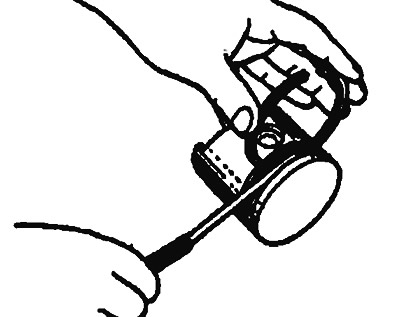

2. Check piston ring clearance (pic. 3.54). If the value is out of range, replace the piston ring, piston, or both.

Pic. 3.54. Checking clearance between piston ring and piston groove

Normal Clearance:

- Top compression ring: 0.03-0.07mm.

- Lower compression ring: 0.02-0.06mm.

Permissible clearance:

- Top compression ring: 0.1 mm.

- Lower compression ring: 0.1 mm.

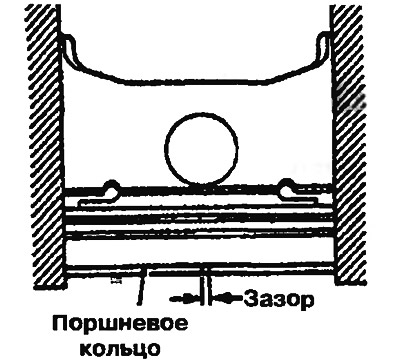

| Options | Nominal value, mm | Limit value, mm |

| Top compression ring | 0.20-0.35 | 0.8 |

| Lower compression ring | 0.35-0.50 | 0.8 |

| Oil scraper ring SOHC 12V, DOHC | 0.20-0.50 | 1.0 |

| Oil scraper ring SOHC 16V | 0.10-0.40 | 1.0 |

3. Install the piston ring in the cylinder bore.

4. Press the piston ring with the piston so that it is at right angles to the bore of the cylinder (pic. 3.55). Then measure the piston ring gap with a gauge.

Pic. 3.55. Checking the end clearance of the piston rings

If the clearance is too large, replace the piston ring.