General information

Exhaust gas recirculation system reduces nitrogen oxide emissions (NOx). If the combustion temperature of the air-fuel mixture is high, then a large amount of nitrogen oxides is formed in the combustion chamber. Therefore, the exhaust gas recirculation system feeds part of the generated gases into the combustion chamber in order to lower the temperature of the air-fuel mixture, which, in turn, leads to a decrease in the content of nitrogen oxides. The performance of the EGR system is controlled by the EGR valve so as not to reduce engine power.

Working mode

Under one of the following conditions, the exhaust gas remains closed, which prevents exhaust gas recirculation. Under normal driving conditions with a warm engine, the EGR valve opens and EGR starts.

- Low engine coolant temperature.

- The engine is running at idle.

- The engine runs at full throttle.

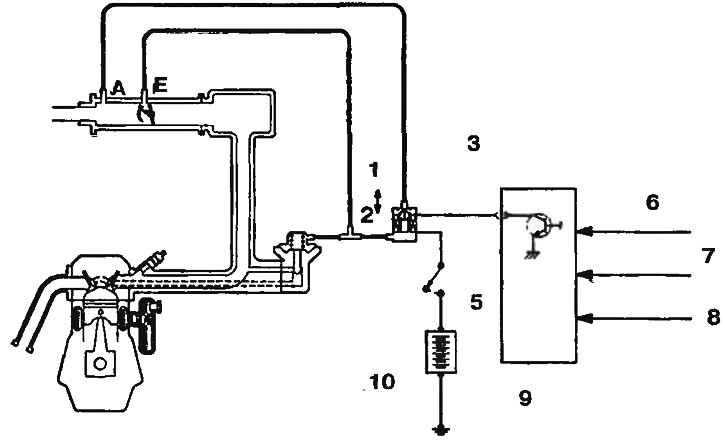

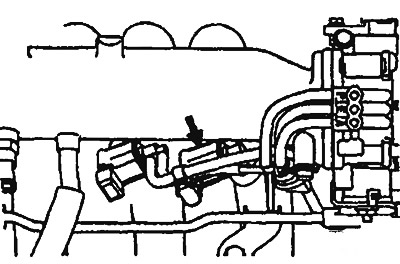

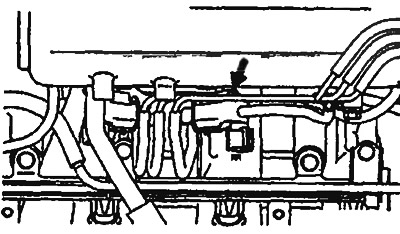

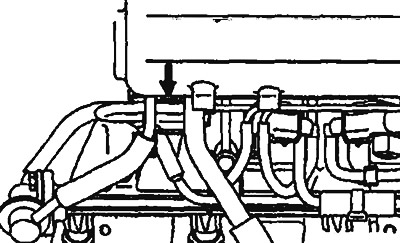

The diagram of the exhaust gas recirculation system is shown in fig. 6.10. The arrangement of the electromagnetic valve of system recirculation of the fulfilled gases is shown on fig. 6.11a-e.

Pic. 6.10. Scheme of the exhaust gas recirculation system: 1 - ON; 2 - OFF; 3 - Solenoid valve for controlling the exhaust gas recirculation system; 4 - Valve of the exhaust gas recirculation system; 5 - Control relay 6 - Air flow meter 4G9; 7 - Coolant temperature sensor; 8 - Crank angle sensor; 9 - Engine control unit; 10 - Battery

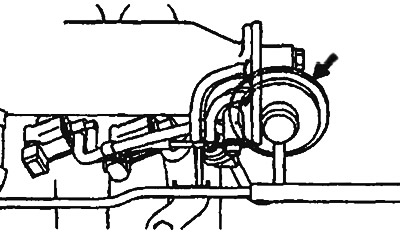

Pic. 6.11a. Location of the solenoid valve of the exhaust gas recirculation system of the 4G1 engine |

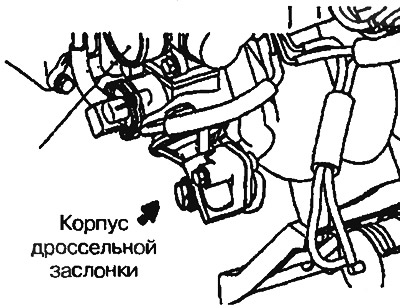

Pic. 6.11b. Location of the solenoid valve of the exhaust gas recirculation system of the 4G9 engine (except MW) |

Pic. 6.11c. Location of the solenoid valve of the exhaust gas recirculation system of the engine 4G9 - MW |

Pic. 6.11 EGR valve for 4G1 engine |

Pic. 6.11d. EGR valve for 4G9 engine