Attention! When performing maintenance procedures in the engine compartment with the engine running, use extreme caution - try not to touch moving components (drive belts, fan impeller, etc.) and prevent hair and clothing from getting into them.

Analysis of test results

All injectors click properly

1. If all injectors click properly and, nevertheless, there are suspicions of a malfunction in the power system, continue with the diagnosis.

2. Check the pressure characteristic of the fuel pump (see below).

3. Check the ignition system. Alternately disconnecting (and connecting back) HV wires from each of the spark plugs with the engine idling, try to localize the faulty cylinder by the absence of a violation of the stability of the revolutions.

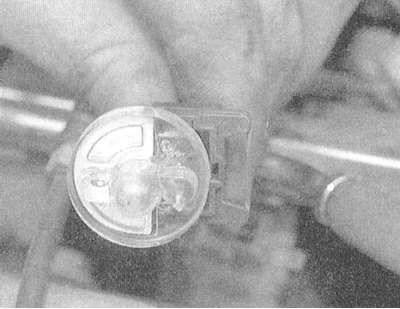

4. Remove the fuel injection injector to the suspect cylinder and transfer it to a workbench (the fuel line assembly can be removed). To check the injection pattern, connect the fuel supply line to the injector and briefly apply a voltage of 12 V DC to its terminals (grounding is carried out through the body of the injector): a cone-shaped jet of fuel should be ejected through the valve nozzle. A defective injector must be replaced.

One or more injectors do not click

1. Prepare a special probe lamp. Switch off the ignition and disconnect the electrical wiring from the injector to be checked. Connect the test lamp to the injector wiring harness connector and start the engine: the flashing of the lamp confirms that the control voltage is being supplied to the injector.

|  |

|

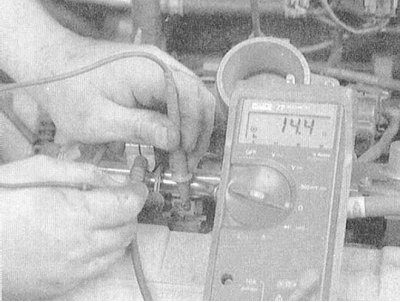

2. If there are no power failures, measure the resistive resistance of the injector. Compare the measurement result with the requirements of the Specifications (for normal suction engines the nominal value lies within the range of 13÷16 ohms, at 20°C, for turbocharged engines the required range is 2÷3 ohms [at the same temperature]).

3. If during testing with a probe lamp signs of failures in the supply of control voltage are detected, the condition of the corresponding electrical circuit should be checked. Disconnect the negative cable from the battery.

Attention! If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system! Disconnect the probe lamp from the injector. Also disconnect the wiring from the PCM. Check the condition of the wiring in the section of the circuit between the PCM and the injector: the resistive resistance between the corresponding pins of the connectors should be about 5 ohms. If the test results are negative, make the necessary reconditioning of the electrical wiring.

4. If the circuit is OK, then there is an internal PCM failure and the control module needs to be replaced.