Tool

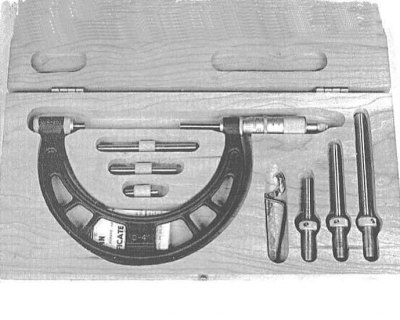

Micrometer with a set of nozzles

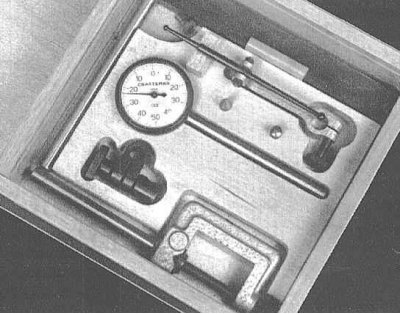

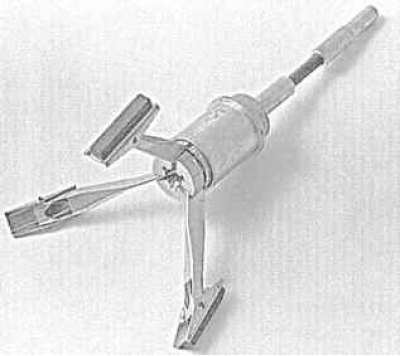

Dial meter with a set of clamps and nozzles

Dial/vernier caliper

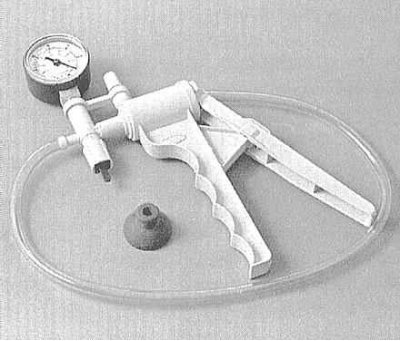

Vacuum pump with manual drive

stroboscope

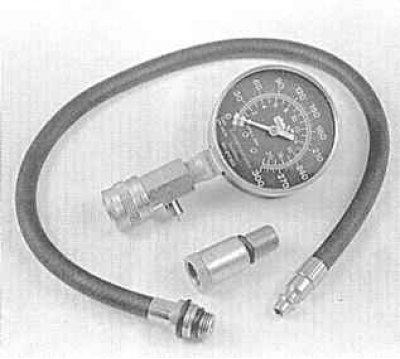

Compression tester with a nozzle for installation in spark plug holes

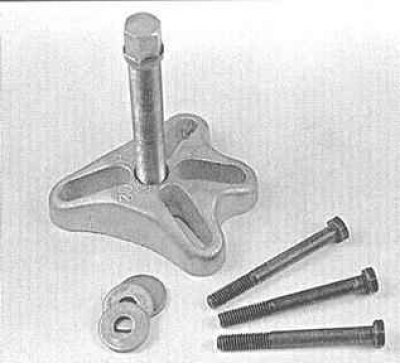

Damper/Steering wheel puller

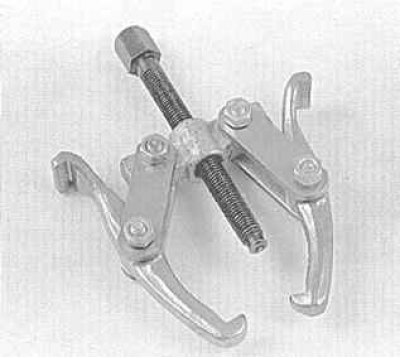

General purpose puller

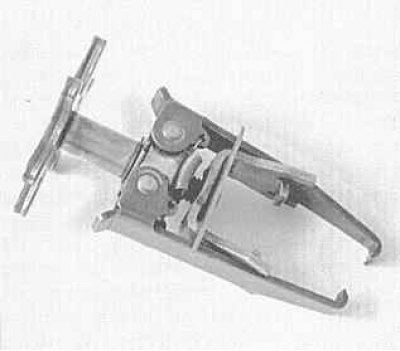

Hydraulic tappet removal tool

Valve spring compression tool

Valve spring compression tool

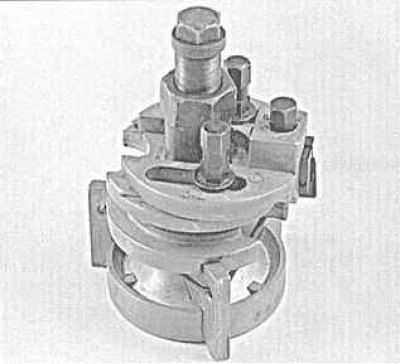

Countersink for removal of stepped wear in the cylinder

Piston ring cleaner

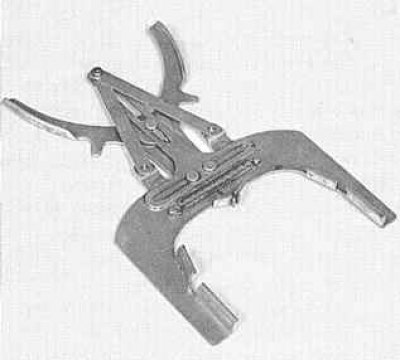

Piston ring removal/installation tool

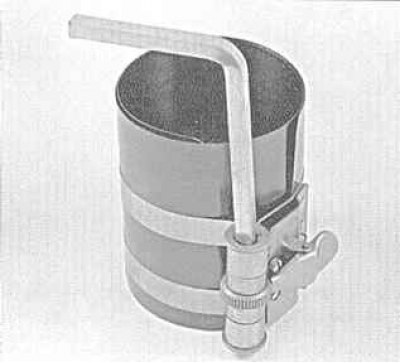

Piston ring crimping tool

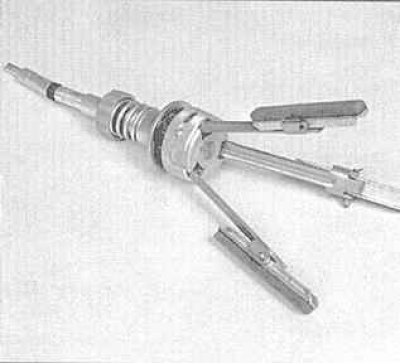

Hone for processing cylinder mirrors

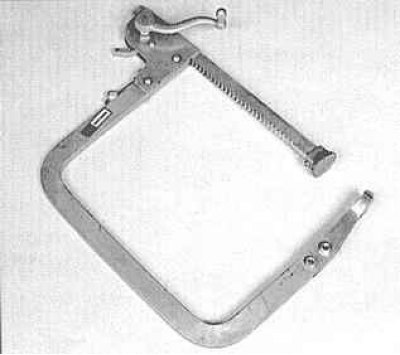

Brake shoe guide spring cup removal tool

Hone for processing brake cylinders

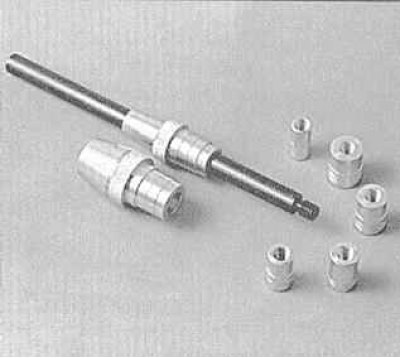

Clutch Alignment Tool

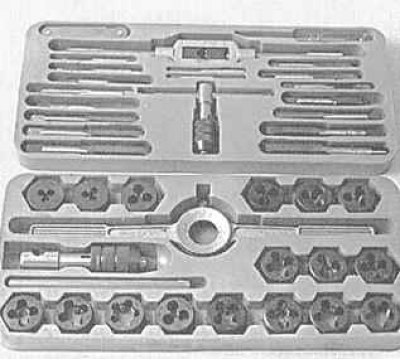

Set of taps and lerok

The choice of a good tool is one of the basic requirements for anyone who plans to perform car maintenance or repair procedures on their own. At first glance, the costs associated with acquiring the required set of tools may seem too high, but when compared with the costs associated with the performance of routine maintenance procedures and the simplest car repairs at a service station, they turn out to be quite reasonable.

To assist the average car enthusiast in choosing the right tool for the various car care procedures described in this manual, below are lists of three tool kits, tentatively titled: Routine Maintenance and Minor Repair Tool Kit; a set of tools for general and major repairs and a special tool. Vehicle owners with no practical experience in mechanical work should start by performing procedures limited to the use of tools from the first list, while improving their skills and gradually expanding the range of tools used. As you gain experience, you can move on to more complex tasks, complementing the set of tools at hand. After some time, the acquired skills will allow you to start performing more complex work that requires the use of a tool from the second list (for general and major car repairs). When your qualifications begin to allow you to save significant funds on the independent implementation of complex repair procedures, you can consider purchasing a special tool.

A set of tools for routine maintenance and minimal car repairs

The list below includes the minimum tools required to perform routine maintenance and minor vehicle repairs. It is recommended to purchase a set of combination wrenches (with a regular open end on one end and a flare on the other), despite the high cost of such a kit compared to the cost of a set of conventional wrenches, the costs will be justified, because. these keys have the benefits of both types.

- combination wrench set (1/4 - 1 inch; 6 - 19 mm)

- adjustable wrench

- Probe set

- Nipple wrench for bleeding brakes

- Screwdrivers:

- with a flat sting (150 mm long and 8 mm in diameter)

- With a cross sting (No. 2 x 6 inches (150mm long)

- Combination pliers

- Hacksaw with a set of blades

- Tire pressure gauge

- Grease gun (syringe)

- oil canister

- Fine sandpaper

- Wire brush

- Tool for stripping terminals and battery wire contacts

- Oil filter wrench

- Funnel (medium size)

- Supports for fixing the car in a raised position, 2 pcs

- Drainage tank

A set of tools for general and overhaul of a car

This tool is necessary when carrying out any car engine repair operations and is offered in addition to the first list. This listing includes a complete set of interchangeable sockets. At a significant cost, a set of interchangeable heads brings invaluable benefits due to its versatility and ease of use - especially in combination with the various types of actuators included in the kit. It is recommended to use 1/2" drives preferably (not 3/8 inch), because they, although more expensive, can be used with almost any type of torque wrench (Ideally, a good mechanic should have both types of drives at his disposal). A cheaper alternative to a set of interchangeable sockets is a set of tubular wrenches.

- Set of interchangeable sockets (including type heads "Torx") (or tubular wrenches), sizes corresponding to the sizes of wrenches from the previous list /

- Ratchet reversible drive (for use with interchangeable sockets)

- Gate length 250 mm

- Universal (gimbal type) hinge (for use with sockets)

- torque wrench (with drive of the same size as for interchangeable sockets)

- Round Face Hammer - 8 oz (about 230 g)

- Soft-faced hammer (plastic or rubber) (mallet)

- Screwdrivers:

- with a flat sting (150 mm long and about 6.5 mm in diameter)

- with a flat sting (strong No. 2, 8 mm)

- With a cross sting (No. 3 x 8 inches (203 mm))

- With a cross sting (strong No. 2)

- Clamping pliers

- Pliers:

- narrow-nosed (needle nose pliers)

- For retaining rings (internal and external)

- Chisel - 1/2 inch (13 mm)

- Scraper (made of flattened and pointed at one end of a copper tube)

- scriber (scriber)

- Kerner

- Beards with a thin sting (1.6, 3.2, 4.8mm)

- Steel Ruler / Flatness Gauge

- Allen key set (Allen) (for heads with internal hexagon)

- File set

- Wire brush (big)

- Second set of supports

- Jack (hydraulic or scissor type)

Note. Another tool in constant demand is a 3/8" chuck electric drill (up to 9.5 mm) with a set of good quality drill bits.

Special tool

This list includes tools that are quite expensive, are not required regularly, or require the manufacturer's instructions to be followed when using. If your area of activity does not include the frequent performance of complex mechanical operations, the acquisition of such a tool will be a bad investment. It is reasonable to buy it in clubbing with friends or rent it in car service workshops.

The list includes only those tools that can be found in retail trade or which are produced for distribution to the dealer offices of firms. Sometimes in the text of the Manual you will find references to such special tools. Usually, the authors try in parallel to propose an alternative method that avoids the obligatory use of a hard-to-reach tool. If it is impossible to avoid the use of a special tool, and acquiring it for use is problematic, it is better to entrust the performance of the relevant work to car service specialists.

- Valve spring compression tool

- Piston ring cleaner

- Piston ring crimping tool

- Piston ring installer

- Cylinder Compression Gauge (compressometer)

- Countersink for processing the edges of cylinders

- Hone for processing cylinder mirrors

- Cylinder diameter gauge

- Micrometer (micrometers) and/or dial caliper

- Hydraulic tappet removal tool

- ball joint separator

- Universal type puller

- impact screwdriver

- Dial meter set

- Manual combination pump (vacuum/pressure)

- Tachometer

- Universal tester for electrical measurements

- lifting rigging

- Brake spring removal/installation tool

- floor jack

Purchasing a tool

A novice mechanic in terms of acquiring the necessary tools for performing routine maintenance and repair of a car can be offered several practical tips. When preparing for routine maintenance or minor vehicle repairs, it is wise to purchase the tool separately. On the other hand, in the case of planning extensive work, it is easier and more reliable to buy a set of modern tools in a retail store. Purchasing a kit usually costs somewhat less than individual purchases and is often supplemented with an attached tool box. In the future, to expand the choice, individual tools, additional kits and a larger tool box can be purchased. The gradual expansion of the set of tools will allow you to stretch the costs and decide on the choice of really necessary tools.

Specialized tool magazines are the only source for some specialty tools, but whatever the source, avoid cheap purchases, especially for screwdrivers and replacement sockets, as they will likely not last long. As a result, the costs associated with the replacement and restoration of a cheap tool will be incomparably more significant than the costs of a one-time purchase of a quality product.

Tool care and storage

A good tool is a valuable investment, so it is wise to take care to keep it clean and ready for use at all times. After using the tool, always thoroughly wipe the surface with a clean, dry cloth before storing it to remove any dirt, grease, and metal particles. Never leave tools scattered around the work area. After completing the work, carefully check the area under the hood and under the car for the presence of a forgotten tool.

For storing tools such as screwdrivers, pliers, hammers, etc. a tool comb mounted in a convenient location on the garage wall is ideal. Sets of wrenches and interchangeable sockets should be stored in metal boxes. The measuring tool must be stored in a dry and clean place inaccessible to corrosion.

You should always pay attention to the condition of the working surfaces of the tool. The impact part of the hammer head is subject to riveting during operation, screwdrivers lose sharpening of their stings over time. Don't be stingy with taking a little time and attention to use sandpaper or a file to remove rivets and tidy up the cutting edges. Replace irreparably worn or damaged tools.

With careful care, the tool will serve you faithfully for a very long time.

Workplace equipment

Speaking about the tool, it is impossible not to mention the equipment of the workplace. If more serious work is to be done than simple maintenance, care should be taken to prepare a suitable work site.

We have to admit that many motorists are forced to remove the engine and other similar work far from being in a garage or workshop. However, in any case, an important requirement is the presence of a roof or awning.

Whenever possible, any procedures for disassembling parts of vehicle systems should be carried out on a clean, flat workbench, or a sturdy table at a convenient height. The workbench must be equipped with a vise. Sufficient is the presence of a vise with a jaw opening of up to 100 mm and with soft pads on the jaws.

As mentioned above, the work site must be equipped with a clean, dry place for storing tools, lubricants and cleaning fluids, fillers, paints and varnishes, etc.

It should be noted that an absolutely necessary tool is an electric drill, therefore, the work site must be equipped with a power source to connect it. The presence of a drill with a chuck up to 9.5 mm and a set of high-quality drills will greatly facilitate many procedures.

Finally, the workplace should always have an adequate supply of old newspapers and clean, lint-free rags for cleaning the work area, tools, and vehicle parts.

Waste should be handed over to recycling centers in sealed containers.

Never do any work on the bare painted surface of the car, use protective fender pads, or, at worst, cover the polished surfaces with old blankets.