Table 17.1. Technical data of the 4G1 engine after 2001

| Options | Rated value | |

| Intake air temperature sensor resistance, kOhm | 20°C | 2.3-3.0 |

| 80°С | 0.30-0.42 | |

| Oxygen sensor output voltage, V | 0.6-1.0 | |

| Oxygen sensor resistance at 20°С, Ohm | Front | 4.5-8.0 |

| Rear | 11-18 | |

Engine Diagnostic Trouble Codes

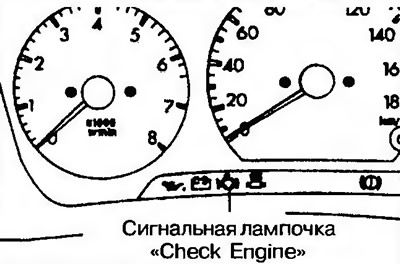

As soon as one of the following points in the MPI fuel injection system fails, the engine warning light comes on (pic. 17.1). If it stays on or comes on when the engine is running, check for trouble codes. Engine Diagnostic Trouble Codes are shown in Table 17.2. To test the functionality, the warning lights come on for five seconds when the ignition is switched on and then go out.

Pic. 17.1. Location of signal light «Check Engine»

Table 17.2. Engine Diagnostic Trouble Codes

| Fault code | Node being diagnosed |

| - | Electronic engine control unit |

| P0105 | vacuum pressure sensor |

| Р0110 | Inlet air temperature sensor |

| Р0115 | coolant temperature sensor |

| P0120 | Throttle position sensor |

| P0125 | Feedback system |

| P0130 | Front oxygen sensor |

| P0135 | Front oxygen sensor heater |

| P0136 | Rear oxygen sensor |

| P0141 | Rear oxygen sensor heater |

| P0170 | Engine power system |

| P0201 | Nozzle 1 |

| P0202 | Nozzle 2 |

| P0203 | Nozzle 3 |

| P0204 | Nozzle 4 |

| P0300 | Interruptions in ignition |

| P0301 | Interruptions in the ignition of cylinder 1 |

| P0302 | Misfiring cylinder 2 |

| P0303 | Misfiring cylinder 3 |

| Р0304 | Misfiring cylinder 4 |

| P0325 | Knock sensor |

| P0335 | Crank angle sensor |

| P0340 | Camshaft Angle Sensor |

| Р0403 | EGR solenoid valve |

| Р0420 | Catalyst |

| Р0421 | Catalyst |

| P0443 | Purge air control solenoid valve |

| P0500 | Vehicle speed sensor |

| P0505 | Idle control system |

| R1610 | Electronic engine lock |

Technology for checking components and assemblies

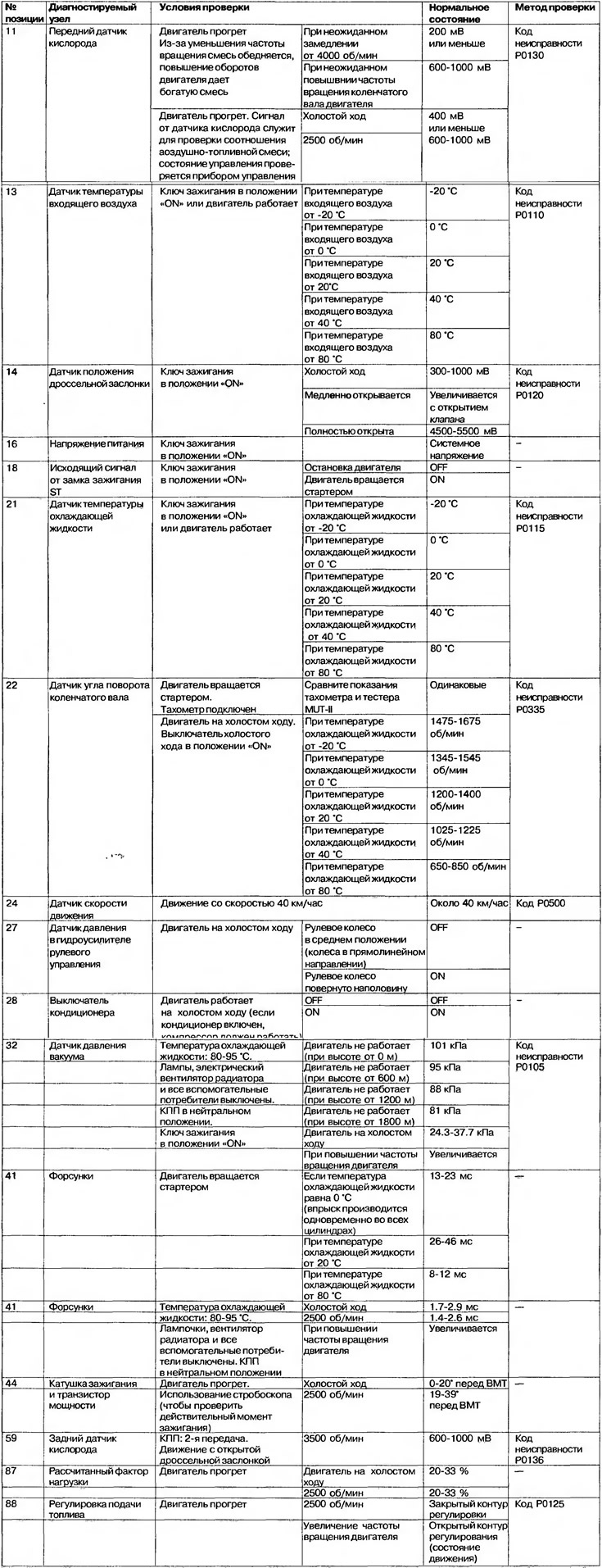

The technology for checking components and assemblies is given in Table 17.3.

Table 17.3. Checking units and assemblies

Checking the engine control unit connector

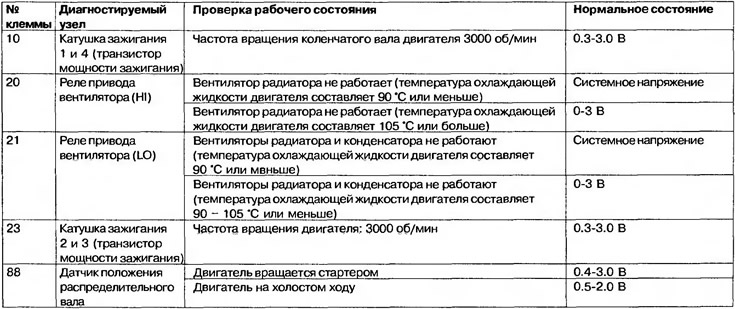

The voltage values at the connector terminals of the engine control unit are shown in Table 17.4.

Table 17.4. Voltage values at the terminals of the connector of the engine control unit

Basic idle speed adjustment

1. The standard idle speed is set by the manufacturer using the speed adjusting bolt (SAS), so no such adjustment is necessary.

2. If the setting is deliberately changed, the idle speed may increase or decrease if the engine is under load, such as from an air conditioner. In this case, you need to make adjustments as described below.

3. Adjustment is carried out only after the performance of the spark plugs, injectors, idle drive with amplifier, compression, etc. has been checked.

4. Connect the MUT-II tester to the diagnostic (16-pole) connector.

5. Start the engine and let it idle.

6. Select item 30 of the Tester Verification Test.

Attention! The ISC stepper motor remains in the initial stage so that the main idle speed can be adjusted.

7. Check the idle speed. Rated value: 750±50 rpm.

Attention! For a new car (with mileage less than 500 km) engine speed can be 20-100 rpm lower, however, adjustment is not necessary in this case. If the engine stalls or the engine speed is too low even though the vehicle has been driven for more than 500 km, the throttle valve is probably clogged and needs to be cleaned.

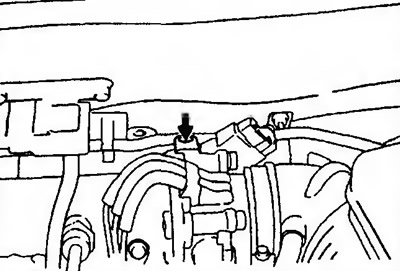

8. If the measured value does not correspond to the nominal value, adjust it with the speed adjusting bolt (SAS) (pic. 17.2).

Pic. 17.2. Location of speed adjusting bolt (SAS)

9. Press the reset button on the MUT-II and exit the ISC stepper motor from test mode.

Attention! If this is not done, the test mode will continue for 27 minutes.

10. Turn off the ignition.

11. Disconnect the MUT-II tester.

12. Start the engine again and let it idle for 10 minutes. Check idle speed.

Nozzle

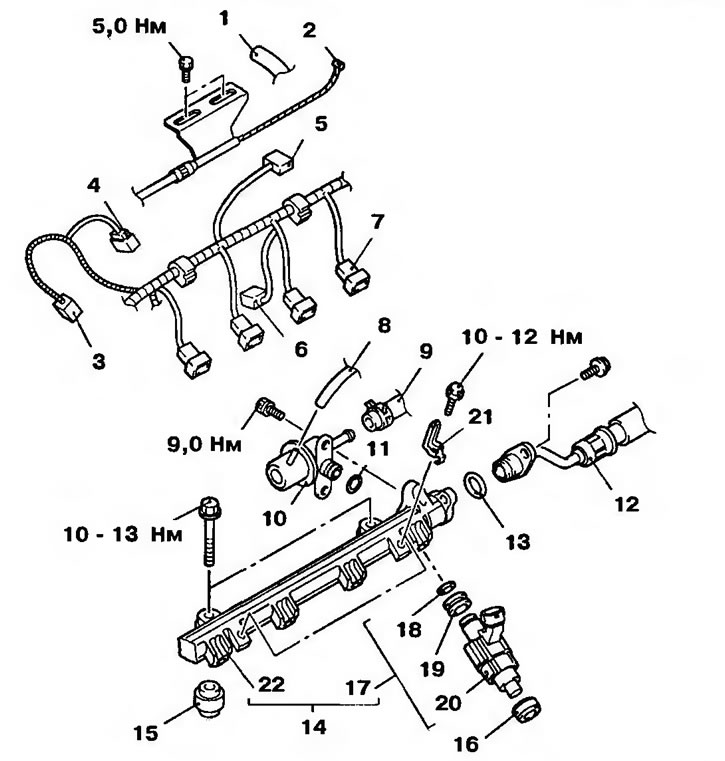

The nozzle is shown in fig. 17.3.

Pic. 17.3. Nozzle: 1 - Crankcase ventilation tube; 2 - Accelerator pedal cable; 3 - Wiring connector for the rear oxygen sensor; 4 - Knock sensor wiring connector; 5 - Vacuum sensor connector; 6 - Wiring connector for the EGR solenoid valve; 7 - Injector wiring connector; 8 - Vacuum tube; 9 - Drain fuel line; 10 - Fuel pressure regulator; 11, 13, 18 - O-rings; 12, 22 - Injection fuel lines; 14 - Fuel distributor with nozzle; 15, 16 - Rubber pads; 17 - Nozzle assembly; 19 - Rubber bushing; 20 - Nozzle; 21 - Bracket for fastening the wiring harness.