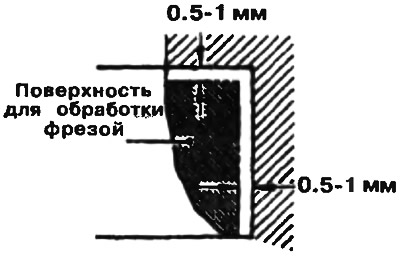

Pic. 4.20. To ease the removal of the saddle, first grind it with a cutter

2. Ream the valve seat hole in the cylinder head to the next oversize (pic. 4.21).

Pic. 4.21. Ream the valve seat hole in the cylinder head to the next oversize

Repair diameter for intake valve seat:

- 0.3mm:

- SOHC-31.80-31.83mm

- DOHC - 34.30-34.33mm

- 0.6mm:

- SOHC-32.10-32.13mm

- DOHC - 34.60-34.63mm

Repair diameter for exhaust valve seat:

- 0.3mm:

- SOHC - 29.30-29.32mm

- DOHC - 30.80-30 83mm

- 0.6mm:

- SOHC - 29.60-29.62mm

- DOHC-31.10-31.13mm

3. Before installing the valve seat, warm up the cylinder head to 250°or cool the valve seat in liquid nitrogen to avoid deformation of the hole in the cylinder head.

4. Machine the valve seat to the required dimensions, namely the required angles and width.

5. Check the clearance between the valve guide and the valve before you start regrinding the valve seat. If necessary, replace the guide bush or valve.

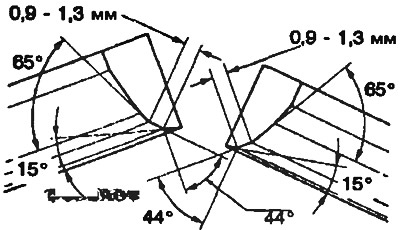

6. Use a special tool or valve seat cutter to match the angles and width of the valve seat to the specified dimensions. Valve seat angles are shown in fig. 4.22.

Pic. 4.22. Valve seat angles

7. After machining the valve seat, lubricate the valve and valve seat with grinding paste. Then check the protrusion of the valve stem.