Warning! Remember that the dust produced during the operation of the brake mechanisms may contain asbestos, which is extremely harmful to human health. Never blow off dust with compressed air or inhale it - wear a protective mask or respirator when servicing mechanisms. Never use gasoline or petroleum-based solvents to clean brake system components - use only branded cleaners or methyl alcohol!

Note. Service the brake assemblies one by one - if necessary, the second one can be used as a sample.

1. Remove the brake drum (see Section Removal, installation and check of a condition of a brake drum).

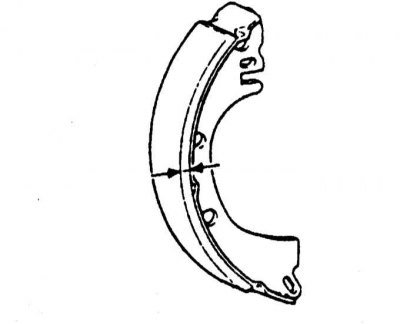

2. Measure the residual thickness of the friction linings of the brake shoes.

3. When the wear of the linings is below the maximum allowable value (1.0 mm) replace shoes with drums.

Note. To prevent the vehicle from losing directional stability during braking, the replacement of brake components must be carried out for both assemblies of the same axle as a set.

4. If there is a noticeable difference in the residual thickness of the pads on the left and right sides of the car, check the proper functioning of the wheel cylinders and evaluate the condition of the working surfaces of their pistons.