VV wiring

External State Check

1. Checking the condition of the BB wires should be done every time the spark plugs are replaced.

2. The check begins with an external inspection of the insulation of the wires with the engine running. Drive the car into a dark, well-ventilated area, start the engine and check for sparking on the wires. Sparking is a sign of insulation breakdown. Avoid touching moving components in the engine compartment. Make the necessary notes on the replacement of defective wires, then let the engine cool down and proceed to check the condition of the ignition distributor cap and runner.

3. Checking the spark plug wires is carried out one by one in order to avoid violating the order of their connection during assembly. Usually, there is a corresponding marking on the insulation of branded wires. If there is none, apply it yourself with tape and a marker.

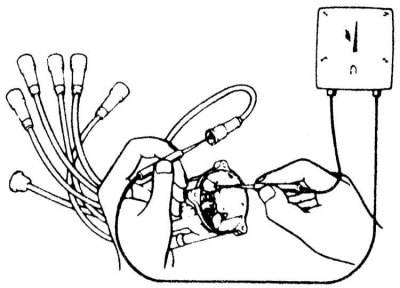

4. Disconnect the BB wire from the spark plug (it is best to use a special tool). In no case do not pull on the wire itself, only on its tip.

On models of recent years of production, in order to gain access to the spark plugs, it is necessary to remove the top cover from the cylinder head cover.

5. Inspect the inside walls of the tip. Corrosion usually appears as a brittle, crusty, white deposit. In case of severe oxidation, replace the wire.

6. Pull the tip back over the shank of your spark plug, making sure it fits snugly. If necessary, remove the ferrule again and fold the terminals inside the rubber boot accordingly.

7. With a clean rag, wipe the wire along its entire length, completely removing traces of dirt and grease from the surface of the insulation. Inspect the wire insulation for cracks, burn marks, or other damage. Try not to bend the wire at sharp angles to avoid breaking the integrity of the conductor cores inside the insulation.

8. Disconnect a wire from the distributor, - again pull only for a tip, but not for a wire. Check the tip for signs of corrosion, evaluate its fit on the terminal. Reconnect the wire to the distributor.

9. In a similar manner, check the condition of all remaining spark plug wires one by one. Make sure that they are securely connected to the spark plugs and distributor terminals.

10. If it is necessary to replace the BB wires (see below) make sure that the replacement wires correspond in size to the parameters of your car engine. In Mitsubishi branded car accessory stores and service centers, you can always purchase ready-to-use sets of BB wires, cut to length and equipped with ferrules. Remove and replace wires one at a time to avoid misfiring.

Resistive resistance measurement

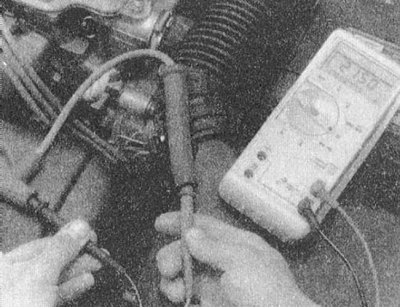

1. Checking the resistive resistance of the BB wiring is done using an ohmmeter. Excessive spark plug wire resistivity causes misfires and engine start failures in high atmospheric humidity conditions.

2. The measurement is made for each wire separately. An ohmmeter is connected between the end terminals of the wire. A description of the procedure for removing and installing the BB wires / ignition distributor cover is given below.

|  |

3. After taking readings, compare the obtained results with the requirements of the Specifications. The nominal value is 1333÷2000 Ohm/dm. Wires with increased specific resistive resistance must be replaced.

Removal and installation

1. Remove the air cleaner intake sleeve.

2. At a corresponding complete set of the car remove the central cover from a cover of a head of cylinders.

3. Mark the BB wiring with adhesive tape, try to remember the route of laying each of the wires.

4. Starting with the longest, disconnect the BB wires from the spark plugs and from the coil modules/distributor cover one by one.

5. When installing in place of the old electrical wiring, carefully follow the order of connecting the wires (see marking applied before removal).

6. New wires must exactly match those removed from the car in size.

7. Lubricate the protective covers of the lugs of the BB wires with dielectric grease and put the lugs on the terminals of the ignition modules / distributor cover. Check that the tips are secure.

8. Having laid each of the spark plug wires in accordance with the diagram drawn up during the dismantling process, connect them to the corresponding spark plugs (start by laying the longest wire and work in descending order).

9. Finally, reinstall the air intake sleeve.

Cover and distributor slider

1. Disconnect the negative cable from the battery.

If the stereo system installed in the car is equipped with a security code, before disconnecting the battery, make sure that you have the correct combination to activate the audio system!

2. Mark and disconnect the electrical wiring from the cover of the BB distributor (see above).

3. Turn out fixing screws / release clamps and remove a cover from the distributor case.

4. Mark the installation position of the slider and remove it from the distributor shaft.

5. It is good practice to replace the distributor cap and runner, regardless of their condition, every time new BB wires are installed. When using old components, carefully clean the contact surfaces of their terminals and measure the resistance between the wires and the cover (see above). Replace cover and/or wires if necessary.

6. If replacing the distributor cover and slider is not included in the work plan, thoroughly wash the removed components with soapy water and dry them (using compressed air if possible). Make sure that after wiping the components with a rag, there are no sticky and stuck fibers and lint particles left on them.

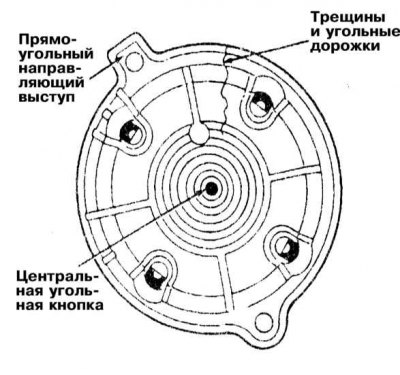

7. Carefully inspect the distributor cover for cracks, chipped terminal lining, burn marks, carbon tracks and other defects; Evaluate the condition of the central button of the contact electrodes/terminals.

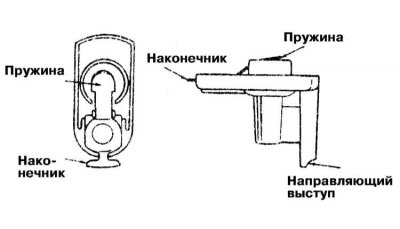

8. Assess the condition of the working tip and slider spring.

9. Install the components in the reverse order of their dismantling. When installing a new distributor cap, transfer the wires from the old BB to it, connecting them in a strictly defined order to avoid disturbing the ignition order - try not to disconnect all the wires at the same time, transfer them one by one.

The firing order is specified in Specifications at the beginning of this chapter. On most models, the protective tab (lining) the terminals for connecting the wire of the spark plug of the first cylinder on the distributor cap are marked accordingly.