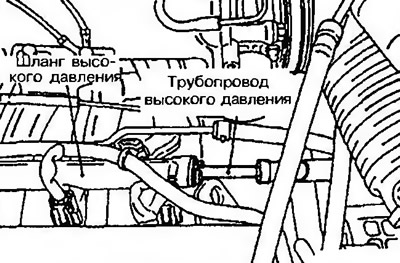

2. Disconnect the pipeline from the high pressure fuel hose (pic. 8.8).

Pic. 8.8. Disconnect the high pressure fuel line from the high pressure line

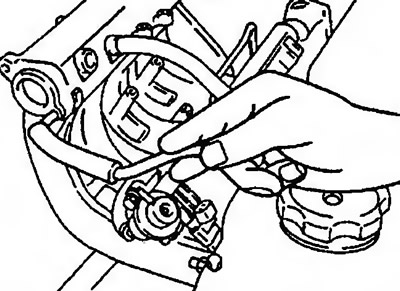

3. Connect adapter MD99-8742 with adapter MD998709 (pic. 8.9). Install the pressure gauge on adapter MD998709. When attaching the pressure gauge, use an o-ring or gasket to ensure a tight connection.

Pic. 8.9. Connect adapter MD998742 with adapter MD998709. Install pressure gauge on adapter MD998709

4. Install a pressure gauge with adapters between the high pressure line and the hose (pic. 8.10).

Pic. 8.10. Install a pressure gauge with adapters between the high pressure line and the hose

5. Connect the fuel pump connector with the shunt cable to the positive battery terminal and operate the fuel pump (pic. 8.11). Check the tightness of the pressure gauge connections and adapters, as the fuel is under pressure.

Pic. 8.11. Connect the fuel pump drive connector with the shunt cable to the positive battery terminal and drive the fuel pump

6. Disconnect the shunt wire from the pump drive terminal to stop the pump.

7. Start the engine and let it idle.

8. Measure the fuel pressure at idle. Normal value: 265 kPa at idle.

9. Disconnect the vacuum hose from the fuel pressure regulator and close its end with your finger (pic. 8.13). Measure fuel pressure. Normal value: 324-343 kPa at idle.

Pic. 8.13. Disconnect the vacuum hose from the fuel pressure regulator and close its end with your finger. Measure fuel pressure

10. Please note that the fuel pressure after repeated increase in engine speed at idle does not decrease.

11. While holding the fuel drain hose, increase the engine idling speed, then measure the pressure in the drain hose.

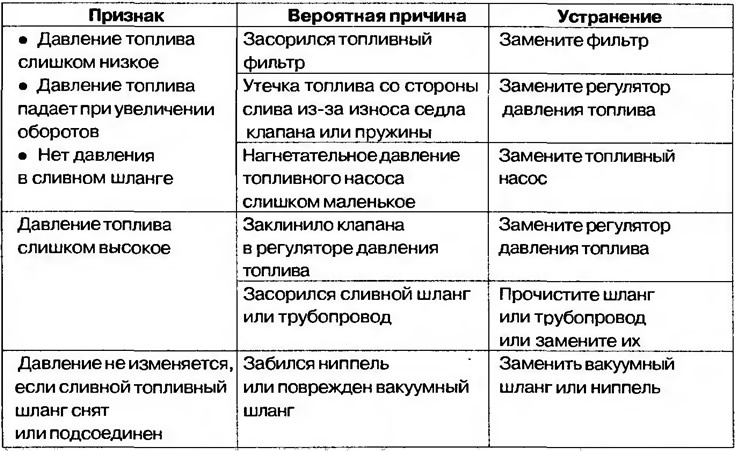

12. If the measured values of pressures of fuel deviate from norm, eliminate malfunctions according to the following table 8.7.

Table 8.7. Fuel pressure check

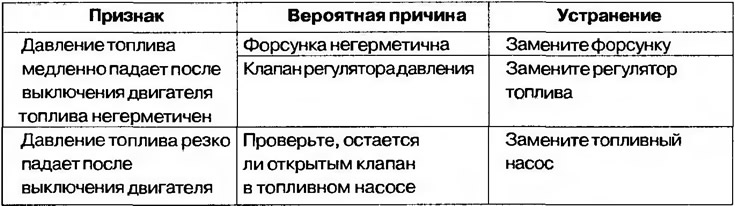

13. Turn off the engine and check the pressure gauge for changes. The condition is satisfactory, if the value for 2 minutes. does not decrease. If the value decreases, set the falling rate and troubleshoot according to table 8.8.

Table 8.8. Fuel pressure check (prod.)

14. Decompress the system.

15. Disconnect the pressure gauge and adapters from the system.

16. Replace the O-ring with the high pressure fuel hose connection. Apply engine oil to the gasket.

17. Push the high pressure hose onto the pipeline and tighten to a torque of 5 Nm.

18. Check for fuel leakage. Apply battery voltage to the fuel pump connector and operate the pump. Under fuel pressure, check the tightness of the system connections.