Warning! Remember that the dust produced during the operation of the brake mechanisms may contain asbestos, which is extremely harmful to human health. Never blow off dust with compressed air or inhale it - wear a protective mask or respirator when servicing mechanisms. Never use gasoline or petroleum-based solvents to clean brake system components - use only branded cleaners or methyl alcohol!

Mirage models since 1993, Diamante and Galant

Brakes front and rear wheels

Note. The procedure described below is the same for both front and rear disc brakes.

Removing

1. Jack up the car and put it on stands.

2. Remove the corresponding wheel.

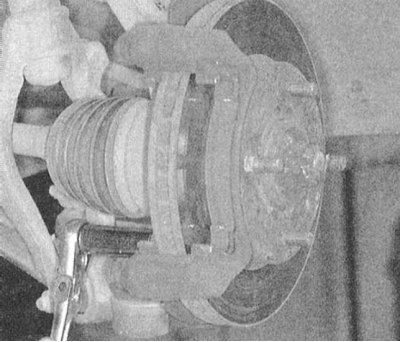

3. Remove the caliper, brake pads (see Section Replacing disc brake pads) and anchor bracket.

|  |

4. Without disconnecting the hydraulic hose, tie the caliper with wire to the suspension elements - make sure that the flexible brake hose is not stretched.

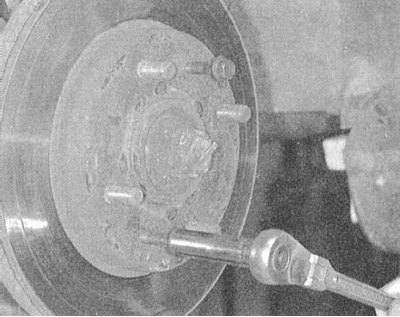

5. On some models, the brake disc is attached to the wheel hub with two small screws - unscrew the screws and remove the disc. If the disk "stuck" and cannot be removed, screw a pair of suitable bolts into the threaded holes provided in the disc body and, gradually tightening them, release the disc.

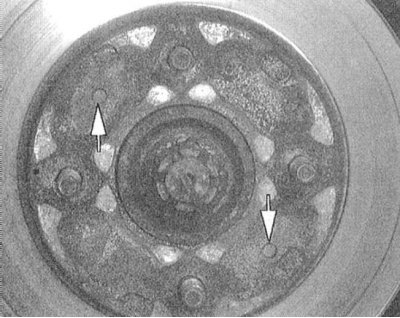

|  |

|  |

Examination

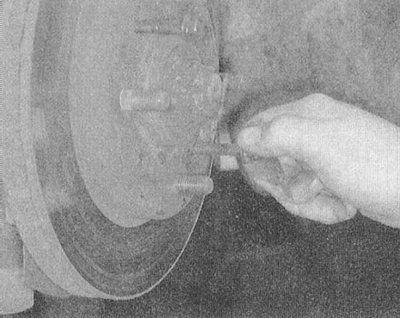

1. Using a micrometer, measure the thickness of the disc at eight different points on its surface, spaced approximately 45°apart and about 10 mm from the outer assembly. The minimum allowable disc thickness is 22.4mm (for front brakes) /8.4mm (for rear mechanisms), the deviation should not exceed 0.015 mm.

2. A disk worn below the permissible limit must be replaced.

3. In case of detection of variations exceeding the norm, give the disk a groove.

Note. As a result of turning, the thickness of the restored disk should not fall below the minimum allowable limit (see above).

Installation

1. Install the disc on the hub, screw in and tighten the fixing screws.

2. Install anchor shackle and brake pads.

3. Replace the caliper, screw in and tighten the guide pins.

4. Install the wheel, lower the vehicle to the ground and tighten the wheel nuts.

5. Before starting the operation of the car, depress the brake pedal several times to shrink the components of the brake mechanism.

Mirage models through 1992 no.

Front wheel brakes

Removing

1. Without lifting the wheels off the ground, with the brakes applied, loosen the hub nut.

2. Jack up the car and put it on stands.

3. Remove the relevant wheel.

4. Remove the hub nut and lock washer.

5. Remove the brake caliper and, without disconnecting the brake hose, tie the assembly with wire to the suspension element - make sure that the flexible brake hose is not stretched.

6. Remove the brake pads.

7. Release the lower control arm ball joint and tie rod end from the steering knuckle assembly.

8. Using a puller, release the drive shaft from the hub assembly.

9. Turn out the lower fixing bolts and remove a rack of a suspension bracket.

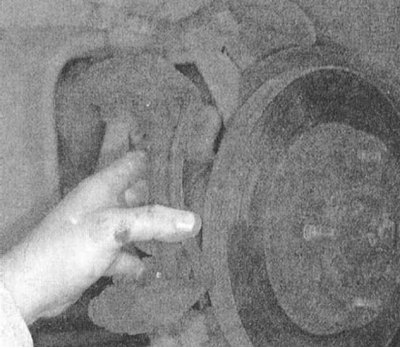

10. Turn out fixing bolts and remove anchor bracket of the brake mechanism.

11. To separate the brake disc from the hub, unscrew the fixing bolts and use the MB991001 tool.

Examination

1. Using a micrometer, measure the thickness of the disc at eight different points on its surface, spaced approximately 45°apart and about 10 mm from the outer assembly. The minimum allowable disc thickness is 22.4mm (for front brakes) /8.4mm (for rear mechanisms), the deviation should not exceed 0.015 mm.

2. A disk worn below the permissible limit must be replaced.

3. In case of detection of variations exceeding the norm, give the disk a groove.

Note. As a result of turning, the thickness of the restored disk should not fall below the minimum allowable limit (see above).

Installation

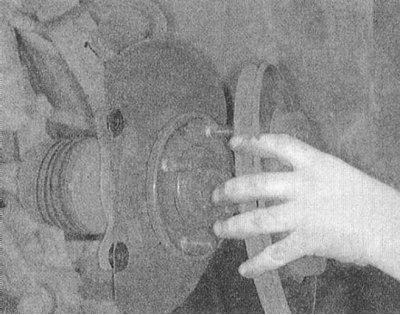

1. Install the brake disc on the hub. Tighten the fixing nuts to the required torque (54 Nm) and install the assembly on the car.

2. Install washer (chamfer out), screw in and temporarily tighten the hub nut.

3. Fix on the regular places a spherical support of the lower suspension arm and a tip of steering draft.

4. Install the brake components.

5. Install the wheel and lower the vehicle to the ground.

6. Squeeze out the foot brake and tighten the hub nut to the required torque (260 Nm). Insert a new cotter pin and straighten it securely "antennae".

Front wheel brakes

Removing

1. Jack up the car and put it on stands.

2. Remove the relevant wheel.

3. Disconnect the parking brake actuator from the caliper.

4. Remove the caliper, brake pads and anchor bracket.

5. Without disconnecting the brake hose, tie the assembly with wire to the suspension element - make sure that the flexible brake hose is not stretched.

6. Remove the brake disc from the hub assembly.

Examination

1. Using a micrometer, measure the thickness of the disc at eight different points on its surface, spaced approximately 45°apart and about 10 mm from the outer assembly. The minimum allowable disc thickness is 22.4mm (for front brakes) /8.4mm (for rear mechanisms), the deviation should not exceed 0.015 mm.

2. A disk worn below the permissible limit must be replaced.

3. In case of detection of variations exceeding the norm, give the disk a groove.

Note. As a result of turning, the thickness of the restored disk should not fall below the minimum allowable limit (see above).

Installation

1. Install the disc on the hub and temporarily secure it with a pair of wheel nuts.

2. Install the anchor bracket and insert the brake pads into it.

3. Install the caliper on the bracket. After fixing the caliper, the two temporary wheel nuts can be removed.

4. Connect the parking brake actuator to the caliper.