Rotor

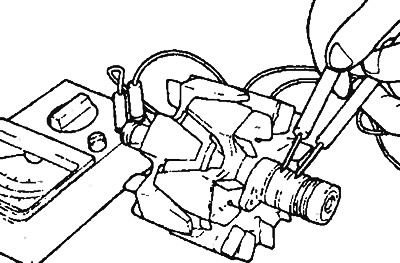

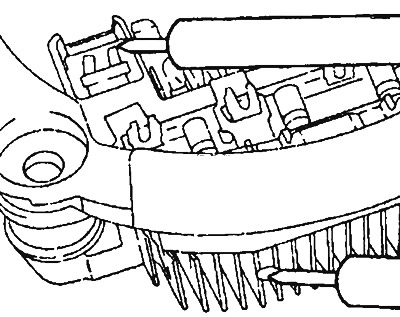

1. Check the field winding for electrical conductivity. Make sure there is continuity between the slip rings. If the resistance is very low, this indicates a short circuit (pic. 7.3). If there is no electrical conductivity or a short circuit, the rotor must be replaced. Resistance: approximately 2-5 ohms.

Pic. 7.3. Checking the field winding for electrical conductivity

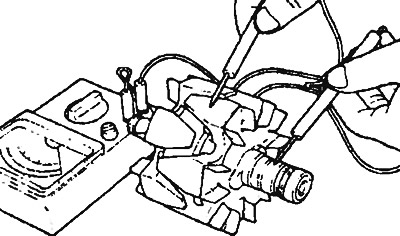

2. Check the field winding for a short to ground (pic. 7.4). Make sure there is no electrical conductivity between the slip rings and the core. Otherwise, the rotor must be replaced.

Pic. 7.4. Checking the field winding for a short to ground

Stator

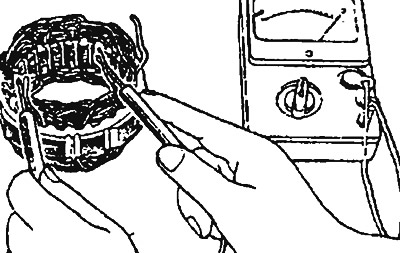

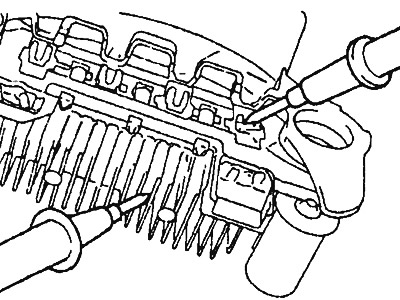

3. Check the electrical conductivity of the winding wires (pic. 7.5). If there is no electrical conductivity, the stator should be replaced.

Pic. 7.5. Checking the electrical conductivity of the stator winding

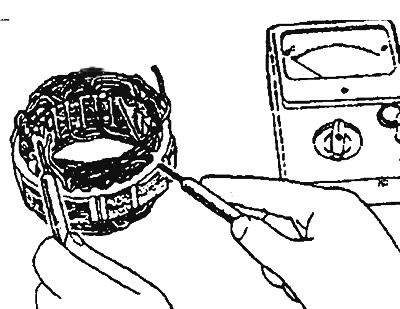

4. Check the contact of the stator winding with the housing (pic. 7.6). Make sure there is no electrical conductivity between the winding wire and the core. If present, the stator and rectifier should be replaced.

Pic. 7.6. Checking the contact of the stator winding with the housing

Rectifier

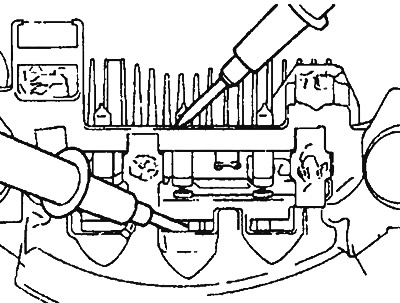

1. Using an ohmmeter, check the continuity between the positive rectifier and the stator winding wire connection terminal. If there is continuity in both directions, the diode has shorted. In this case, the rectifier must be replaced (pic. 7.7).

Pic. 7.7. Checking the positive rectifier

2. Using an ohmmeter, check the continuity between the negative rectifier and the stator winding wire connection terminal. If there is continuity in both directions, the diode has shorted. In this case, the rectifier must be replaced (pic. 7.8).

Pic. 7.8. Checking the negative rectifier

3. Use an ammeter to check the continuity of each of the three diodes at both ends. If there is no electrical conductivity in both directions, the diode under test has short circuited. In this case, the heat sink changes (pic. 7.9).

Pic. 7.9. Triple Diode Test

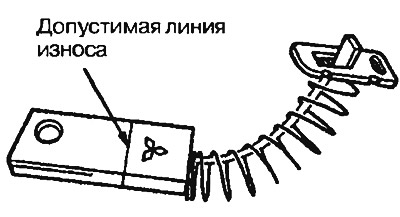

4. Brushes that are worn out more than allowed must be replaced (pic. 7.10).

Pic. 7.10. Generator brush

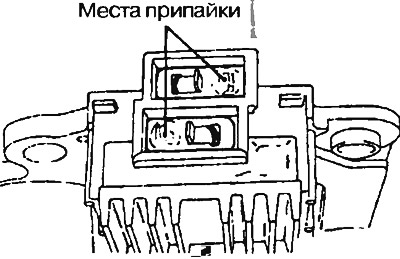

5. Connecting harnesses are soldered, the old brush with a spring is removed (pic. 7.11).

Pic. 7.11. Connecting harnesses are soldered, the old brush with a spring is removed

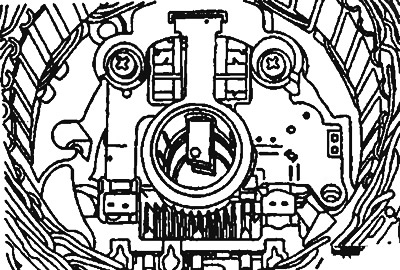

6. A new brush is installed in the brush holder and then the wire is soldered (pic. 7.12).

Pic. 7.12. A new brush is installed in the brush holder and then the wire is soldered