Disassembly

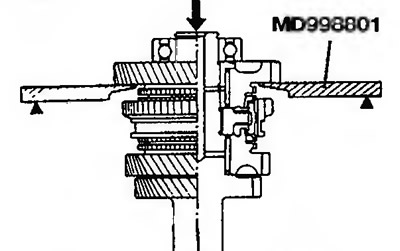

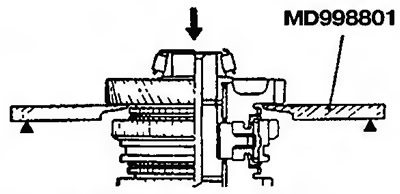

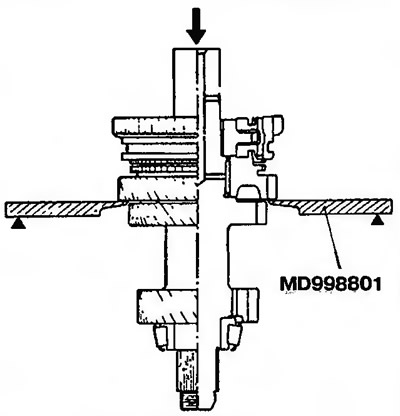

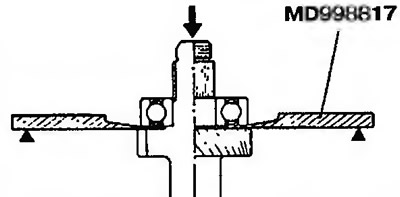

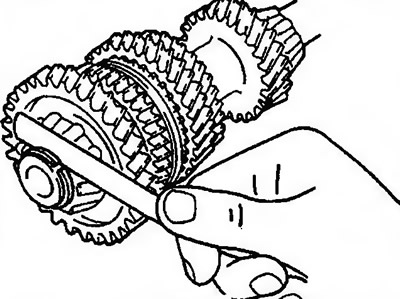

Removal of the ball bearing, tapered roller bearing and 1st gear is shown in fig. 11.33a, b, removing the synchronizer hub for 1st and 2nd gear and the 2nd gear gear - in fig. 11.34, removal of the ball bearing - in fig. 11.35, removal of the tapered roller bearing - in fig. 11.36.

Pic. 11.33a. Removing the ball bearing |

Pic. 11.33 b. Removing the tapered roller bearing and 1st gear |

Pic. 11.34. Removing the synchronizer hub for 1st and 2nd gear and 2nd gear |

Pic. 11.35. Removing the ball bearing |

Pic. 11.36. Removing the tapered roller bearing

Examination

Intermediate shaft

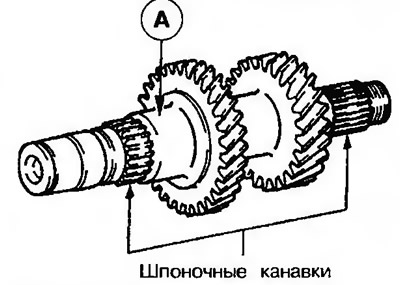

1. Check the outer surface of the layshaft for damage, excessive wear and pitting in location A of the needle bearing (pic. 11.37).

Pic. 11.37. Check the outer surface of the layshaft for damage, excessive wear and pitting in location A of the needle bearing

2. Check the keyways for damage and wear.

Assembly

Snap ring

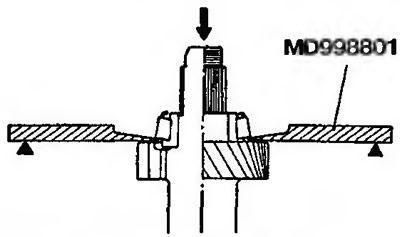

3. Select and install a circlip such that the countershaft bearing end clearance is correct (pic. 11.38).

Pic. 11.38. Installing the snap ring and checking the axial clearance of the intermediate shaft bearing

Axial clearance of intermediate shaft bearing, automatic transmission F4M21, F5M21, F5M22, W5M33: 0.01 - 0.14 mm.