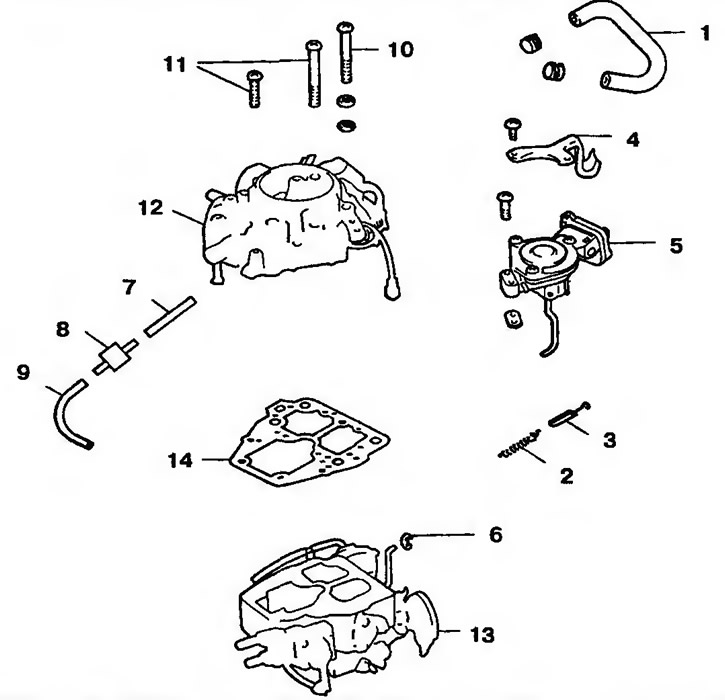

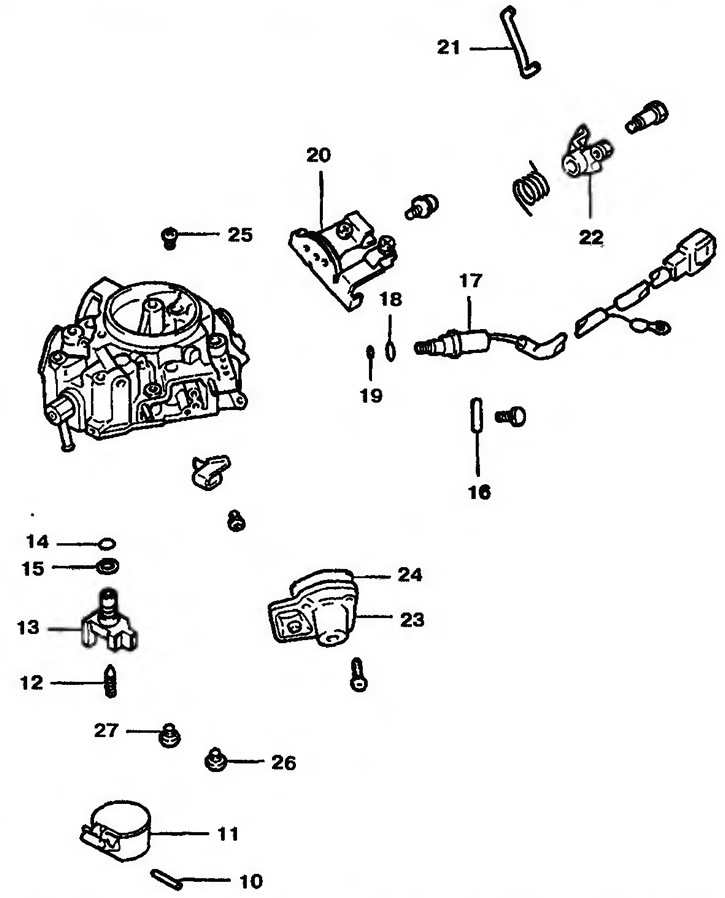

Pic. 10.25a. Carburetor type «WITH»: 1 - Branch pipe of the cooling system; 2 - Throttle valve return spring; 3 - Rubber shock absorber; 4 - Bracket for fastening the throttle return spring; 5 - Damper closing the throttle; 6 - Retainer; 7, 9 - Tubes; 8 - Retarding valve; 10 - Bolt for fastening the carburetor cover; 11 - Bolt with washer; 12 - Carburetor cover; 13 - Float chamber and throttle body; 14- Gasket

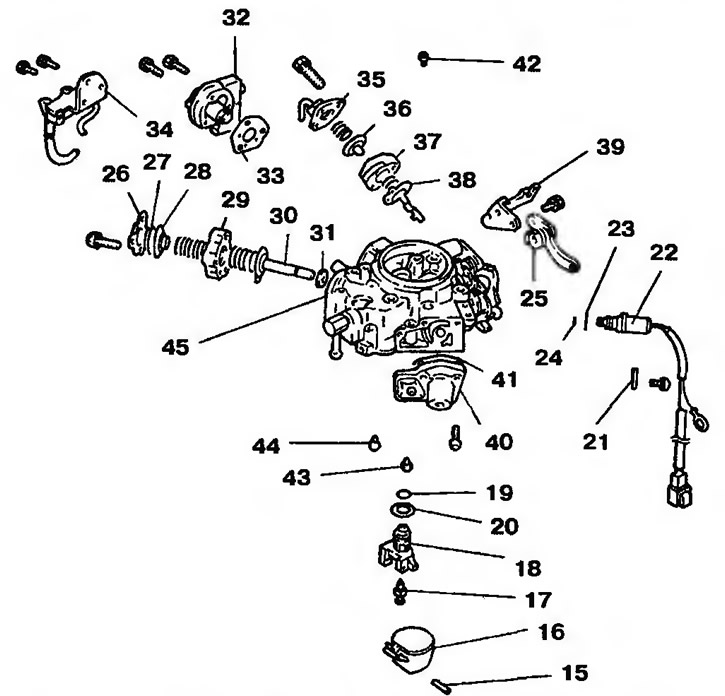

Pic. 10.256. Carb cover: 15 - Pin; 16 - float; 17 - Needle valve; 18 - Needle valve seat; 19, 33, 41 - Gaskets; 20, 23, 24 - O-rings; 21 - Retainer; 22 - Electromagnetic shut-off valve; 25 - Lever; 26, 35 - Covers; 27, 30, 36, 38 - Membranes; 28 - Valve; 29 - Spring seat; 31 - Valve; 32 - Valve for adjusting the amount of combustible mixture; 34 - Idling compensator; 37 - Housing; 39 - Bracket; 40 - Servo valve; 42 - Main air jet; 43 - Idle jet (primary); 44 - Idle jet (secondary); 45 - Carburetor cover

Pic. 10.25 a.m. Float chamber and throttle body: 46 - Weight; 47, 54 - Balls; 48 - Bolt; 49 - Gasket; 50, 51 - Main jets; 52 - Cork; 53 - O-ring; 55 - Float chamber; 56 - Tube; 57 - Decompression chamber; 58 - Gas lever; 59 - Cam follower; 60, 63, 64 - Adjusting idle speed bolts; 61 - Lever; 62 - Bracket; 65 - Adjusting bolt damper closing throttle; 66 - Adjusting bolt for the amount of combustible mixture; 67 - Secondary lever; 68 - Throttle body

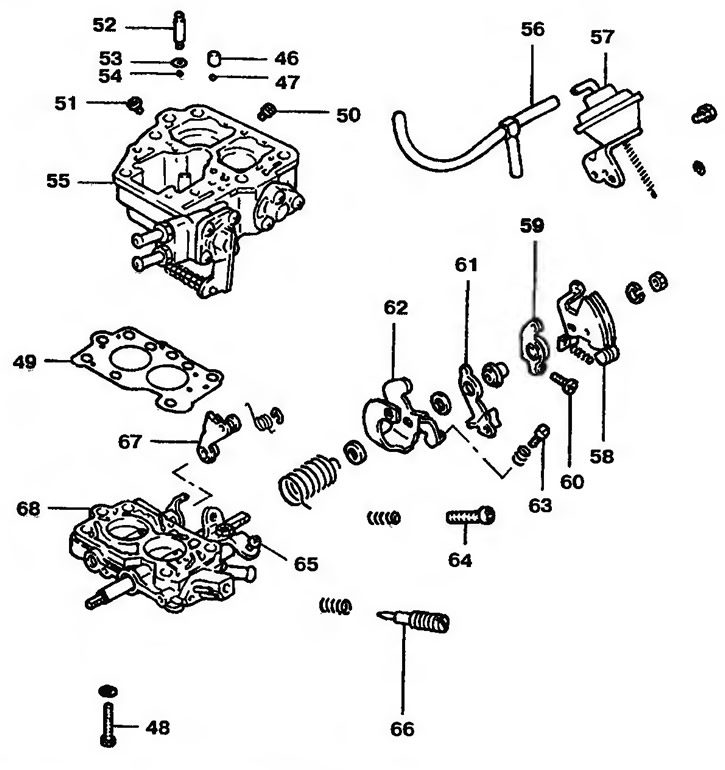

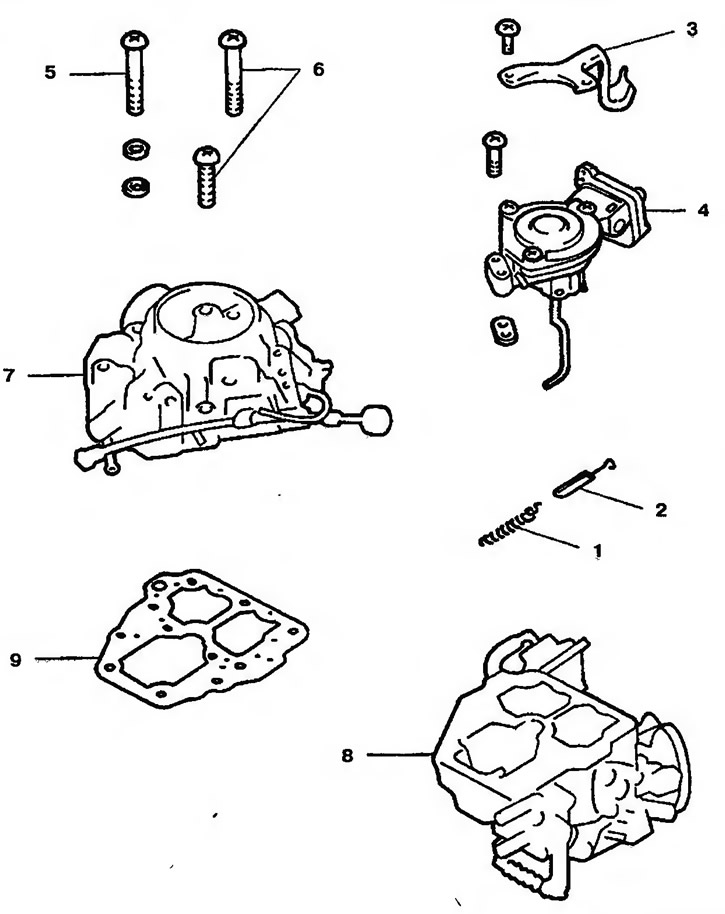

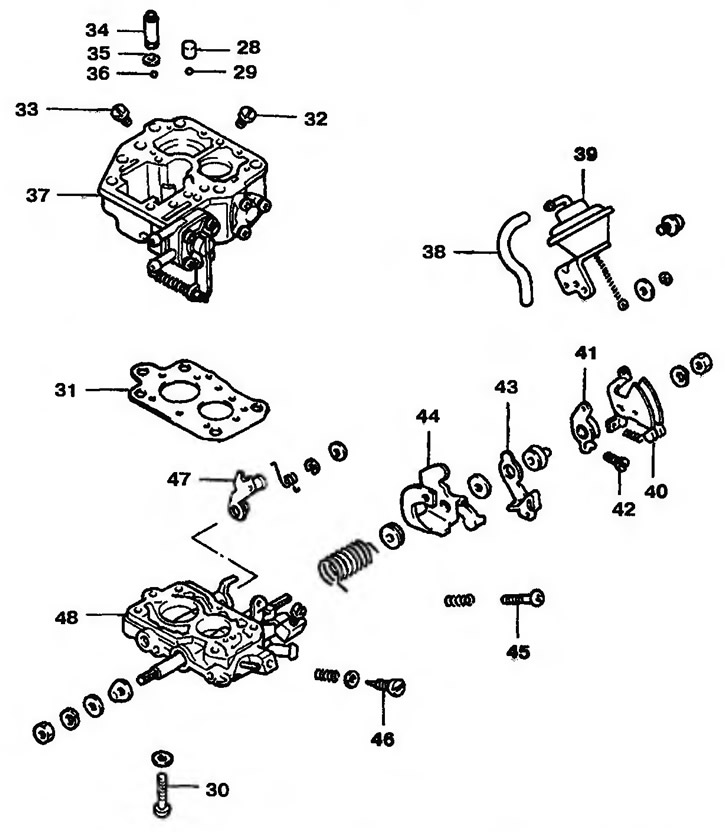

Pic. 10.26a. Carburetor type «D»: 1 - Throttle valve return spring; 2 - Rubber shock absorber; 3 - Return spring bracket; 4 - Damper closing the throttle; 5 - Bolt for fastening the carburetor cover; 6 - Bolt with washer; 7 - Carburetor cover; 8 - Float chamber; 9 - Gasket

Pic. 10.26,. Carb cover: 10 - Pin; 11 - float; 12 - Needle valve; 13 - Needle valve seat; 14, 15, 18, 19 - O-rings; 16 - Retainer; 17 - Electromagnetic shut-off valve; 20 - Bracket; 21 - Thrust air damper; 22 - Choke lever; 23 - Servo valve; 24 - Gasket; 25 - Main air jet; 26 - Idle jet (primary); 27 - Idle jet (secondary)

Pic. 10.26v. Float chamber and throttle body: 28 - Weight; 29, 36 - Balls; 30 - Bolt; 31 - Gasket; 32, 33 - Main jets; 34 - Cork; 35 - O-ring; 37 - Float chamber; 38 - Tube; 39 - Decompression chamber; 40 - Gas lever; 41 - Cam follower; 42 - Adjusting bolt; 43 - Lever; 44 - Bracket; 45 - Adjusting bolt for idle speed; 46 - Adjusting bolt for the amount of combustible mixture; 47 - Secondary lever; 48 - Throttle body

Disassembly

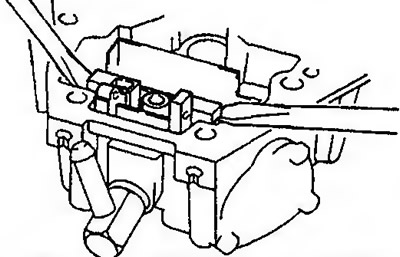

1. Unscrew the five fixing bolts (four - 65 mm long and one - 45 mm) carburetor caps and remove the carburetor body (pic. 10.27). Be sure to remove the bolt that is in the countersunk threaded hole between the primary and secondary threaded mounting holes.

Pic. 10.27. Removing the carburetor cover

2 The carburettor cover has a gasket. Therefore, in order not to apply force, use a screwdriver by inserting it into the gap and prying up the cover to facilitate removal (pic. 10.28).

Pic. 10.28. Use a screwdriver to remove the carburetor cover

3. Using two screwdrivers, pry up on the protruding edges of the valve seat to remove it (pic. 10.29).

Pic. 10.29. Using two screwdrivers, remove the valve seat

Attention! When removing the valve seat, be careful not to damage the carburetor cap.

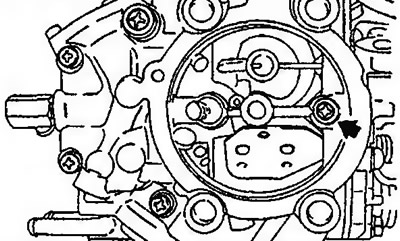

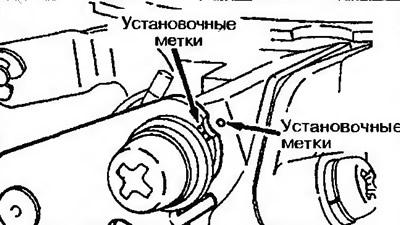

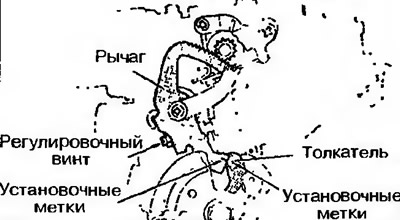

4. Before removing the lever, pay attention to the alignment marks (pic. 10.30).

Pic. 10.30. Marks for setting the lever

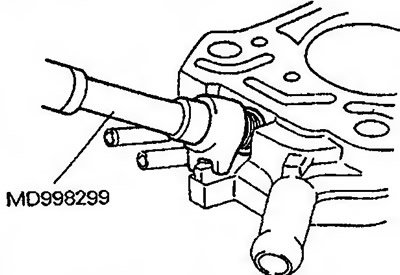

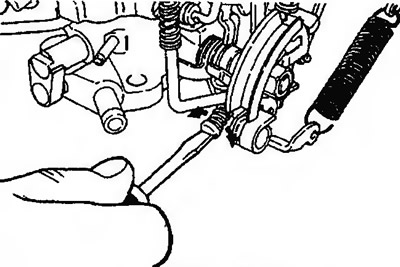

5. Remove the idle speed limiter and air mixture adjusting bolt with the special tool (pic. 10.31).

Pic. 10.31. Remove the idle speed limiter and air mixture adjusting bolt

Examination

6. Check the fuel and air passages for clogs. If they are clogged, wash the clogged parts with detergent or special cleaning liquid (nozzles, etc.) and blow out with compressed air. Do not use wire or metal rods and objects for cleaning.

7. Check diaphragms, o-rings and springs for damage.

8. Check intake fuel filter (located above the needle valve) for blockage and damage.

9. Check float operation. Check the lever and float for deformation and damage.

10. Check the throttle and traction system. If they are stiff, wash the parts and apply a light coat of engine oil to their rollers.

11. Check the carburetor cover and float chamber for damage or cracks.

Installation

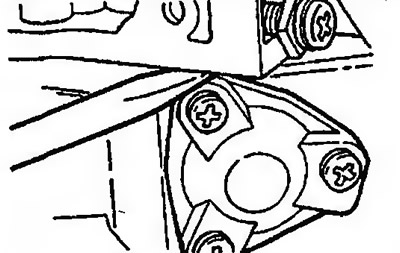

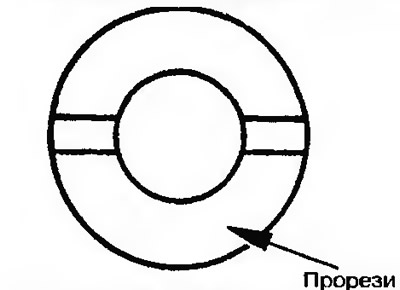

12. Make sure the jet is in the correct position. The applied slots serve to identify the jets (pic. 10.32).

Pic. 10.32. Jet identification slots

Checking and adjusting the throttle valve clearance at high idling speed (type «WITH»)

13. Before checking and adjusting, the carburetor must be placed in a room with a temperature of less than 18°C for at least an hour and then, for at least an hour, in a room with a temperature of about 23°C.

14. Please note: the alignment mark on the lever must match the center punch mark on the pusher (pic. 10.33).

Pic. 10.33. Alignment of the marks on the lever with the punch mark on the pusher

15. Measure the gap between the primary flap and the carburetor wall (pic. 10.34).

Pic. 10.34. Checking the gap between the primary flap and the carburetor wall

16. If the gap does not meet the allowable values, adjust it with the idle speed adjusting bolt (pic. 10.35 am).

Pic. 10.35. Adjustment of a backlash by an adjusting bolt of turns of idling

| Direction of rotation of the adjusting bolt | Gap | Remarks |

| Clockwise | Big | is increasing |

| Counterclock-wise | Small | Decreases |