Normal deformation: 0.05mm. Permissible deformation: 0.1 mm.

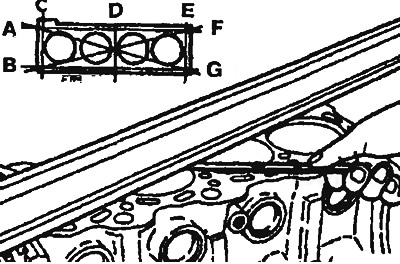

Pic. 4.36. Checking the deformation of the cylinder block

2. Make sure that the surfaces are thoroughly cleaned of gasket residues and other contaminants.

3. If the deformation is more than acceptable, the cylinder block must be replaced.

Maximum lapping: 0.2 mm. Block height (new): 243.5 mm - 4G92, 263.5 mm - 4G93.

4. Check cylinder diameters for scratches and notches (pic. 4.37). If defects are found, grind the cylinders to repair size or replace the cylinder block.

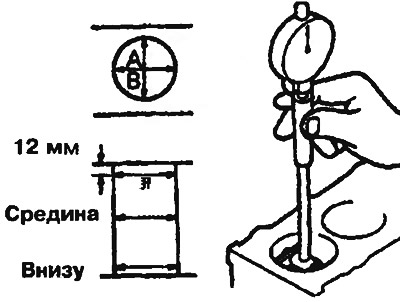

Pic. 4.37. Checking cylinder diameters

5. Using a caliper, check the diameter, ovality and taper of the cylinders. In case of excessive wear, it is recommended to grind the cylinders, and the pistons and piston rings must be replaced with new ones.

Normal inner diameter: 81.00-81.03 mm.

Hole ovality and taper: 0.01 mm.