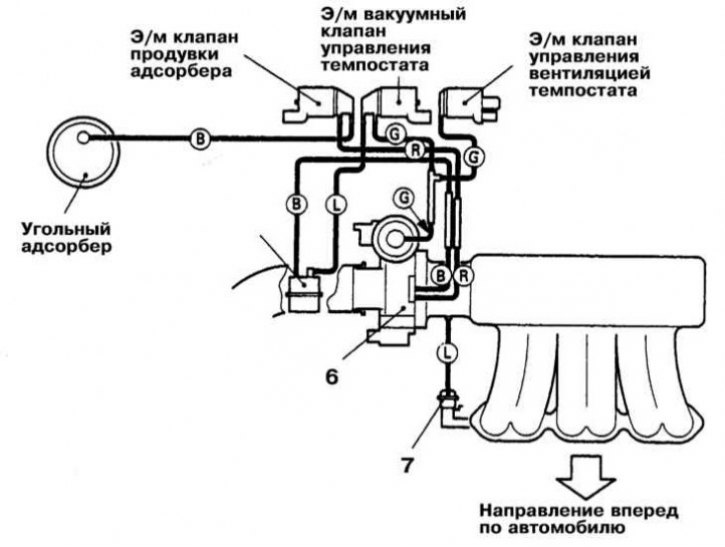

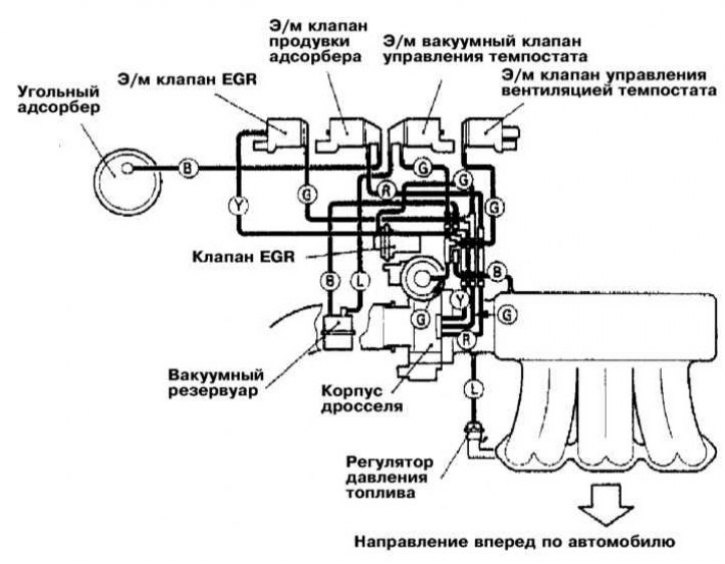

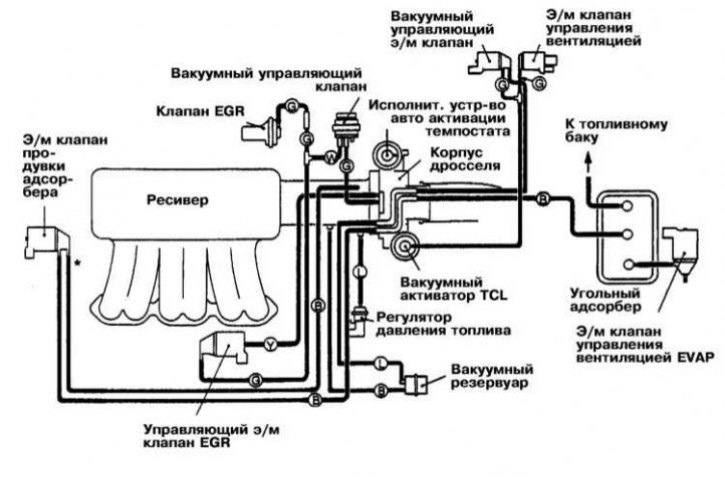

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on federal models 1.5 l 1993 vol.

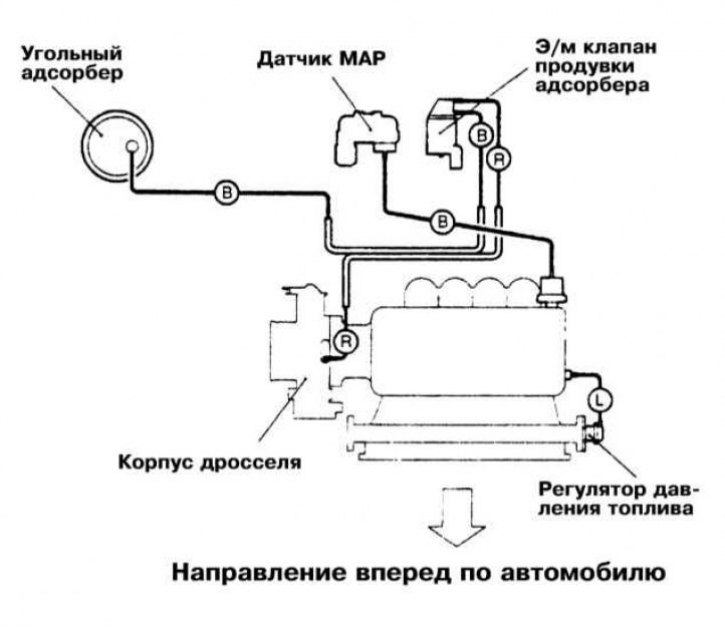

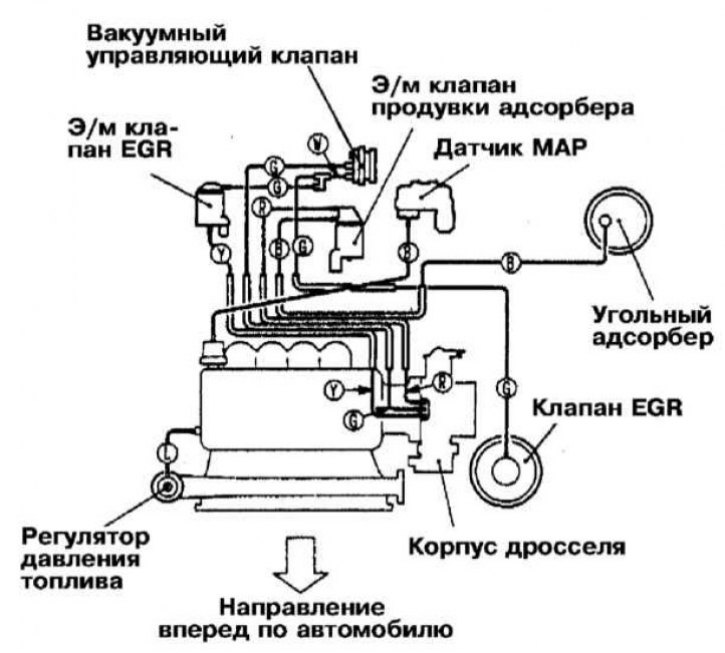

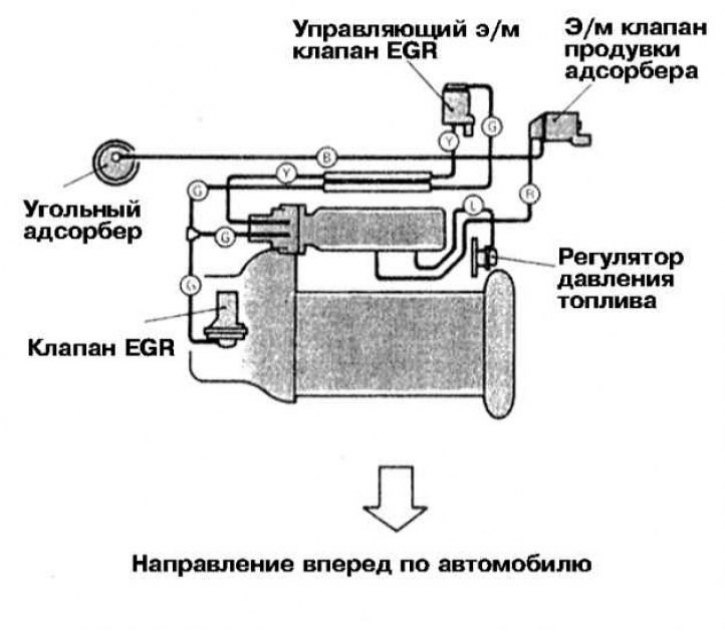

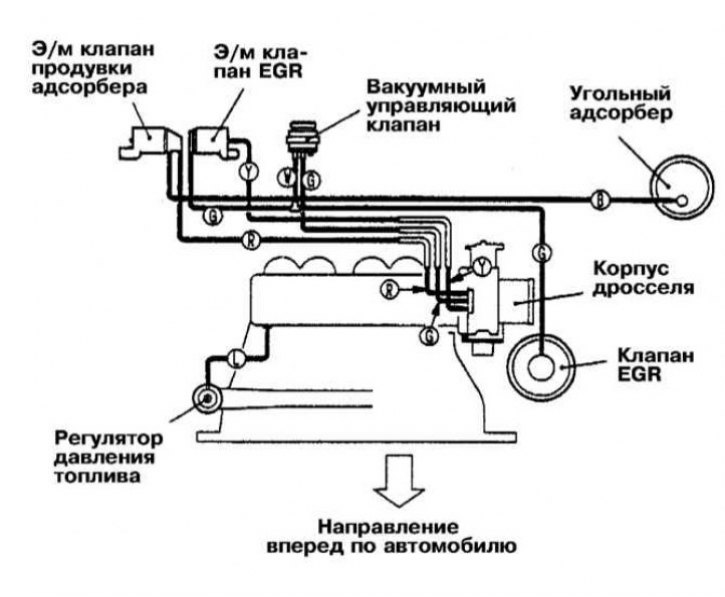

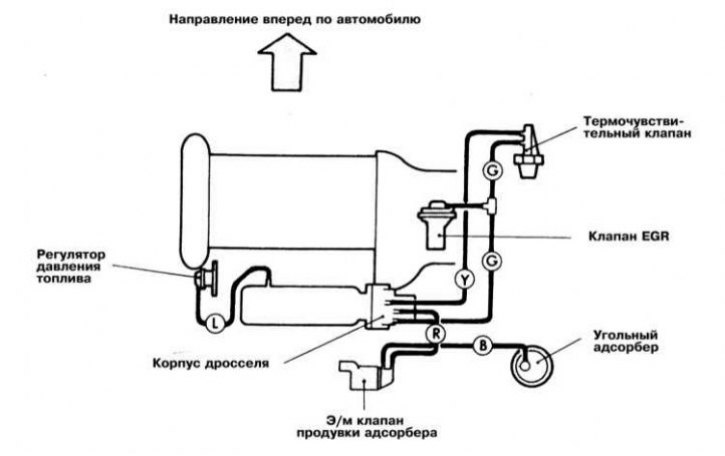

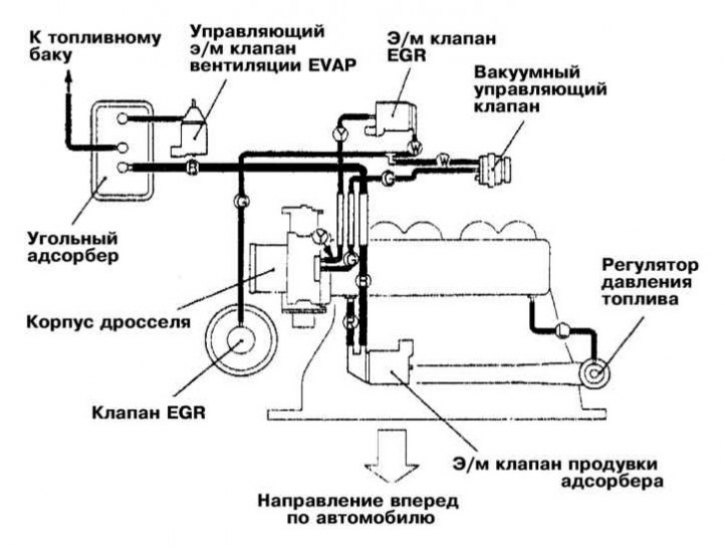

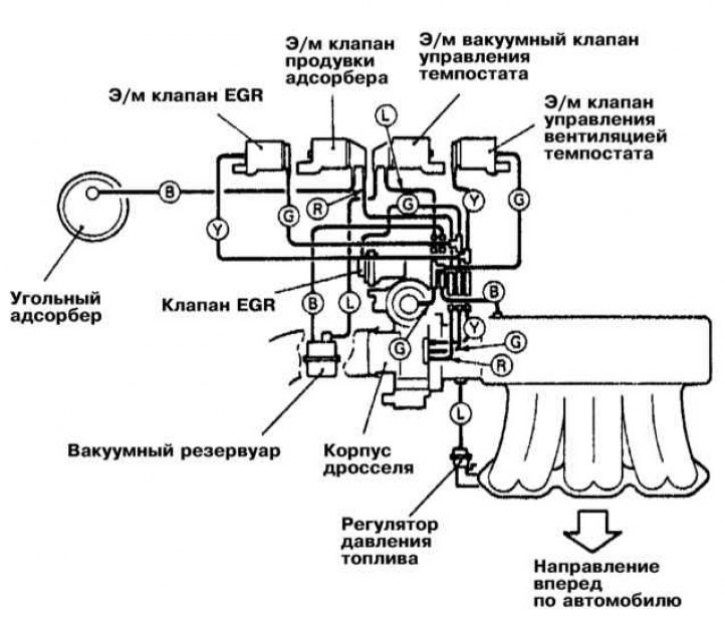

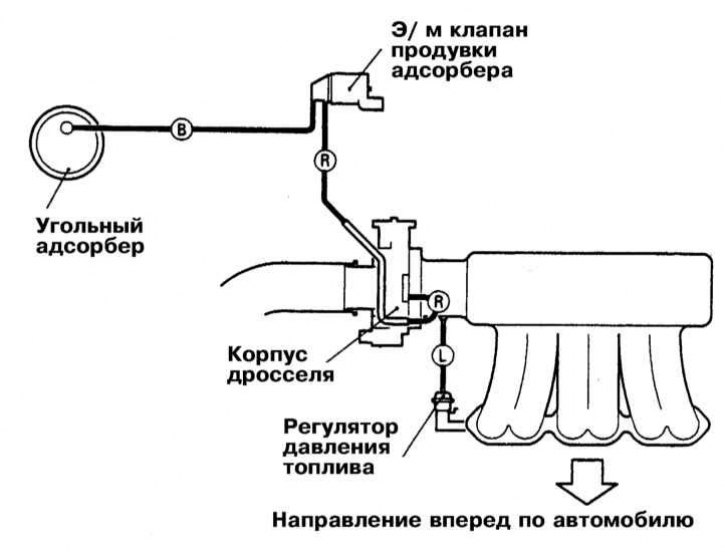

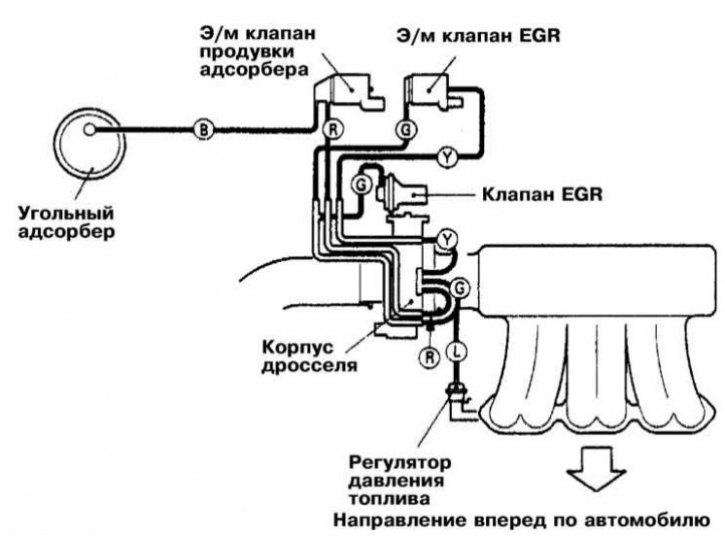

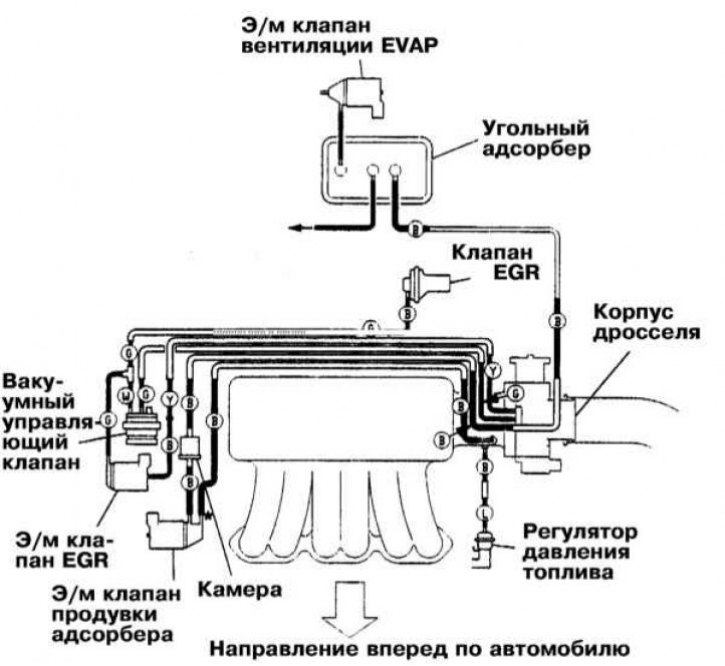

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on Californian models 1.5 l 1993 vol.

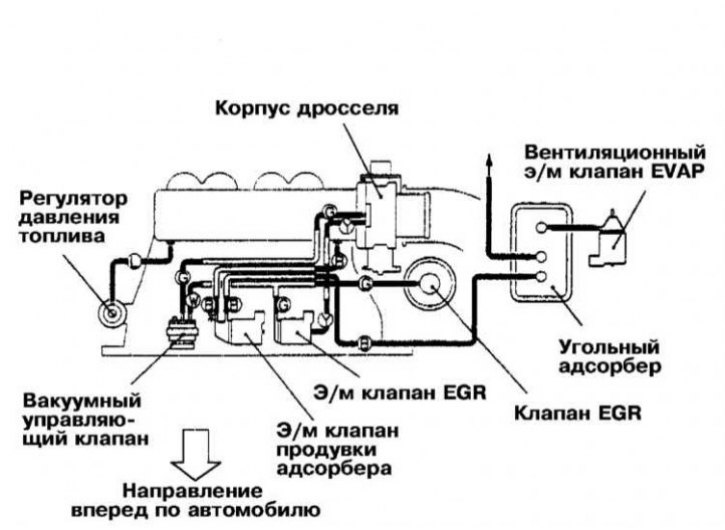

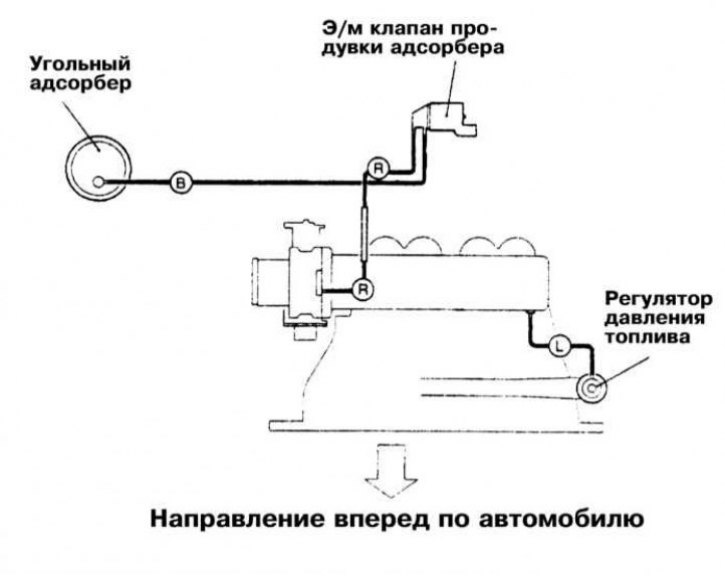

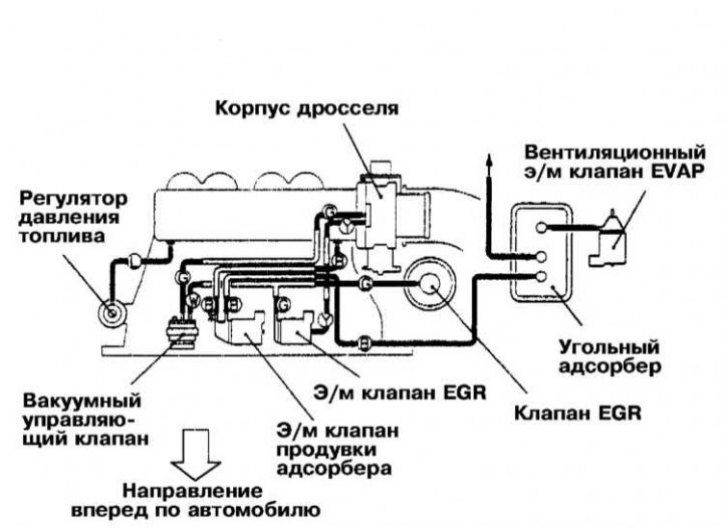

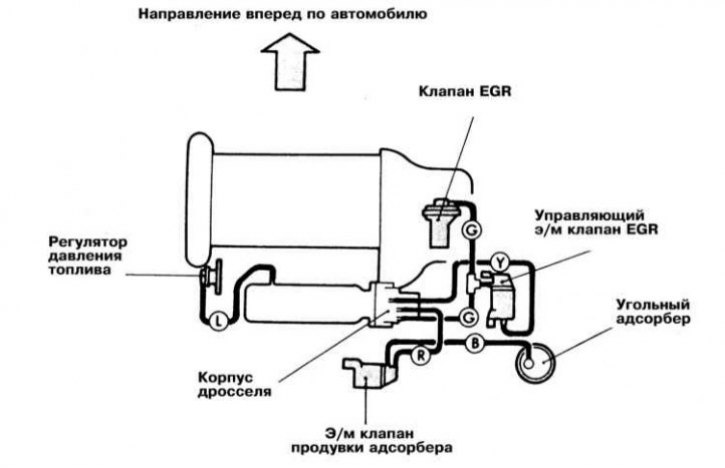

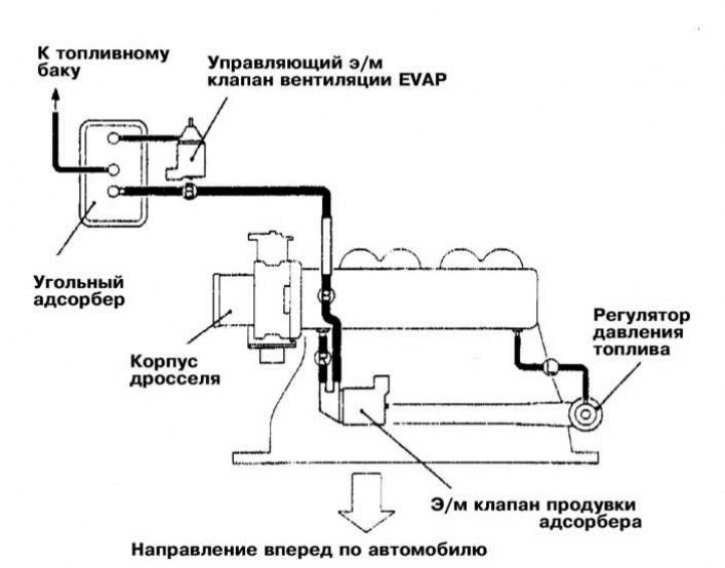

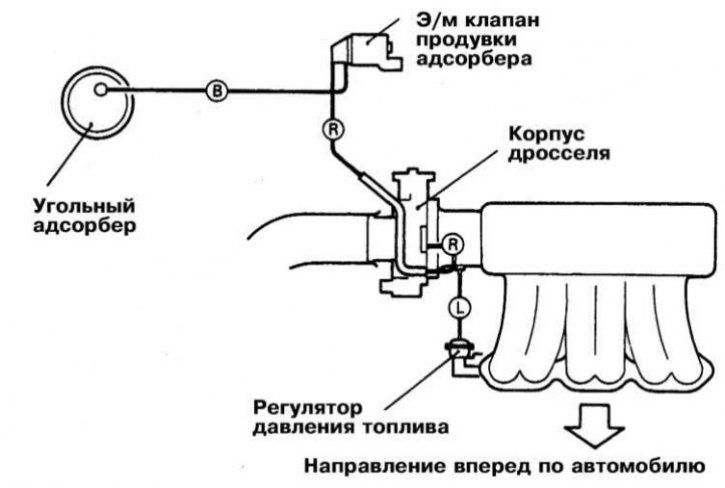

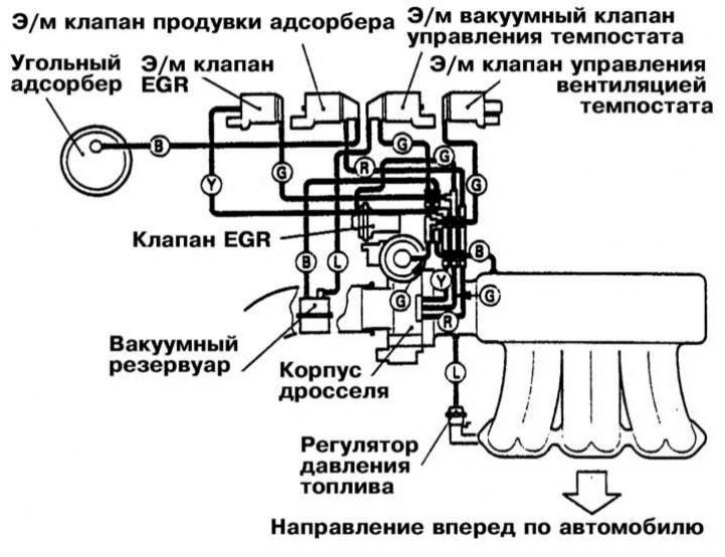

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on all models 1.5 l 1994÷1996. issue

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on all models 1.5 l 1997 vol.

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on all models 1.5 l 1998 vol.

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on all models 1.5 l since 1999 vol.

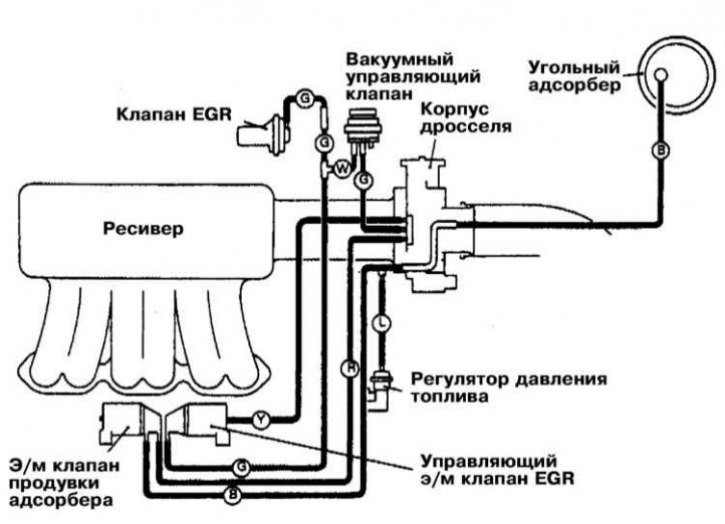

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on federal models 1.6 l 1990÷1992. issue

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on Californian models 1.6 l 1990÷1992. issue

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on federal models 1.8 l 1993 vol.

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on all models 1.8 l 1994÷1996. issue and California models 1.8 L

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on Californian models 1.8 l 1995 and 1996. issue

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on all models 1.8 l 1997 vol.

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on all models 1.8 l 1998 vol.

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on all 1.8 liter models since 1999 vol.

Diagram of laying vacuum hoses for emission control systems on federal models 2.0 l (SOHC) 1990÷1993 issue

Diagram of laying vacuum hoses for emission control systems on federal models 2.0 l (SOHC) 1990÷1993 issue

Diagram of laying vacuum hoses for emission control systems on federal models 2.0 l (DOHC) 1990 issue. without turbo

Laying diagram of vacuum hoses of systems for reducing the toxicity of exhaust gases on California models 2.0 l (DOHC) 1990 issue. without turbo

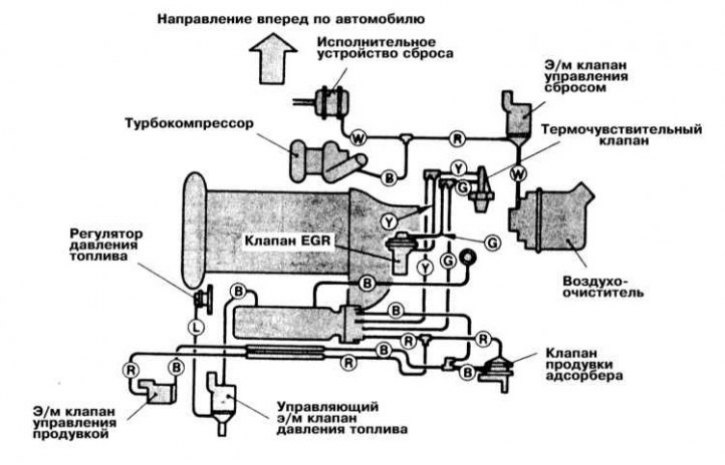

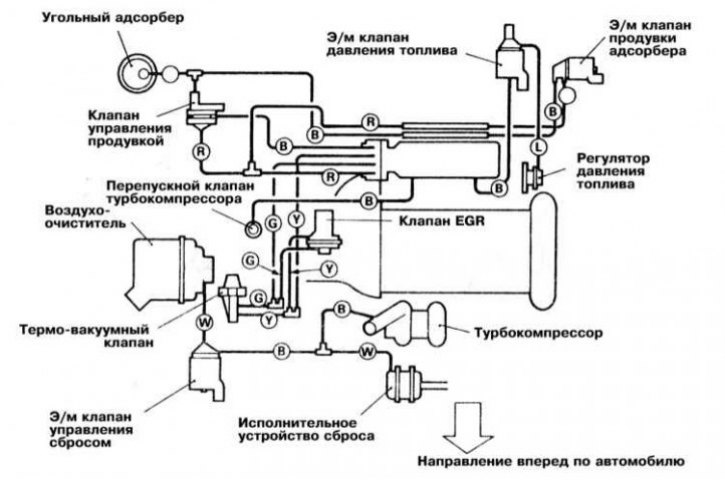

Diagram of laying vacuum hoses for emission control systems on federal models 2.0 l (DOHC) 1990 issue. turbocharged

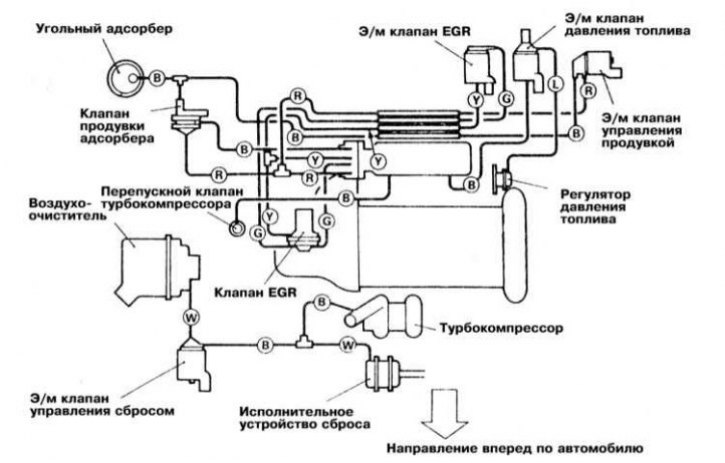

Laying diagram of vacuum hoses of systems for reducing the toxicity of exhaust gases on California models 2.0 l (DOHC) 1990 issue. turbocharged

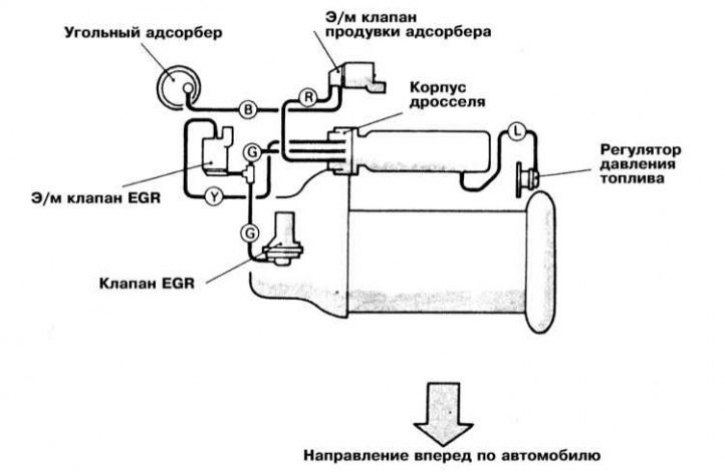

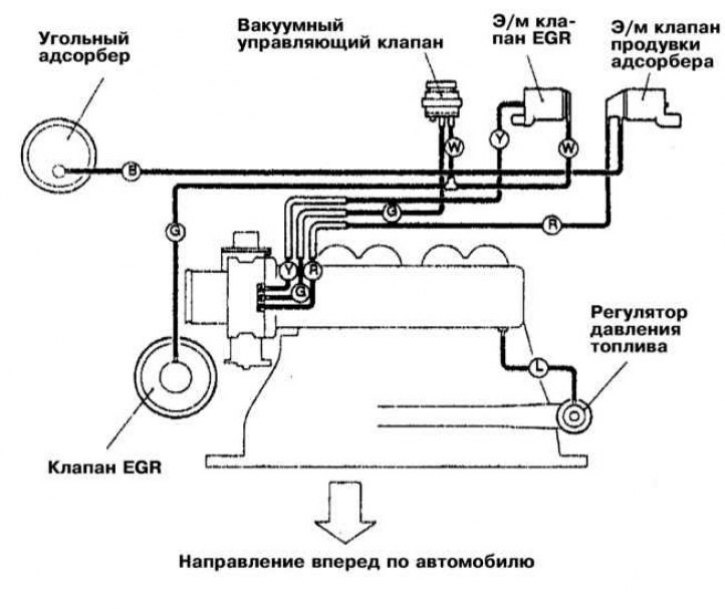

Diagram of laying vacuum hoses for emission control systems on federal models 2.0 l (DOHC) 1991÷1993 issue without turbo

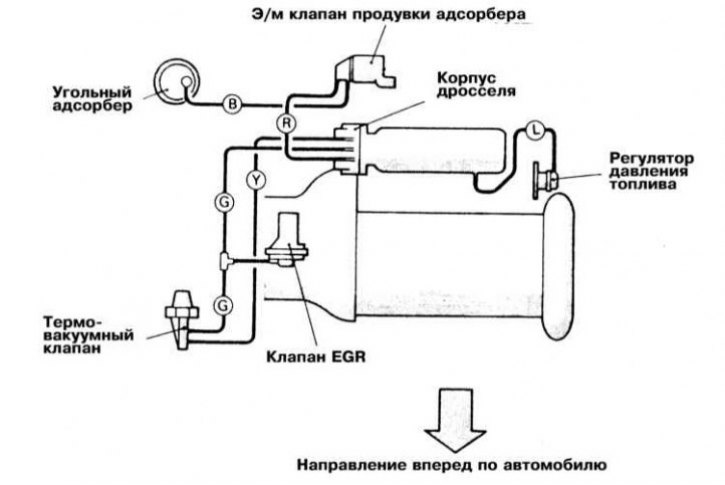

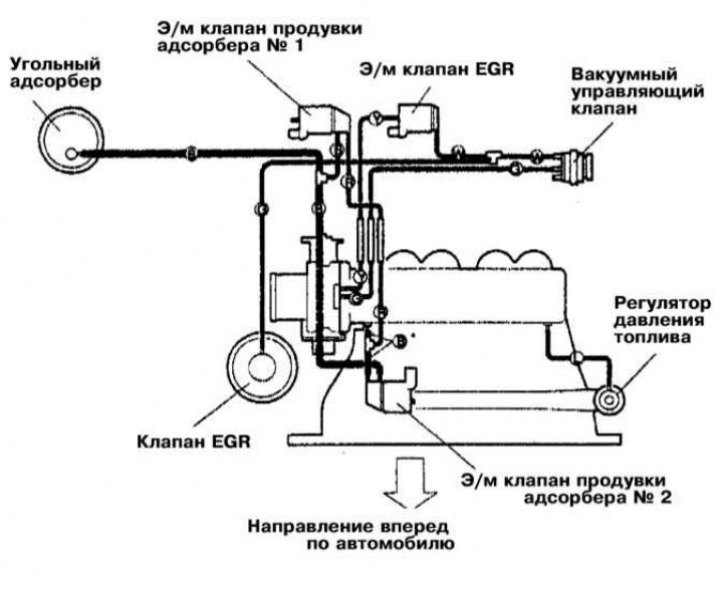

Laying diagram of vacuum hoses of systems for reducing the toxicity of exhaust gases on California models 2.0 l (DOHC) 1991÷1993 issue without turbo

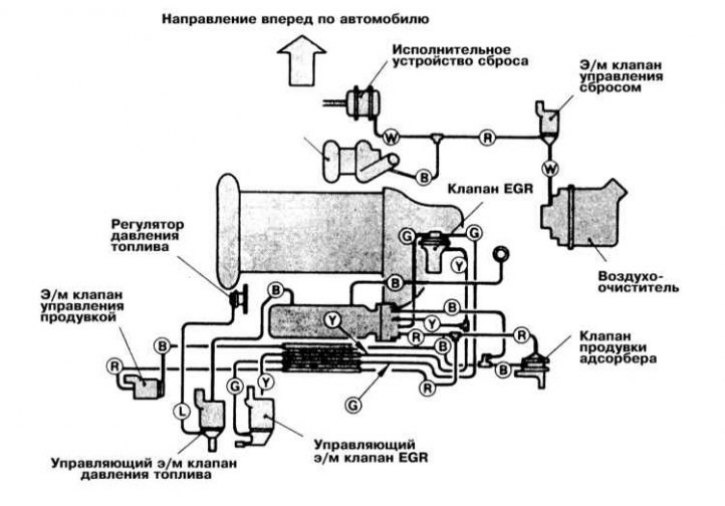

Diagram of laying vacuum hoses for emission control systems on federal models 2.0 l (DOHC) 1991÷1993 issue turbocharged

Laying diagram of vacuum hoses of systems for reducing the toxicity of exhaust gases on California models 2.0 l (DOHC) 1991÷1993 issue turbocharged

Laying diagram of vacuum hoses for emission control systems on federal models 2.4 l (DOHC) 1994÷1996 issue

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on California models 2.4 l (DOHC) 1994÷1996 issue

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on federal models 2.4 l 1997 vol.

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on California models 2.4 l (DOHC) 1997 issue.

Laying diagram of vacuum hoses for emission control systems on federal models 2.4 l (DOHC) 1998 issue.

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on California models 2.4 l (DOHC) 1998 issue.

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on 2.4 l models (DOHC) since 1999 issue.

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on federal models 3.0 l 1992 vol. with anti-slip system

Scheme for laying vacuum hoses of exhaust gas toxicity reduction systems on California models 3.0 l 1992 vol. with anti-skid system

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on federal models 3.0 l 1992 vol. without traction control

Scheme for laying vacuum hoses of exhaust gas toxicity reduction systems on California models 3.0 l 1992 vol. without traction control

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on federal models 3.0 l 1993 and 1994 issue with anti-slip system

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on federal models 3.0 l 1993 and 1994 issue without traction control

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on federal models 3.0 l 1995 and 1996 issue with anti-slip system

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on federal models 3.0 l 1995 and 1996 issue without traction control

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on Californian models 3.0 l 1993÷1996. issue with anti-slip system

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on Californian models 3.0 l 1993÷1996. issue without traction control

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on models 3.5 l 1997 vol.

Scheme of laying vacuum hoses of systems for reducing the toxicity of exhaust gases on models 3.5 l 1998 vol.

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on 3.5 liter models since 1999, no. with anti-slip system

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on 3.5 liter models since 1999, no. without traction control.

Scheme of laying vacuum hoses of exhaust gas toxicity reduction systems on 3.0 liter models since 1999 vol. with anti-slip system.

In order to reduce the emission of toxic components into the atmosphere that enter the composition of the exhaust gases of the engine as a result of evaporation and incomplete combustion of the fuel, as well as to maintain the efficiency of the engine output and reduce fuel consumption, the vehicles covered in this manual are equipped with a number of special systems that can be combined under the general name of engine management systems and reducing the toxicity of exhaust gases. The complete set of systems depends on the year of manufacture of the models and the region in which the car is supplied to the market. Full information on the type of composition of the systems is given on the VECI information label fixed under the hood.

Note. The hose routing diagram can be shown on a separate nameplate.

Schemes for laying vacuum hoses of exhaust gas toxicity reduction systems for various models are presented in the accompanying illustrations 1.2a÷1.2av.

Note. The illustrations use the following color codes: B = Black; G = Green; L = Blue; R = Red; Y = Yellow; * = with red marking.

Systems/components related to engine management and emission control include the following:

- a) Controlled crankcase ventilation system (PCV);

- b) Evaporative Emission System (EVAP);

- c) Exhaust gas recirculation system (EGR);

- d) Idle stabilization system (IAC);

- e) On-Board Diagnostic System (OBD);

- f) catalytic converter.

Note. More detailed information on the engine management and emission control systems of your vehicle can be obtained from the representative office of the manufacturer.

The functioning of all these systems, one way or another, directly or indirectly, is related to the management of the reduction of exhaust gas toxicity. The following Sections provide general descriptions of how each system operates, as well as procedures for diagnostic checks and remedial repairs (if it is possible) individual components, the performance of which lies within the qualifications of the average amateur mechanic.

Before coming to the conclusion that any of the emission control systems have failed, carefully check the power and ignition systems for proper functioning (see chapters Power and exhaust systems and Engine electrical equipment). Diagnostics of some of the components of toxicity reduction systems requires the use of special, difficult-to-use equipment and a certain qualification of the performer, and therefore, it would be reasonable to entrust its implementation to professional mechanics of a specialized service station. The foregoing does not mean that the maintenance and repair of components of toxicity reduction systems in practice seem difficult. It should be remembered that one of the most common causes of failures is an elementary violation of the quality of vacuum or electrical contact connections, and therefore, first of all, you should always check the condition of electrical connectors and union connections of vacuum lines. The owner of the car can independently and quite easily perform a number of checks, as well as perform many routine maintenance procedures for most system components at home, using the usual set of tuning and locksmith tools.

Note. Be aware of additional federal warranties that apply to emission control and engine management components. Before proceeding with any procedures for the repair of components and parts of these systems, consult the conditions for compliance with these obligations at the representative office of Mitsubishi.

Try to observe all the precautions specified in the following Sections when performing maintenance of the electronic components of the systems in question. It should be noted that the illustrative material may not always exactly match the actual placement of components on the vehicle. Such inconsistencies are associated with the ongoing process of modification within the framework of the typical design of each model.