Note. Some special maintenance procedures that require additional fluid level checks are also described below. Check under the vehicle regularly for signs of fluid leaks.

Checking the levels of the main working fluids (engine oil, coolant, windshield washer fluid, battery electrolyte, power steering fluid) should be carried out on a regular basis, at least once a month or every 5000 km. The rest - in accordance with the maintenance schedule (see Section Mitsubishi Galant/Mirage/Diamante Routine Maintenance Schedule).

Various fluids play the role of working fluids in lubrication, cooling, braking, clutch, heating and air conditioning systems, glass washing, etc. Due to the fact that all fluids are subject to thinning and exhaustion over time, and also gradually become contaminated during the normal operation of systems, it is necessary to periodically replace them completely. Please refer to the list of fluids recommended for use in your vehicle before attempting to level or replace.

Note. When checking fluid levels, the car must be parked on a flat horizontal area, if possible with a hard surface.

Engine oil

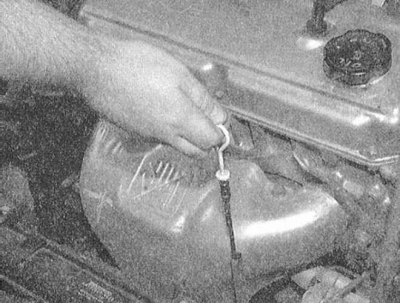

1. Checking the level of impellent oil is carried out using a dipstick threaded into the guide tube and lowered into the engine to the lowest point of its oil pan. The location of the measuring probe is shown in the illustrations showing the placement of components in the engine compartment of the car and placed at the beginning of this Chapter.

2. Checking the oil level should be done before the first ride of the day, or about 15 minutes after the engine has stopped. If the check is performed immediately after the engine is turned off, the results will not adequately reflect the situation, as part of the oil will be distributed to the internal galleries and engine components.

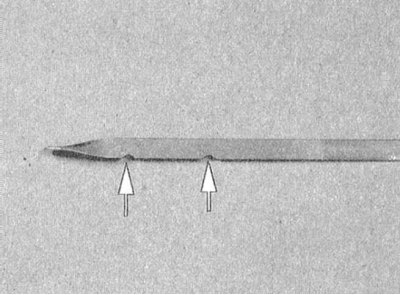

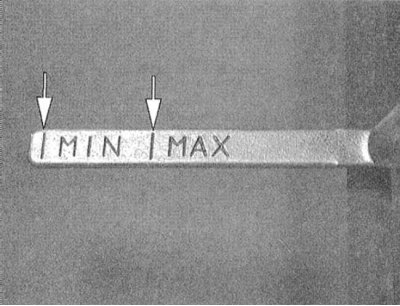

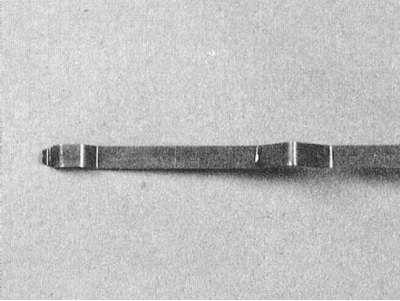

3. Remove the dipstick from the guide tube and dry its blade with a clean cloth or paper towel. Insert the dipstick back into the tube until it stops, then remove it again. After examining the probe blade, estimate the size of the area wetted with oil. The oil level should be between the upper and lower marks on the dipstick blade. If necessary, top up the engine with the appropriate amount of oil of the required grade.

|  |

4. To raise the level from the bottom (MIN) marks on the dipstick to the top (MAX) a little less than one liter of oil is required. Lowering the level beyond the lower limit of the permissible range leads to the development of engine oil starvation, which is fraught with serious mechanical damage to the latter. Try also not to overfill the oil above the upper mark, as this can lead to throwing spark plugs or failure of the power unit seals as a result of excessive pressure buildup.

5. To fill the engine with oil, remove the threaded filler cap. Use a funnel or an oil can with a long spout to avoid splashing oil when filling it into the engine. After filling in oil, screw on and firmly tighten the filler cap, then start the engine and carefully inspect the drain plug and the surface of the oil filter mating with the block for signs of leakage. Stop the engine, wait about 15 minutes for the oil to drain into the sump, then check the level again.

6. Checking the engine oil level is an important preventative engine maintenance procedure. A constantly low level indicates the presence of oil leaks as a result of failed oil seals, damaged seals, worn piston rings or valve guides. If the oil resembles milk in color or consistency, or there are drops of water in it, this indicates a possible damage to the cylinder head gasket, or the formation of cracks in the body of the head (OK) or block. The check must be made without delay. When measuring the oil level, always also check its condition. Using your thumb and forefinger, remove traces of oil from the dipstick blade - if there are small metal particles in it, the oil must be replaced (see Section Changing the engine oil and oil filter).

Engine coolant

Attention! Do not allow antifreeze to come into contact with exposed areas of the body and painted surfaces of the car. Wash off accidental splashes with plenty of water without delay. Remember that antifreeze is a highly toxic liquid and getting it into the body, even in small quantities, is fraught with the most serious consequences, even death. Never leave antifreeze stored in a loosely closed container, immediately collect spilled coolant on the floor. Remember that the sweet smell of antifreeze can attract the attention of children and animals. Consult your local authorities for disposal of used coolant, - in many regions of the world there are special points for receiving various kinds of waste. Never drain old coolant down the drain and onto the ground!

Note. Recently, non-toxic grades of antifreeze have been developed, however, they must also be disposed of in an organized manner.

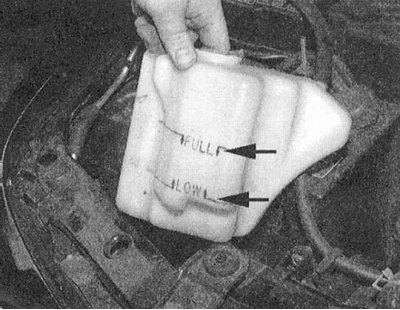

1. All models of vehicles described in this manual are equipped with an overpressure compensation type cooling system. Made of translucent plastic, the expansion tank of the cooling system is located in the front corner of the engine compartment close to the battery and is connected by an overflow hose to the base of the radiator filler neck. When the engine warms up, the coolant expands, and its excess flows through the valve mounted in the radiator filler cap into the expansion tank. As it cools, the liquid returns through the hose back to the radiator, which allows you to constantly maintain its normal level in the system.

Attention! Never remove the cap from the filler neck of the radiator/expansion tank when the engine is hot!

2. The coolant level in the expansion tank is checked on a regular basis and must be maintained between the FULL and LOW marks on the stack of the translucent plastic reservoir. It should be remembered that the level of the coolant depends on its temperature, therefore, in a cold state, it should be only slightly above the lower (LOW), and after warming up the engine - rise to the FULL mark. If necessary, make the appropriate adjustment by adding the required amount of fresh mix to the reservoir.

Attention! Use only the correct mixture of ethylene glycol and distilled water to correct the fluid level (about 50/50). Remember that the frequent use of plain water for this purpose leads to a gradual dilution of the antifreeze and the loss of frost resistance and anti-corrosion properties of the mixture. You should also not abuse various types of additives.

3. A constant drop in the coolant level usually indicates the development of leaks in the system. Check the radiator, connecting hoses, filler cap, drain plugs and water pump housing for signs of leakage. If no signs of leaks can be detected, a pressure test of the radiator cap should be carried out in a car service workshop.

Attention! Never remove the cap from the radiator/expansion tank when the engine is hot!

4. If it is necessary to remove the radiator cap, wait for the engine to cool completely, then wrap the neck with a thick layer of rags and slowly unscrew the cap to the first stop. If this produces steam, let the engine cool down a little more, only then remove the cover completely.

5. In addition to the level, always also check the condition of the coolant - it should be relatively clear. If the coolant is rust reddish brown, the cooling system must be emptied, flushed and filled with a fresh mixture of antifreeze and water. Even if the fluid does not change externally, the corrosion inhibitors it contains will wear out over time, so the coolant must be changed regularly in accordance with the vehicle's routine maintenance schedule (see Section Mitsubishi Galant/Mirage/Diamante Routine Maintenance Schedule).

6. Avoid getting antifreeze on exposed skin or painted surfaces of body components. Accidental splashes should be washed off immediately with plenty of water.

Windshield washer fluid

Windshield washer fluid is poured into a special plastic reservoir located in the front corner of the car's engine compartment, opposite the corner where the battery and expansion tank of the cooling system are located. In temperate regions, clean water can be used as a glass washer fluid, but the tank should not be more than 2/3 full to compensate for the expansion of the water when it freezes during frosts. When operating the vehicle in harsh climates, use only proprietary windshield wipers that provide adequate reduction in the fluid's freezing point. To avoid freezing of the glass when washing in cold weather, preheat it by blowing air passed through the heater heat exchanger

Attention! Mixing rules are usually printed on the container label. In no case do not use antifreeze used in the cooling system to add glass washer fluid - the latter is aggressive towards the paintwork of body panels!

Battery electrolyte

The vehicles covered in this manual are equipped with a maintenance-free, sealed-type battery with only vent holes in the casing. The battery case can be made of translucent plastic - in this case, the electrolyte level in its banks can be monitored in order to obtain indirect information about the correct functioning of the charge system and the current state of the battery. If during the operation of the vehicle the battery for any reason was replaced with a conventional (serviced type), you should check the electrolyte level in its banks from time to time, for which it is necessary to remove the upper control / filler plugs. Particular attention should be paid to the electrolyte level in the warm season. Only distilled water should be used to correct the electrolyte level.

Hydraulic fluid brake and clutch

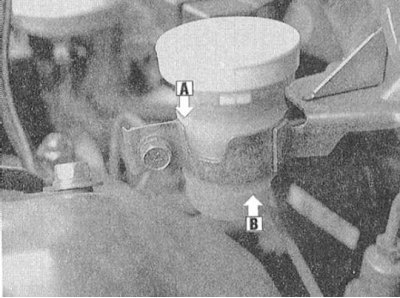

1. Master cylinder (GTZ) mounted on the servo block of the vacuum brake booster. The hydraulic clutch cylinder is used on models with manual transmission and is mounted on the rear bulkhead of the engine compartment next to the GTZ (the location of the reservoirs of both cylinders is shown in the accompanying illustrations explaining the location of the components in the engine compartments of the models under consideration at the beginning of this Chapter).

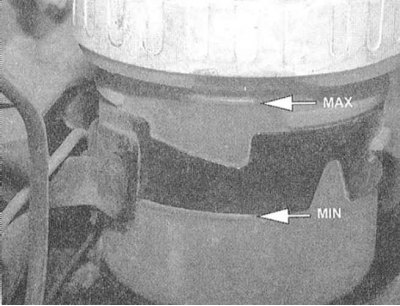

2. The fluid level inside the GTZ tanks and the clutch drive is clearly visible through the translucent walls of the latter and must be maintained between the MIN and MAX marks, not reaching the top by 8 ÷ 9 mm.

|  |

3. If it is necessary to adjust the fluid level, carefully wipe the cap of the respective reservoir and the area around it with a clean rag to prevent dirt from entering the hydraulic system.

4. When pouring liquid into the tank, make sure that it does not splash onto the surrounding painted surfaces of the body elements. Add only the correct grade of fluid to each system (see Specifications at the beginning of this chapter), - the mixing of two liquids of different grades is in no case unacceptable and may lead to failure of the corresponding system!

Attention! Brake fluid is highly chemically aggressive - do not let it get into your eyes and onto painted surfaces of body panels! Do not use hydraulic fluid that has stood for more than one year or has been stored in a loosely closed container to add to the system. Remember that brake fluid is very hygroscopic, ie. has the ability to absorb moisture from the air, as a result of which the effectiveness of the brake system can be dangerously reduced!

5. During the level adjustment step, you should also carefully check the condition of the liquid and the internal walls of the tank. If dirt deposits, solid foreign particles or water droplets are detected, the system must be emptied and filled with fresh hydraulic fluid (see chapters Clutch and transmission line and Brake system).

6. After the reservoir is filled to the required level, fit the lid tightly onto it.

7. Remember that the level of hydraulic fluid in the GTZ reservoir gradually drops as the friction linings of the brake pads actuate, but this decrease is always very small. If the fluid has to be topped up too often, therefore, there is a leak in the system, the source of which must be identified without delay, and the cause eliminated - carefully inspect all brake lines and their union connections, including calipers, wheel cylinders and vacuum booster servo (see Section Check of serviceability of functioning of the vacuum amplifier of brakes). A drop in the fluid level in the clutch hydraulic reservoir indicates the development of leaks in the tract, including the slave cylinder (see chapter Clutch and transmission line).

8. If, during the check of the fluid level in the main cylinders, the fact that its reservoir is almost empty is revealed, the corresponding system must be completely pumped (see chapter Clutch and transmission line or Brake system).

Power steering fluid

1. The power steering fluid reservoir is located in the front corner of the engine compartment behind the washer fluid reservoir (see the accompanying illustrations explaining the location of the components in the engine compartments of the models under consideration at the beginning of this Chapter).

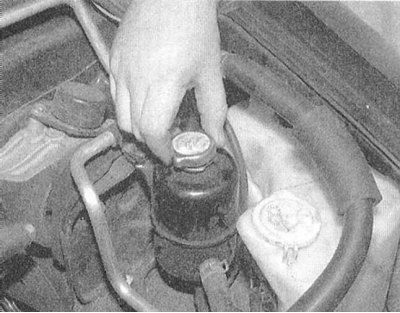

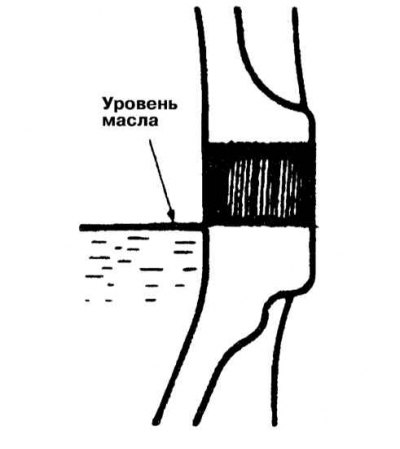

2. The tank cover is equipped with a built-in dipstick. The verification procedure is standard for all measurements with probes.

|  |

3. Try not to allow the liquid level to go beyond the lower limit of the allowable range.

4. If necessary, make appropriate level adjustments by topping up the reservoir neck with the correct grade of hydraulic fluid.

5. If the need to adjust the fluid level occurs regularly and frequently, check for signs of leakage of the steering pump, rack and pinion housing, as well as all connecting lines of the hydraulic path of the system and their union connections.

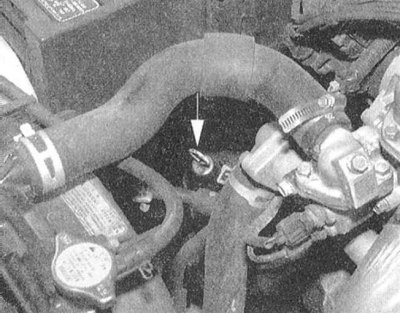

Gearbox oil

1. The gearbox housing is not equipped with a dipstick. Jack up the car and place it on jack stands. The level of transmission oil in the gearbox is checked by turning out the control / filler plug from the side wall of the gearbox housing.). Locate the plug and carefully wipe the box crankcase surrounding it with a clean rag. Using a spanner or socket wrench, unscrew the plug - the gear oil level in the crankcase should reach the lower cut of the control / filler hole, otherwise it is necessary to make an appropriate adjustment. If the vehicle is raised off the ground to provide access to the gearbox housing, make sure that the props are securely fastened before climbing under it.

Attention! The car must be installed strictly horizontally!

|  |

2. Using a funnel with a suitable adapter nozzle, pour the required amount of fresh gear oil into the manual transmission case. Continue adding oil until oil overflows from the bottom edge of the filler/inspection hole.

3. Replace the thoroughly wiped plug and tighten firmly. Carry out a short road test of the vehicle, after which make sure that there are no signs of the development of oil leaks through the plug.

ATF

1. Correct ATF level is one of the critical performance parameters for AT equipped models. An excessive drop in the ATF level can cause the rotation converter to slip, while an excessive amount of fluid leads to its foaming, leakage and is fraught with transmission failure.

2. Checking the ATF level should be done with the transmission warmed up to normal operating temperature (15÷20 km run, 72÷80°С).

Attention! Do not check the ATF level immediately after driving the vehicle at high speeds, in urban conditions in hot weather, or after towing a trailer - let the fluid cool down for about 30 minutes beforehand!

3. Park the vehicle on a level, hard paved area and apply the parking brake firmly. If the engine is cold, start it and warm it up to normal operating temperature at idle. With the engine running, depress the foot brake pedal and alternately move the AT selector lever through all positions, finally returning it to the position "R".

4. With the engine running, remove the dipstick from the guide tube. Use your fingers to remove traces of ATF from the dipstick blade and evaluate its condition by touch.

5. Wipe the blade thoroughly with a clean cloth and insert the probe back into the guide tube, making sure the cap is firmly seated on the mouth.

6. Remove the dipstick from the throat again and determine the ATF level in the transmission housing by the length of the wetted area of the blade. If necessary, make the appropriate adjustment by adding the required grade of fluid to the transmission through a funnel - pour ATF directly into the neck of the dipstick guide tube.

7. To raise the ATF level from the lower limit of the dipstick operating range to the upper one, about 0.6 l of liquid is required - add ATF in small portions in several steps, each time checking the level.

8. Simultaneously with the level, the condition of the ATF should also be checked. If the fluid wetting the tip of the dipstick blade is dark red-brown or smells of burning, the ATF should be replaced (see Section Replacing ATF automatic transmission and final drive differential, checking the condition and servicing the AT filter). If you are unsure about the correct assessment of the condition of the transmission fluid, compare it by color and smell with fresh ATF.

Checking the lubricant level in the transfer case (only all-wheel drive Galant)

1. Park the vehicle on a level, level surface, if possible paved. Set the parking brake, on models with AT, move the selector lever to the position "R".

2. Before proceeding with the check, inspect the transfer case housing for signs of leak development. The lubricant level in the transfer case on all-wheel drive models should reach the lower cut of the control / filler hole on the back of its crankcase. Insert your finger into the hole to check. In parallel, evaluate the condition of the oil poured into the box by touch.

3. If necessary, make the appropriate adjustment by adding the required amount of oil through the filler hole - use a funnel or hand pump.

4. Track reliability of a tightening of a stopper.

Rear axle differential lubrication (only all-wheel drive Galant)

1. Park the vehicle on a level, level surface, if possible paved. Set the parking brake, on models with AT, move the selector lever to the position "R".

2. The lubricant level in the differential must also reach the lower cut of the control / filler hole. Insert your finger into the hole to check. In parallel, evaluate the condition of the oil poured into the box by touch.

3. If necessary, make the appropriate adjustment by adding the required amount of oil through the filler hole - use a funnel or hand pump.

4. Track reliability of a tightening of a stopper.