General information

The ignition timing is the angle through which the crankshaft rotates between the moments of ignition of the mixture in each successive cylinder. The measurement is made relative to the TDC of the end of the compression stroke of the corresponding piston, the result is expressed in angles before or after TDC

Ideally, the ignition of the air-fuel mixture in the combustion chamber of the cylinder should be carried out at the moment the piston passes the TDC position of the end of the compression stroke. In this case, the explosively increasing pressure in the cylinder will push the piston down, thereby causing the engine crankshaft to rotate. Due to the fact that sparking between the electrodes of the candle / ignition of the mixture takes some time (fractions of a second), ignition must be carried out a little before the piston reaches the TDC position, otherwise the maximum pressure pushing the piston will not be reached, which will lead to a decrease in the torque developed by the engine.

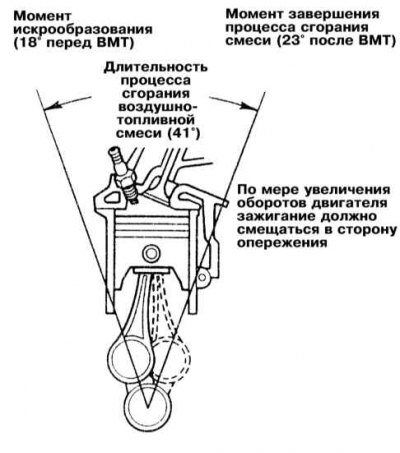

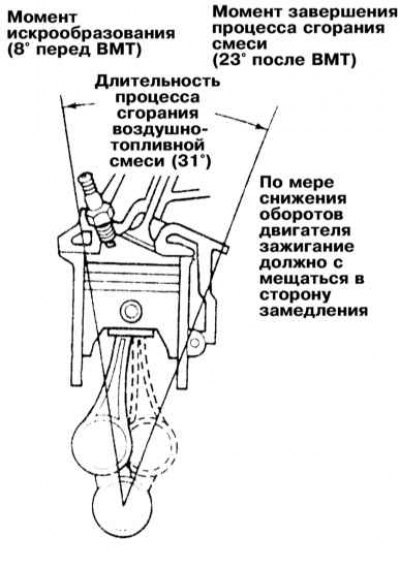

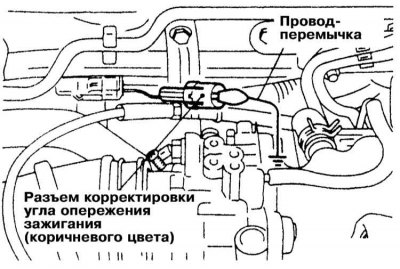

If you set the ignition timing to 10°before TDC, then the ignition of the air-fuel mixture in each of the cylinders will occur at the moment when the corresponding piston takes the corresponding position (10°before TDC of the end of its compression stroke). The foregoing remains true only while the engine is idling. To achieve maximum efficiency of engine output/fuel savings can be achieved if the process of combustion of the mixture in the cylinders is completed within 23°after the TDC of the corresponding piston.

|  |

As the engine speed increases, the pistons begin to move faster, while the spark plugs must ignite the air-fuel mixture so that its combustion occurs even a little earlier than the moment when the corresponding piston reaches the TDC position. If the ignition is set too early, the increasing pressure in the cylinder will prevent the piston from moving up, resulting in a characteristic knock, colloquially referred to as detonation. Too late ignition, as mentioned above, leads to a noticeable decrease in the efficiency of the engine's output.

Special alignment marks are provided on the rim of the crankshaft pulley and the timing cover. In this case, the mark on the pulley corresponds to the TDC position of the end of the compression stroke of the piston of the first cylinder, to the spark plug wire of which a stroboscope should be connected when checking / adjusting the ignition timing (make sure that the wiring for connecting the stroboscope does not touch the blades of the cooling fan!). In this case, the flashes of the lamp will occur synchronously with the moments of sparking between the electrodes of this candle. By pointing the stroboscope beam at the pulley rim, you can easily determine the position of the piston of the first cylinder at the moment the mixture starts to ignite - a mark on the pulley rim "freeze" opposite the corresponding division of the scale fixed on the timing cover. When adjusting the ignition timing, it is necessary to achieve compliance with the regulatory requirements for this car model (see below).

Check and adjustment

Models 1990-1996 issue

1. Set the parking brake, start the engine and warm it up to normal operating temperature. Turn off all onboard electrical consumers, bring the front wheels of the car to a straight position. Engage neutral (models with manual transmission) / move the selector lever to position "R" (models with AT).

2. Make sure that the idle speed is set correctly.

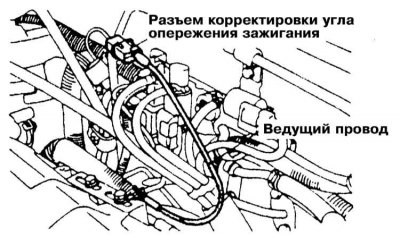

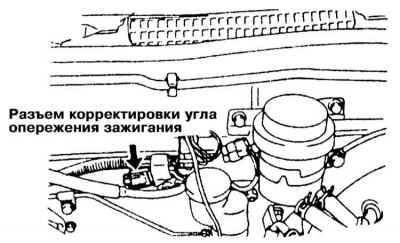

3. Stop the engine, remove the splash guard from the ignition timing adjustment connector. Use a jumper wire to ground the connector terminal to ground.

|  |

|  |

|  |

4. Connect the tachometer, connect the stroboscope to the BB wire of the spark plug of the first cylinder. Start the engine and leave it running at idle.

5. Aim the stroboscope beam at the installation scale fixed next to the crankshaft pulley.

6. Loosen the ignition distributor/crankshaft angle sensor retaining nut.

7. Rotate the distributor/sensor housing to achieve the desired ignition timing setting, then tighten the fasteners and stop the engine.

8. Remove the jumper wire and install the splash guard on the connector.

9. Start the engine and repeat the test, this time without grounding the connector - the reading should move up by approximately 5°from the base setting. The engine control unit can adjust the ignition timing for a specific combination of input parameters.

10. Stop the engine, disconnect the stroboscope and tachometer.

Models 1997-2000 issue

On these models, the installation and adjustment of the ignition timing is carried out automatically under the control of the electronic module (ECM). Checking can be done using a special diagnostic reader (scanner).