Engines 1.5 l

Removing

1. Relieve pressure in the supply system.

Remember that gasoline is a highly flammable liquid! Observe all applicable fire safety precautions when working on power system components. Do not smoke! Do not approach the place of work with an open flame or carrying an unprotected lampshade! Do not service the system in rooms equipped with natural gas-fired heaters equipped with a pilot flame (such as water heaters and clothes dryers). Do not forget that gasoline is classified as a carcinogen, i.e., substances that contribute to the development of cancer! Try to avoid getting fuel on open areas of the body, use rubber protective gloves, in case of accidental unexpected contact with fuel, thoroughly wash your hands with warm water and soap. Clean up spilled fuel immediately and do not store fuel-soaked rags near open flames. Remember that the fuel injection system of models equipped with fuel injection is constantly under pressure. Relieve any residual pressure in the system before attempting to disconnect fuel lines. Wear safety goggles when servicing power system components. Keep a class B fire extinguisher handy at all times!

2. Disconnect the negative cable from the battery.

If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

3. Empty the cooling system.

To avoid burns, proceed with the above work only after the system has completely cooled down! Do not allow antifreeze to come into contact with exposed areas of the body and painted surfaces of the car. Accidental splashes should be washed off immediately with plenty of water. Remember that antifreeze is a highly toxic liquid and getting it into the body, even in small quantities, is fraught with the most serious consequences (up to death). Never leave antifreeze stored in a loosely sealed container and clean up spilled coolant on the floor without delay. Remember that the sweet smell of antifreeze can attract the attention of children and animals. Consult any car service station about ways to dispose of used coolant. In many regions of the world, special points have been set up to receive various types of detention. Never drain old coolant down the drain and onto the ground!

4. Remove the air cleaner assembly with the air intake sleeve.

5. Disconnect the ground bar and throttle cable.

6. Disconnect the breather tube and crankcase ventilation hose (PCV).

7. Having previously marked, disconnect the vacuum hoses from the intake manifold and throttle body.

8. Disconnect the vacuum line from the brake booster servo assembly.

9. Remove the upper radiator hose, the hoses connected to the throttle body and the hoses of the interior heating system path.

10. Disconnect the fuel supply and return lines.

11. Remove the BB wiring.

12. Disconnect the wiring from the crankshaft position sensors (TFR) and distribution (SMR) shafts, oxygen sensor (O2), coolant temperature sensor (EATING) and sensor of the engine temperature meter, drive electric motor of the actuator of the idle speed stabilization system (ISC),throttle position sensor (TPS), intake air temperature sensor (IAT) and exhaust gas temperature sensor of the recirculation system (EGR).

13. Disconnect the electrical wiring from the ignition distributor, fuel injection injectors and power transistor. Remove the ground strap.

14. Disconnect the electrical wiring of the engine management system.

15. Remove the retainer for fastening the hose of the power steering system (power steering) on the bracket of the suspension support of the power unit.

16. Support the engine with a trolley jack (to distribute the load, lay a block of wood between the head of the jack and the oil pan). Cock the jack, fully unloading the suspension support of the power unit, then release the fasteners and remove the support bracket.

17. Remove the cylinder head cover.

18. Remove the top timing cover.

19. Having turned a cranked shaft clockwise, achieve alignment of adjusting marks.

20. Wire the timing belt to the camshaft gear.

21. Block the camshaft from turning and remove its gear wheel together with the toothed belt tied to it.

22. Remove the upper section of the rear timing cover.

23. Separate a reception pipe of system of release of the fulfilled gases from a final collector.

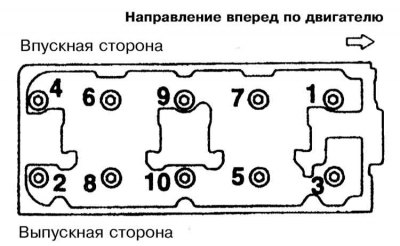

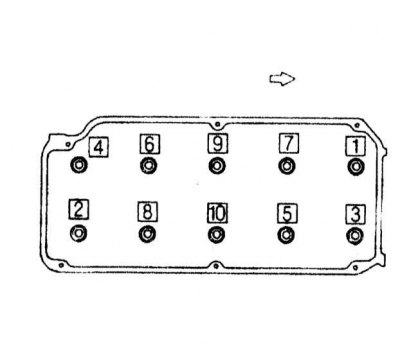

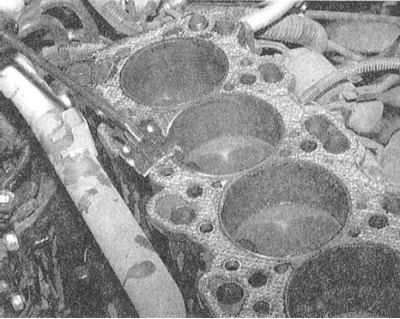

24. Acting strictly in a certain order, in three steps, loosen the head mounting bolts.

25. Remove the head from the cylinder block.

Installation

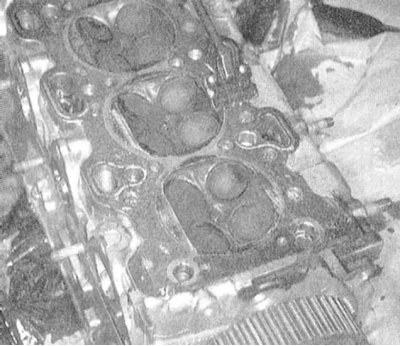

1. Thoroughly clean the mating surfaces of the head and cylinder block, completely removing traces of sealant and old gasket material from them. Finally, wipe the surfaces with a cloth soaked in acetone.

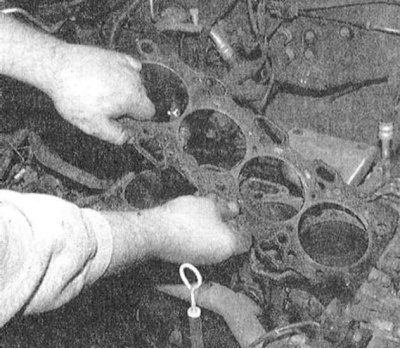

2. Place a new gasket on the block (identification mark up).

The gasket is laid dry, without the use of any sealants.

3. Carefully place the head on the block. Screw in the mounting bolts and, strictly in a certain order, in several stages, tighten them with the required force (see Specifications).

4. After replacing the gasket, connect the downpipe to the exhaust manifold.

5. Install the rear timing cover.

6. Having achieved the correct alignment of the alignment marks, reinstall the camshaft gear. Screw in the fixing bolt and tighten it to the required torque (70 Nm). Adjust the timing belt tension, then install the outer timing cover.

7. Reinstall the cylinder head cover. Screw in the mounting bolts and tighten them with the required force (1.8 Nm).

8. Establish an arm of a support of a suspension bracket of the power unit, lower a jack and take it from under the car.

9. Install the power steering hose retainer on the power unit suspension support bracket.

10. Connect the wiring to the CKP, CMP, O2, ECT, TP, IAT and EGR temperature sensors, as well as to the drive motor of the ISC actuator.

11. Connect the electrical wiring to the ignition distributor, fuel injection injectors and power transistor. Restore the original ground bus connection.

12. Connect a plait of electroconducting of a control system of the engine.

13. After replacing the O-rings, connect the fuel supply and return lines.

14. Install the air cleaner assembly. Connect the breather hose.

15. Fill the engine with fresh coolant (see chapter Settings and ongoing maintenance).

16. Connect the negative wire to the battery.

Engines 1.8 l

Removing

1. Relieve pressure in the supply system. Disconnect the negative cable from the battery.

If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

2. Remove the air cleaner assembly with the air intake sleeve.

3. Empty the cooling system.

To avoid burns, proceed with the above work only after the system has completely cooled down! Do not allow antifreeze to come into contact with exposed areas of the body and painted surfaces of the car. Accidental splashes should be washed off immediately with plenty of water. Remember that antifreeze is a highly toxic liquid and getting it into the body, even in small quantities, is fraught with the most serious consequences (up to death). Never leave antifreeze stored in a loosely sealed container and clean up spilled coolant on the floor without delay. Remember that the sweet smell of antifreeze can attract the attention of children and animals. Consult any car service station about ways to dispose of used coolant. In many regions of the world, special points have been set up to receive various types of detention. Never drain old coolant down the drain and onto the ground!

4. Disconnect the vacuum line from the brake booster servo assembly and the crankcase ventilation hose (PCV)

5. Having previously marked, disconnect the vacuum hoses from the intake manifold and throttle body.

6. Remove the upper radiator hose, overflow pipe, and hoses connected to the thermostat and throttle body.

7. Disconnect the fuel supply and return lines.

8. Disconnect the gas cable from the throttle body.

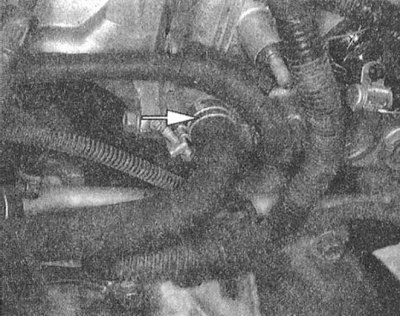

9. Disconnect the electrical wiring from the oil pressure switch.

10. Disconnect the electrical wiring from the oxygen sensor (O2), coolant temperature sensor (EATING) and sensor of the engine temperature meter, drive electric motor of the actuator of the idle speed stabilization system (additional air supply) (IAC),throttle position sensor (TPS), knock sensor and fuel injection injectors.

11. Remove spark plug wires.

12. Loosen and move the control wiring harness assembly aside.

13. Remove the thermostat housing and its O-ring.

14. Remove the cylinder head cover.

15. Remove the upper timing belt cover.

16. Having turned a cranked shaft clockwise, achieve alignment of adjusting marks.

17. Wire the timing belt to the camshaft gear.

18. Block the camshaft from turning and remove its gear wheel together with the toothed belt tied to it.

19. Remove the upper section of the rear timing cover.

20. Acting strictly in a certain order, in three steps, loosen the head mounting bolts.

21. Remove the head from the cylinder block.

Installation

1. Thoroughly clean the mating surfaces of the head and cylinder block, completely removing traces of sealant and old gasket material from them. Finally, wipe the surfaces with a cloth soaked in acetone.

2. Place a new gasket on the block (identification mark up).

The gasket is laid dry, without the use of any sealants.

3. Carefully place the head on the block.

4. Evaluate the condition of the mounting bolts, replace the bolts whose length exceeds 96.4 mm.

5. Before installation, lightly lubricate the threaded part of the bolts with liquid machine oil. Put washers under the heads (chamfer out).

6. Screw in the mounting bolts and, strictly in a certain order, in several stages, tighten them with the required force (see Specifications).

7. Install the camshaft gear, block it from turning with a suitable key, then screw in the mounting bolt and tighten it with the required force (90 Nm). Track the correct alignment of the installation marks.

8. Install the timing belt drive top cover and cylinder head cover. Tighten the bolts of the latter with a force of 3 Nm.

9. To facilitate installation of the thermostat housing, loosen the water pump mounting bolt.

10. Apply a pad of sealant type MD97389 to the surface of the water pipe that mates with the thermostat housing.

11. Moistened with water, install a new O-ring on the water outlet pipe, then press the thermostat housing against the latter. Screw in the mounting bolts and tighten them with the required force (22 Nm).

12. Connect the wiring to the sensors O2, ECT (and temperature meter), EGR, TPS and knock temperatures, as well as to the IAC drive motor and fuel injection injectors.

13. Connect the top radiator hose to the thermostat housing.

14. Connect the throttle cable to the throttle body.

15. Connect the engine oil pressure switch.

16. Connect the BB wires to the spark plugs.

17. After replacing the O-ring and mounting clamp, connect the fuel supply and return hoses.

18. Install the air intake sleeve. Connect the breather hose and replace the air cleaner cover.

19. Connect the vacuum hoses of the brake booster and crankcase ventilation system (PCV).

20. Fill the engine with fresh coolant (see chapter Settings and ongoing maintenance).

21. Connect the negative cable to the battery.

2.0L SOHC engines

Removing

1. Disconnect the negative cable from the battery.

If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

2. Empty the cooling system.

To avoid burns, proceed with the above work only after the system has completely cooled down! Do not allow antifreeze to come into contact with exposed areas of the body and painted surfaces of the car. Accidental splashes should be washed off immediately with plenty of water. Remember that antifreeze is a highly toxic liquid and getting it into the body, even in small quantities, is fraught with the most serious consequences (up to death). Never leave antifreeze stored in a loosely sealed container and clean up spilled coolant on the floor without delay. Remember that the sweet smell of antifreeze can attract the attention of children and animals. Consult any car service station about ways to dispose of used coolant. In many regions of the world, special points have been set up to receive various types of detention. Never drain old coolant down the drain and onto the ground!

3. Remove the air intake sleeve.

4. Disconnect the throttle cable and remove its support bracket.

5. Disconnect the fuel supply line (high pressure line), remove the O-ring.

6. Disconnect from a head of cylinders / the inlet pipeline the top radiator hose, a bypass hose of a cooling path and a heater hose.

7. Disconnect the vacuum line from the brake booster servo assembly.

8. Remove the fuel return line.

9. Mark and disconnect the vacuum hoses laid under the inlet pipeline. Also disconnect the PCV hose from the cylinder head cover.

10. Mark and disconnect the BB wires from the cover of the ignition distributor.

11. Mark and disconnect all other electrical wiring, including that connected to the distributor and fuel injection injectors.

Please note that some wires must be disconnected from the bulkhead of the engine compartment. After all connectors are undocked, unscrew the fasteners of the support brackets of the control wiring harness and take it aside.

12. Loosen the hose clamp for the air conditioning and power steering systems on the upper part of the bracket for the left suspension support of the power unit. Without disconnecting, take the hoses to the side.

13. Support the engine with a trolley jack (in order to distribute the load, lay a wooden block between the head of the jack and the engine sump). Cock the jack, completely unloading the supports of the power unit, but without raising the latter.

14. Turn out a through bolt of the left support of the unit (if necessary, vary the position of the jack in order to facilitate the removal of the bolt). After removing the through bolt, give the remaining fasteners and remove the support bracket from the engine.

15. Remove the cylinder head cover and its sealing gasket. Remove the half ring plug from the cylinder head.

16. Remove the upper timing belt cover. After turning the crankshaft clockwise, achieve the alignment of all the provided installation marks - the engine should be in the TDC position of the end of the compression stroke of the piston of the first cylinder.

17. Remove the mounting bolt and remove the camshaft gear, with the timing belt attached to it, - place the assembly on the lower section of the front cover.

Try to prevent the crankshaft from turning when the timing belt is removed!

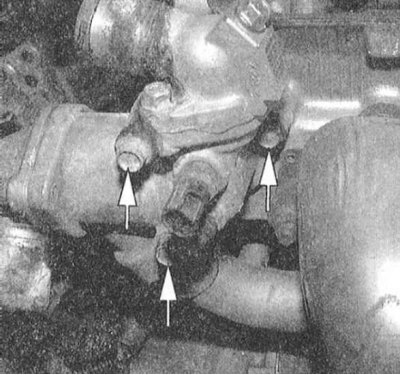

18. Give self-locking nuts and turn out a small bolt of fastening of a reception pipe of system of release of the fulfilled gases to a final collector. Separate the pipe from the manifold and remove the gasket.

19. Turn out bolts of fastening of a basic arm to the bottom part of the inlet pipeline.

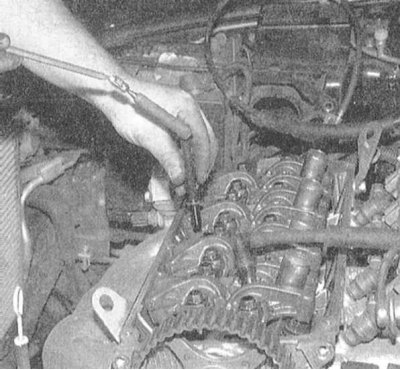

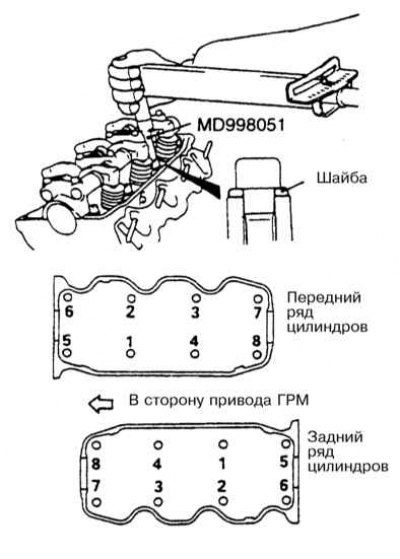

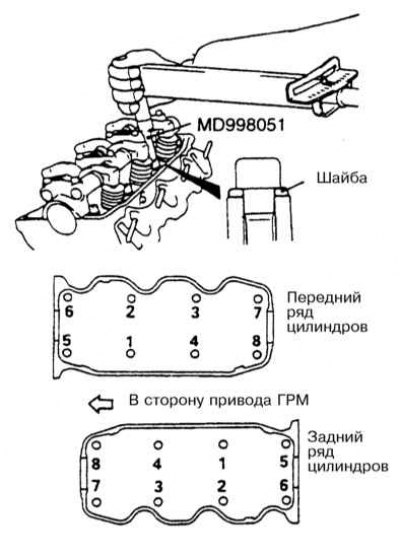

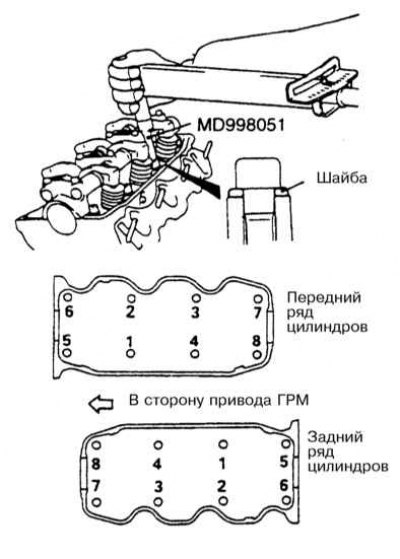

20. Acting in a strictly defined order, using a hex key (MV 998051-01) loosen the head bolts in two or three steps, then unscrew them by hand.

21. Shaking from side to side or tapping around the perimeter with a soft-faced hammer, separate the head from the block.

Never try to pry "stuck" head with a lever under the mating surface - if necessary, tap it around the perimeter with a hammer through a wooden block.

22. Remove the head assembly with the inlet pipeline / discharge chamber and exhaust manifold - if necessary, use the help of an assistant. Transfer the assembly to the workbench and lay it on a couple of wooden blocks. If necessary, dismantle the head. The description of procedure of cleaning and service of a head of cylinders is given below in the present Chapter.

23. Before installation, the head must be completely assembled on a workbench, which guarantees the correct installation and fastening of each of the installed components.

Installation

1. Thoroughly clean the mating surfaces of the head and cylinder block, completely removing traces of sealant and old gasket material from them. Finally, wipe the surfaces with a cloth soaked in acetone.

2. Place a new gasket on the block (identification mark up).

The gasket is laid dry, without the use of any sealants.

3. Carefully install the head on the block - try not to move the gasket.

4. Screw in the mounting bolts and, strictly in a certain order, in three stages, tighten them with the required force (see Specifications).

5. Install a support bracket on the inlet pipeline, screw in the fixing bolts and tighten them with the required force (22 Nm).

6. Having replaced a sealing lining, connect a reception pipe of system of release of the fulfilled gases to a final collector. Screw on new self-locking fixing nuts and tighten them to the required torque (35 Nm).

7. Make sure that the camshaft does not turn, then install the gear wheel assembly with the toothed belt on it. Screw in the fixing bolt and tighten it to 91 Nm.

8. Install the timing belt top cover. Screw in the mounting bolts and tighten them with the required force (11 Nm).

9. Lubricate the contact surfaces of the half-ring plug with sealant and install the latter in its regular place in the cylinder head. After replacing the gasket, install the cylinder head cover.

10. Install the powertrain mount bracket on the engine, tighten the fasteners (bolt pairs) with the required force (57 Nm).

11. Having worked with a jack, achieve the alignment of the holes in the support for the installation of the through bolt. Install the bolt and tighten the nuts securely.

12. Slowly lower the jack, fully transferring the weight of the unit to the support, then tighten the through bolt of the support with a force of 71 Nm. Tighten the small locknut to 36 Nm.

13. Install from above on the support bracket the mounting bracket for fastening the hoses of the air conditioning and power steering systems.

14. Get on the regular place a plait of electroconducting of management. Screw in and tighten the fixing bolts. Restore the original wiring connection, making sure it is routed correctly and the connector is secure.

15. Connect the spark plug wires to the ignition distributor cap.

16. Connect vacuum hoses and PCV hose.

17. Connect the fuel return line. Connect the vacuum hose to the brake booster servo assembly.

18. Install the heater hose, the water bypass pipe and the upper radiator hose, - make sure that the hoses are routed correctly (try to avoid twisting and excessive kinks) and the reliability of fastening them with their clamps.

19. After replacing the O-ring, connect the fuel supply line to the fuel line (before installation, the ring should be lightly lubricated with clean gasoline). Screw in the mounting bolts and tighten them with a force of not 6 Nm (not higher).

20. Connect and adjust the throttle cable.

21. Connect the air intake sleeve.

22. Fill the engine with fresh coolant (see chapter Settings and ongoing maintenance).

23. To minimize the risk of engine oil contamination, change the last (see chapter Settings and ongoing maintenance).

24. Connect the negative wire to the battery.

25. Start the engine and check it for signs of developing fluid leaks and vacuum losses. Check the electrical equipment for proper functioning, including the instrument panel and lighting fixtures.

26. If necessary, adjust the drive belts and the level of working fluids (coolant and engine oil).

Engines 1.6 or 2.0 L DOHC

Removing

1. Relieve pressure in the supply system.

2. Disconnect the negative cable from the battery.

If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

3. Empty the cooling system.

To avoid burns, proceed with the above work only after the system has completely cooled down! Do not allow antifreeze to come into contact with exposed areas of the body and painted surfaces of the car. Accidental splashes should be washed off immediately with plenty of water. Remember that antifreeze is a highly toxic liquid and getting it into the body, even in small quantities, is fraught with the most serious consequences (up to death). Never leave antifreeze stored in a loosely sealed container and clean up spilled coolant on the floor without delay. Remember that the sweet smell of antifreeze can attract the attention of children and animals. Consult any car service station about ways to dispose of used coolant. In many regions of the world, special points have been set up to receive various types of detention. Never drain old coolant down the drain and onto the ground!

4. Disconnect the gas cable from the throttle body.

On models equipped with speed control (tempostat) There are two throttle control cables.

5. Remove the air cleaner assembly with the air intake.

6. Disconnect the electrical wiring from the oxygen sensor (O2), coolant temperature sensor (EATING) and meter sensor/sensor-switch (on models with A/C) engine temperature.

7. Disconnect the electrical wiring from the idle speed stabilization system drive motor (ISC),throttle position sensor (TPS), crank angle sensor, knock sensor (turbocharged models) and EGR temperature sensor (california models), as well as from the fuel injection injectors, the power transistor and the noise suppression filter. Disconnect the ground strap and engine wiring harness.

8. Remove the top radiator hose and overflow tube.

9. Remove the central cover of the BB wiring protection and disconnect the wires from the spark plugs.

10. Disconnect (and seal immediately) fuel supply line.

11. Disconnect the small vacuum hose.

12. Remove the heater hose and water bypass hose.

13. Remove the PCV hose.

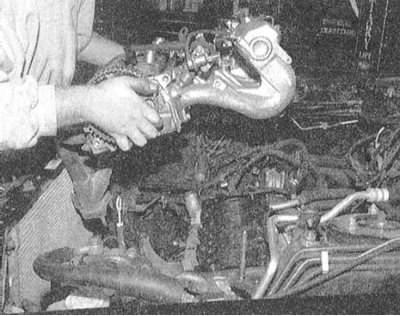

14. On models with a turbocharger remove vacuum hoses and lines of a water path, then turn out a hollow bolt of union connection and disconnect an oil pipeline from assembly of a turbocharger.

15. Disconnect (and seal immediately) fuel return line.

16. Disconnect the brake booster vacuum hose.

17. Remove the timing belt.

18. Remove the cylinder head cover and semicircular seal.

19. On models without turbocharging, release the self-locking nuts and disconnect the exhaust pipe from the exhaust manifold. Remove the seal.

20. On turbocharged models, remove the metal heat shield, then remove the bolts securing the turbocharger assembly to the exhaust manifold.

21. Acting strictly in a certain order, in three steps, loosen the head mounting bolts.

22. Remove the head and its sealing gasket from the cylinder block.

Installation

1. Thoroughly clean the mating surfaces of the head and cylinder block, completely removing traces of sealant and old gasket material from them. Finally, wipe the surfaces with a cloth soaked in acetone.

2. Check the condition of the head and evaluate the degree of its flatness. Compare measurement results with requirements Specifications. If necessary, give the head and / or block to the groove.

During turning, no more than 0.2 mm of metal should be removed from the surface of the head / block.

3. Place a new seal on the block (identification mark up).

The gasket is laid dry, without the use of any sealants. On appropriately equipped models, install the gasket and o-ring of the turbocharger assembly.

4. Carefully place the head on the block.

5. Screw in the mounting bolts and, strictly in a certain order, in three stages, tighten them with the required force (90÷100 Nm for a cold engine).

When checking the tightening force of the head fasteners on a hot engine, the reference value is 100÷110 Nm.

6. On turbocharged models, install the heat shield. On non-turbo models, replace the gasket and connect the downpipe to the exhaust manifold.

7. Lubricate the perimeter of the semicircular sealing insert and the lower edges of the semicircular sections of the new gasket from the front cover with sealant, then install the cylinder head cover.

8. Install the timing belt with related components.

9. Restore the original connection of communication and electrical lines. Connect and adjust cable (s) throttle actuator.

10. Install the center wiring protection cover.

11. After replacing the o-rings, connect both fuel lines.

12. Install the air cleaner assembly with the air intake. Connect the breather hose.

13. Change engine oil and oil filter.

14. Fill the engine with fresh coolant (see chapter Settings and ongoing maintenance).

15. Connect the negative cable to the battery.

16. Start the engine and warm it up to normal operating temperature (thermostat should open), then adjust the coolant level in the radiator accordingly.

17. Check the idle speed and ignition timing settings. Make appropriate adjustments if necessary.

18. After the final cooling of the engine, check the coolant level again.

Engines 2.4 l

Removing

1. Relieve pressure in the supply system.

2. Disconnect the negative cable from the battery.

If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

3. Remove the air cleaner assembly with the air intake.

4. Empty the cooling system.

To avoid burns, proceed with the above work only after the system has completely cooled down! Do not allow antifreeze to come into contact with exposed areas of the body and painted surfaces of the car. Accidental splashes should be washed off immediately with plenty of water. Remember that antifreeze is a highly toxic liquid and getting it into the body, even in small quantities, is fraught with the most serious consequences (up to death). Never leave antifreeze stored in a loosely sealed container and clean up spilled coolant on the floor without delay. Remember that the sweet smell of antifreeze can attract the attention of children and animals. Consult any car service station about ways to dispose of used coolant. In many regions of the world, special points have been set up to receive various types of detention. Never drain old coolant down the drain and onto the ground!

5. Disconnect the throttle cable. Loosen the support brackets and move the cable assembly aside.

6. Remove the breather tube.

7. Mark and disconnect vacuum lines from the throttle case.

8. Disconnect (and seal immediately) fuel supply line.

9. Disconnect the electrical wiring from the compressor of the air conditioning system, the pressure switch of the power steering system (power steering), oxygen sensor (O2), coolant temperature sensor (ECT) and a sensor of the engine temperature meter, an absolute pressure sensor in the pipeline (MAP), intake air temperature sensor (IAT),throttle position sensor (TPS), camshaft position sensor (CMP), EGR solenoid valve, idle speed stabilization device drive motor (IAC), fuel injection injectors and ignition coils.

10. Remove the central cover of the BB wiring protection and disconnect the spark plug wires.

11. Disconnect the hoses of the cooling path and unbolt the thermostat housing from the engine.

12. Remove the upper timing belt cover.

13. Achieve the correct alignment of all provided alignment marks.

14. Fasten the gas distribution belt to the camshaft gear with a wire, then remove the latter.

15. Remove a cover of a head of cylinders and take a semicircular sealing insert.

16. Disconnect the support bracket from the intake manifold assembly.

17. Give self-locking nuts and disconnect a reception pipe of system of release of the fulfilled gases from a final collector. Remove the seal.

18. Acting strictly in a certain order, in three steps, loosen the head mounting bolts.

It is convenient to remove the head bolts using a magnet.

19. Remove the head and its sealing gasket from the cylinder block.

Installation

1. Thoroughly clean the mating surfaces of the head and cylinder block, completely removing traces of sealant and old gasket material from them. Finally, wipe the surfaces with a cloth soaked in acetone.

2. Place a new gasket on the block (identification mark up).

The gasket is laid dry, without the use of any sealants.

3. Evaluate the condition of the mounting bolts, replace the bolts whose length exceeds 99.4 mm.

4. Before installation, lightly lubricate the threaded part of the bolts with liquid machine oil. Put washers under the heads (chamfer out).

5. Carefully place the head on the block.

6. Screw in the mounting bolts and, strictly in a certain order, in three stages, tighten them with the required force (78 Nm - see Specifications)

7. Replace a sealing lining and connect a reception pipe to a final collector. Tighten fasteners to the required torque (44 Nm).

8. Install the thermostat housing. Screw in the three fixing bolts and tighten them to the required torque (24 Nm).

9. Connect to the thermostat hoses of a cooling path.

10. Lubricate the perimeter of the semicircular sealing insert and the lower edges of the semicircular sections of the new gasket from the front cover with sealant, then install the cylinder head cover.

11. Install the timing belt with related components.

Do not forget to untie the belt from the camshaft gear.

12. Restore the original connection of communication and electrical lines. Connect and adjust cable (s) throttle actuator.

13. Install the timing belt top cover.

14. Install the support bracket on the inlet pipeline, screw in the fixing bolts and tighten them with the required force (30 Nm).

15. Connect the wiring to the O2, ECT, MAP, IAT, TPS and CMP sensors, as well as to the A/C compressor, power steering pressure switch, IAC drive motor, injection injectors, ignition coil and EGR solenoid valve.

16. Connect the BB wiring and install the protective cover of the spark plug wires.

17. After replacing the o-rings, connect the fuel lines.

18. Install the air cleaner with the air intake. Connect the breather hose.

19. Fill the engine with fresh coolant (see chapter Settings and ongoing maintenance).

20. Connect the negative wire to the battery.

3.0L DOHC engines

Removing

1. Relieve pressure in the supply system.

2. Disconnect the negative cable from the battery.

If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

3. Empty the cooling system.

To avoid burns, proceed with the above work only after the system has completely cooled down! Do not allow antifreeze to come into contact with exposed areas of the body and painted surfaces of the car. Accidental splashes should be washed off immediately with plenty of water. Remember that antifreeze is a highly toxic liquid and getting it into the body, even in small quantities, is fraught with the most serious consequences (up to death). Never leave antifreeze stored in a loosely sealed container and clean up spilled coolant on the floor without delay. Remember that the sweet smell of antifreeze can attract the attention of children and animals. Consult any car service station about ways to dispose of used coolant. In many regions of the world, special points have been set up to receive various types of detention. Never drain old coolant down the drain and onto the ground!

4. Remove the air intake sleeves.

5. Remove the intake manifold assembly with the pressure chamber (see Section Removal and installation of the inlet pipeline).

6. Remove the exhaust manifold (see Section Removal and installation of a final collector).

7. Remove the timing belt (see Section Removing and installing timing cover and timing belt).

8. Remove the breather tube.

9. Remove the central cover of the BB wiring protection and disconnect the wires from the spark plugs.

10. Remove the cylinder head covers.

11. Remove the intake camshaft gear.

12. Remove the rear timing belt cover.

13. Remove the ignition coil.

14. Disconnect the hoses and remove the thermostat housing.

15. Disconnect the water inlet from the front head.

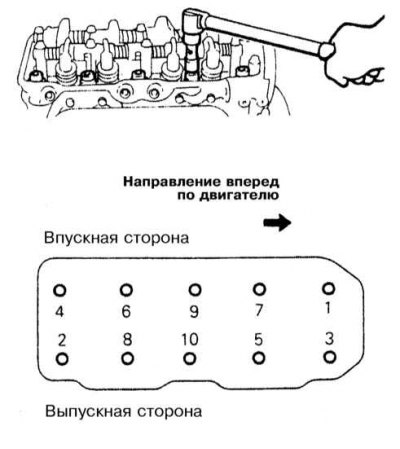

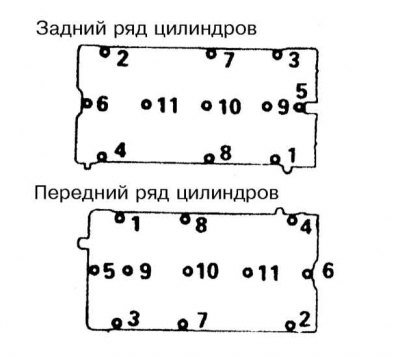

16. Acting in the reverse order shown in the illustration, loosen the cylinder head bolts in three steps.

17. Remove the head and its seal.

Installation

1. Thoroughly clean the mating surfaces of the heads and cylinder block, completely removing traces of sealant and old gasket material from them. Finally, wipe the surfaces with a cloth soaked in acetone.

2. Place a new gasket on the block (identification mark up).

The gasket is laid dry, without the use of any sealants.

3. Carefully place the head on the block.

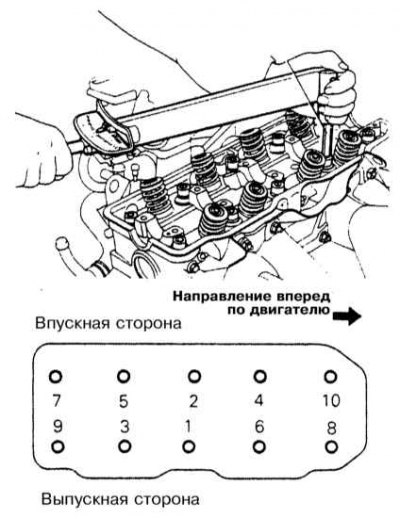

4. Putting washers (chamfer up), screw in the fixing bolts and, strictly in a certain order, in three steps, evenly tighten them with the required force (105÷115 Nm).

5. After replacing the O-ring, connect the water inlet to the head. Screw in the mounting bolts and tighten them with the required force (12÷15 Nm).

6. After replacing the gaskets, install the thermostat housing in its original place. Screw in the fixing bolts and tighten them with a force of 17÷20 Nm.

7. Connect the hoses of the cooling path to the thermostat and securely fasten them with new clamps.

8. Install the ignition coil by tightening the bolts of its fastening with the required force (10 Nm).

9. Install the rear timing cover, - the required tightening torque of the cover bolts is 24 Nm.

10. Install the intake camshaft gears.

Screw in the fixing bolt and tighten it to the required torque (90 Nm).

11. Lubricate the lower edges of the cylinder head cover with sealant. Screw in the mounting bolts and, acting strictly in a certain order, evenly tighten them with the required force (5÷6 Nm).

12. Connect the spark plug wires and install the central cover for the protection of the BB electrical wiring. Screw in the mounting bolts and tighten them with the required force (3 Nm).

13. Connect the breather hose.

14. Install the timing belt (see Section Removing and installing timing cover and timing belt).

15. Install the exhaust manifold assembly (see Section Removal and installation of a final collector).

16. After replacing the gaskets, install the intake manifold assembly with the pressure chamber (see Section Removal and installation of the inlet pipeline).

17. Install the air intake sleeves.

18. Change engine oil and oil filter (see chapter Settings and ongoing maintenance).

19. Fill the engine with fresh coolant (see chapter Settings and ongoing maintenance).

20. Connect the negative wire to the battery.

21. Adjust the throttle cable.

22. Start the engine, warm it up to normal operating temperature and check the idle speed and ignition timing settings. Make appropriate adjustments if necessary.

23. After the final cooling of the engine, check the coolant level again.

3.0L SOHC engines

Removing

1. Relieve pressure in the supply system.

2. Disconnect the negative cable from the battery.

If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

3. Empty the cooling system.

To avoid burns, proceed with the above work only after the system has completely cooled down! Do not allow antifreeze to come into contact with exposed areas of the body and painted surfaces of the car. Accidental splashes should be washed off immediately with plenty of water. Remember that antifreeze is a highly toxic liquid and getting it into the body, even in small quantities, is fraught with the most serious consequences (up to death). Never leave antifreeze stored in a loosely sealed container and clean up spilled coolant on the floor without delay. Remember that the sweet smell of antifreeze can attract the attention of children and animals. Consult any car service station about ways to dispose of used coolant. In many regions of the world, special points have been set up to receive various types of detention. Never drain old coolant down the drain and onto the ground!

4. Remove the air intake sleeve.

5. Remove the intake manifold assembly with the pressure chamber (see Section Removal and installation of the inlet pipeline).

6. Remove the timing belt (see Section Removing and installing timing cover and timing belt).

7. Remove the camshaft gears and the timing belt rear cover.

8. Remove the steering pump support bracket.

When dismantling the rear cylinder head, remove the alternator support bracket accordingly.

9. Disconnect the water inlet.

10. Remove the purge tube assembly.

11. Remove the cylinder head cover.

12. Acting in the reverse order shown in the illustration, loosen the cylinder head bolts in three steps.

13. Remove the head and its seal.

Installation

1. Thoroughly clean the mating surfaces of the heads and cylinder block, completely removing traces of sealant and old gasket material from them. Finally, wipe the surfaces with a cloth soaked in acetone.

2. Place a new gasket on the block (identification mark up).

The gasket is laid dry, without the use of any sealants.

3. Carefully place the head on the block.

4. Putting washers (chamfer up), screw in the fixing bolts and, strictly in a certain order, in three steps, evenly tighten them with the required force (105÷115 Nm).

5. Lubricate the lower edges of the semicircular sections with sealant, install the cylinder head cover on the block. Screw in the fixing bolts and evenly tighten them to the required torque (9 Nm).

6. Install the purge tube assembly.

7. Connect the water inlet. Install the generator and/or steering pump support brackets.

8. Install the timing belt rear cover and camshaft gears. Screw in the gear wheel mounting bolts and tighten them to the required torque (90 Nm).

9. Install timing belt (see Section Removing and installing timing cover and timing belt).

10. After replacing the gaskets, install the intake manifold assembly with the pressure chamber (see Section Removal and installation of the inlet pipeline).

11. Install the exhaust manifold (see Section Removal and installation of a final collector).

12. Install the air intake sleeve.

13. Fill the engine with fresh coolant (see chapter Settings and ongoing maintenance).

14. Connect the negative cable to the battery.

15. Start the engine, warm it up to normal operating temperature and check the idle speed and ignition timing settings. Make appropriate adjustments if necessary.

16. After the final cooling of the engine, check the coolant level again.

Engines 3.5 l

Removing

1. Disconnect the negative cable from the battery.

If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

2. Empty the cooling system.

To avoid burns, proceed with the above work only after the system has completely cooled down! Do not allow antifreeze to come into contact with exposed areas of the body and painted surfaces of the car. Accidental splashes should be washed off immediately with plenty of water. Remember that antifreeze is a highly toxic liquid and getting it into the body, even in small quantities, is fraught with the most serious consequences (up to death). Never leave antifreeze stored in a loosely sealed container and clean up spilled coolant on the floor without delay. Remember that the sweet smell of antifreeze can attract the attention of children and animals. Consult any car service station about ways to dispose of used coolant. In many regions of the world, special points have been set up to receive various types of detention. Never drain old coolant down the drain and onto the ground!

3. Remove the timing belt (see Section Removing and installing timing cover and timing belt).

4. Remove the inlet pipeline and a final collector.

5. Remove spark plug wires.

6. Remove the cylinder head covers.

7. Remove the center section of the rear timing belt cover.

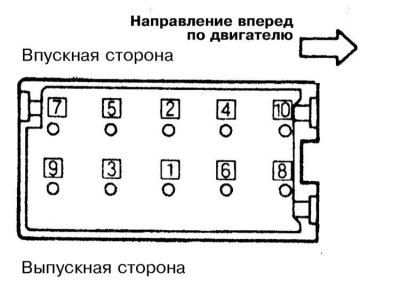

8. Loosen the cylinder head bolts in three steps.

9. Remove the head and its seal.

Installation

1. Thoroughly clean the mating surfaces of the heads and cylinder block, completely removing traces of sealant and old gasket material from them. Finally, wipe the surfaces with a cloth soaked in acetone.

2. After replacing the gasket, carefully place the head on the block.

3. In three steps, evenly tighten the head bolts to the required torque (103÷113 Nm).

4. Install the center section of the rear timing belt cover.

5. After replacing the gaskets, install the cylinder head covers. Screw in the mounting bolts and tighten them with the required force (3÷4 Nm).

6. Connect spark plug wires.

7. Install the intake piping and exhaust manifold.

8. Install timing belt (see Section Removing and installing timing cover and timing belt).

9. Install all other components removed for access.

10. Fill the engine with fresh coolant (see chapter Settings and ongoing maintenance).

11. Connect the negative cable to the battery.