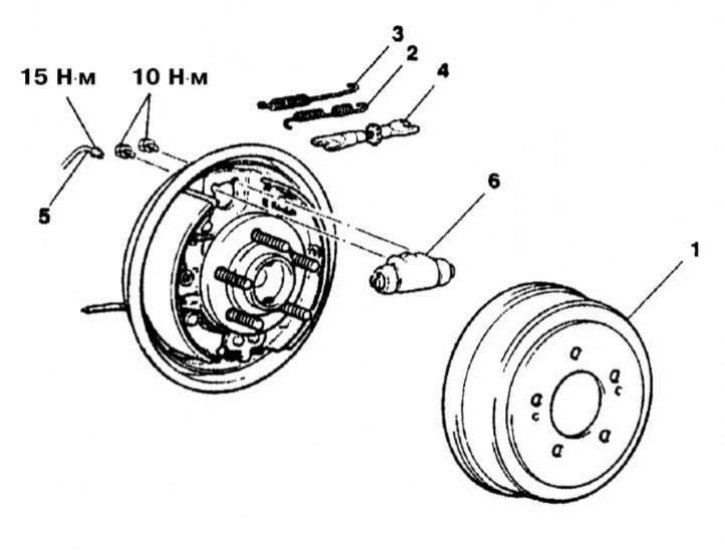

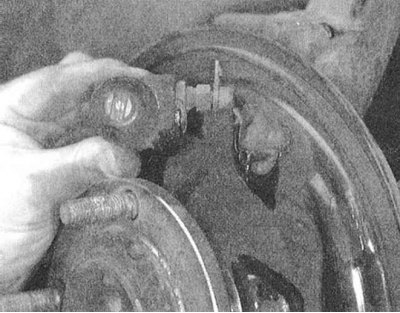

Details of installation of the wheel cylinder of the drum brake mechanism (Galant models)

1 - Brake drum; 2 - Spring fastening the shoe to the adjusting lever; 3 - Upper coupling spring; 4 - Assembly of the automatic regulator; 5 - Brake tube; 6 - Wheel cylinder

Removing

1. The installation details of the drum brake wheel cylinder are shown in the illustration.

2. Jack up the car and put it on stands.

3. Remove the shoe-to-adjustment lever spring.

4. Remove the top return spring.

5. Remove the automatic regulator assembly.

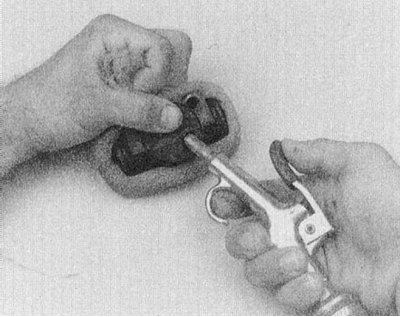

6. Prepare a drain container and disconnect the brake pipe from the wheel cylinder.

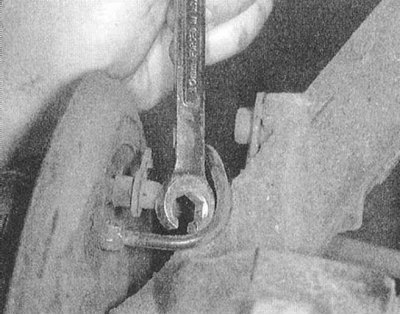

Attention! To loosen the union nut, in order to avoid rounding the corners of its slots, you should use a special ring wrench with a split head - get ready to collect the spilled liquid!

|  |

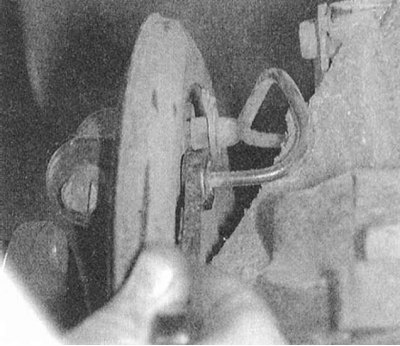

7. Turn out fixing bolts and remove assembly of the wheel cylinder from a brake board.

|  |

Refurbishment

1. The compilers of this Guide recommend that car owners avoid rebuilding brake components whenever possible, preferring to replace worn components.

2. If replacement parts are not readily available, wheel cylinder refurbishment can be done as described below.

3. First of all, care should be taken to minimize the risk of dirt getting into the hydraulic path of the brake system. Use only clean brake fluid to add to the system - if necessary, flush the entire brake path, fill it with fresh fluid and pump it.

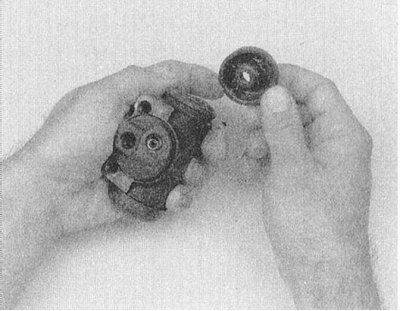

4. Remove the wheel cylinder from the brake shield and transfer it to a clean workbench.

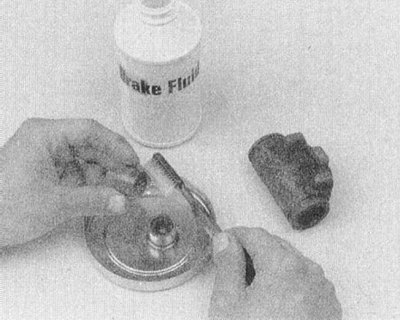

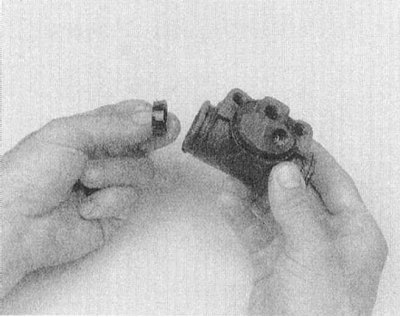

5. Remove anthers and release pistons from the cylinder.

Note. When assembling the cylinder, the anthers must be replaced without fail. Prepare a repair kit.

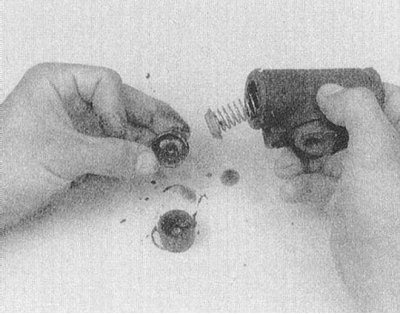

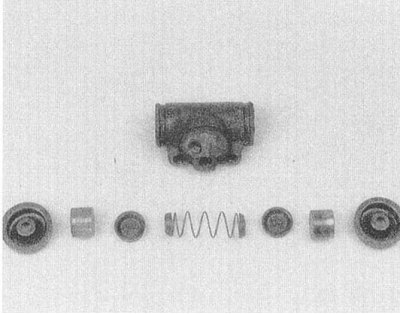

6. The pistons of the wheel cylinder are equipped with sealing collars and are spread out by a spring located between them. Remove all components from the cylinder assembly - use compressed air if necessary. In the absence of access to a source of compressed air, special care should be taken not to damage the cylinder mirrors when removing components. All components included in the repair kit must be replaced.

|  |

7. Thoroughly flush all metal components, including the cylinder body, with denatured alcohol or clean brake fluid.

Attention! Never use gasoline, kerosene, thinners or other petroleum products to flush the brake components, which can lead to the destruction of rubber sealing components.

8. Dry all parts thoroughly (using compressed air if possible), - do not use rags to dry the components to avoid getting fluff inside the cylinder.

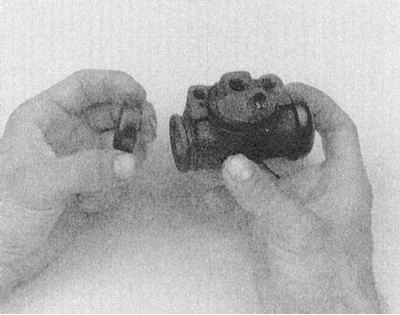

9. Carefully inspect the working surfaces of the cylinders. In case of detection of scratches, scoring and other mechanical defects, replace.

10. Arrange the prepared components in the order in which they are installed in the cylinder assembly.

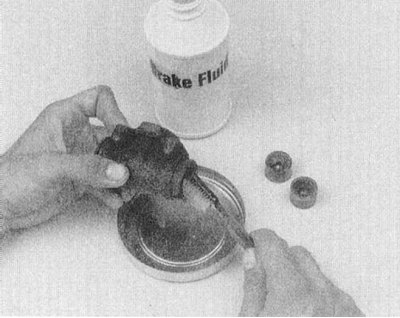

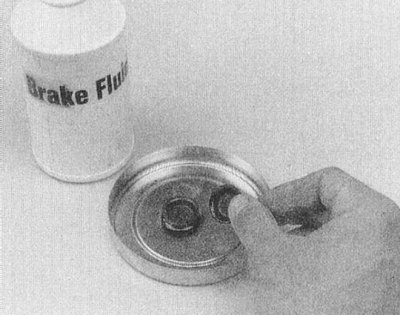

11. Lubricate the cylinder mirrors and piston seals with clean brake fluid.

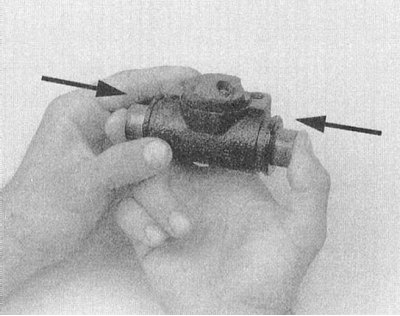

12. Install the inner cups, then fill the pistons into the cylinder.

|  |

|

13. Manually, without the use of any tools, seat the anthers in the receiving grooves.

Installation

1. Install the cylinder in its regular place on the shield of the brake mechanism. Screw in the mounting bolts and tighten them with the required force (10 Nm).

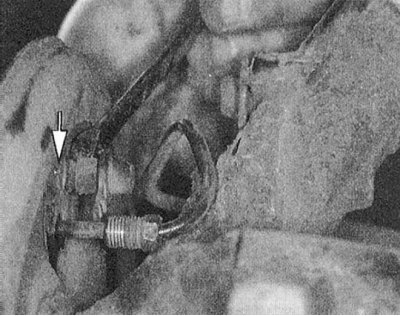

2. Connect the brake line to the cylinder by tightening the union nut of its union connection with a force of 15 Nm.

3. Add fresh brake fluid to the GTZ reservoir and loosen the bleed valve of the wheel cylinder being installed - the fluid will begin to fill the cylinder, which will reduce the time spent later on bleeding the circuit.

4. Install the automatic regulator assembly.

5. Install the top return spring.

6. Install the shoe-to-adjuster arm spring.

7. Install the brake drum.

8. Install the wheel, lower the vehicle to the ground and bleed the brake circuit (see Section Bleeding the brake system).