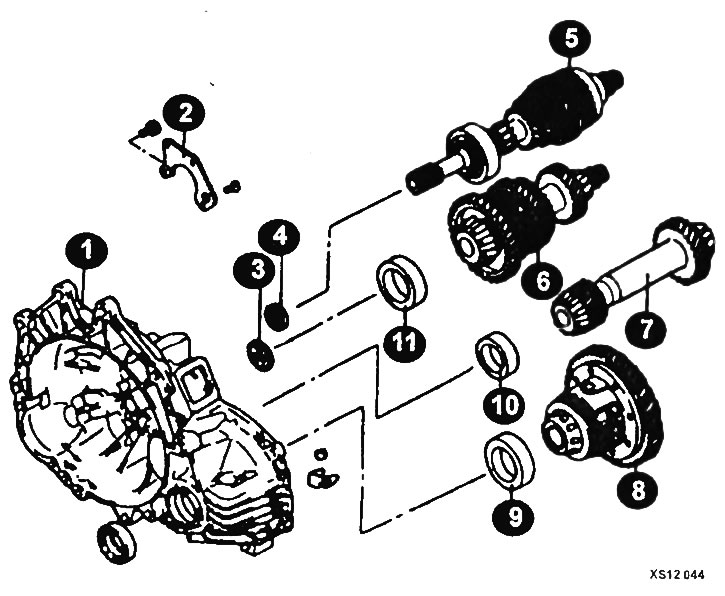

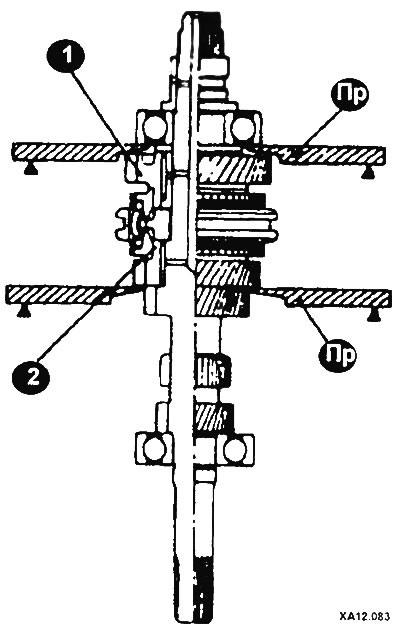

Gearbox shafts

1 _ clutch housing; 2 - bearing holder; 3 - ring; 4 - stuffing box; 5 - input shaft; 6 - intermediate shaft; 7 - secondary shaft; 8 - differential; 9, 10, 11 - outer ring.

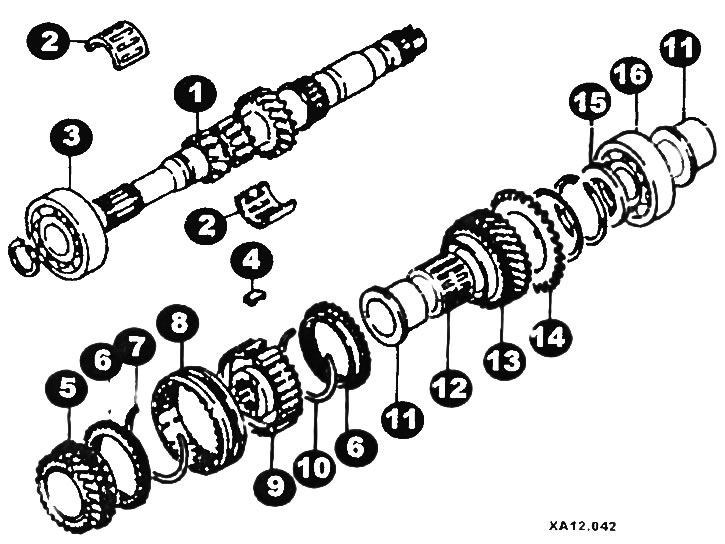

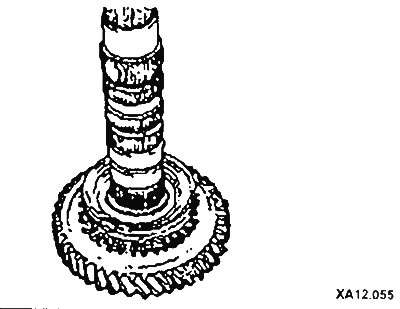

Input shaft elements

1 - input shaft; 2 - needle bearing; 3, 16 - ball bearing; 4 - synchronizer lock; 5 - 3rd gear gear; 6 - synchronizer ring; 7 - synchronizer spring; 8 - sleeve of the synchronizer of the 3rd and 4th gears; 9 - synchronizer hub; 10 - spring; 11 - bearing race; 12 - needle bearing; 13 - gear wheel of the 4th gear; 14 - driven gear; 13 - spacer sleeve.

Disassembly

Remove the lock washer and front ball bearing.

Remove the bearing race.

Remove the bearing.

Remove the spacer, lock washer, spring and driven gear.

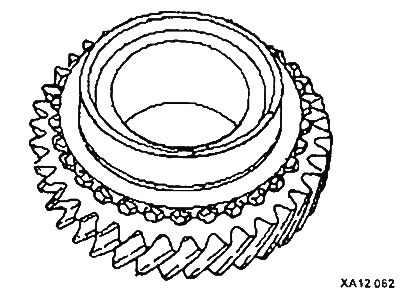

Remove the 4th gear, needle bearing and bushing.

Remove the synchronizer ring and sleeve.

Remove bushings and synchronizer pins for 3rd and 4th gears.

Remove hubs and synchronizer rings for 3rd and 4th gears.

Remove the 3rd gear and needle bearing.

Check the condition of the external surface of the input shaft at the needle bearing installation site, as well as the condition of the splines of the input shaft.

Align the needle bearing with the shaft or bearing sleeve and gear and check for smooth rotation.

Place the synchronizer ring against the clutch gear and check the clearance. It should be 0.5 mm.

Check the teeth of the bevel gear and clutch gear.

Check the synchronizer cone.

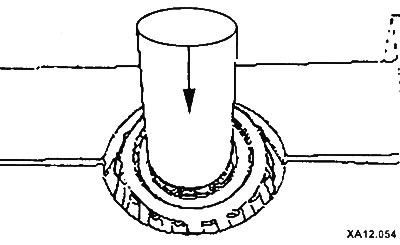

Assembly

Assembly is carried out in the reverse order, taking into account the following:

During the assembly of the installation of gears 3rd (2) and 4th (1) gears, use tools.

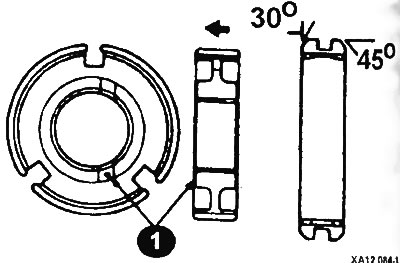

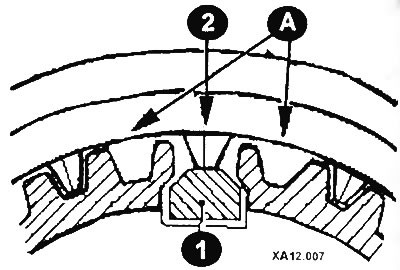

Align match marks (1) when assembling the synchronizer of 3rd and 4th gears (pic. XA12.048-1).

Install the synchronizer sleeve on the hub so that the tooth (2), located between two areas without teeth (A) touched the synchronizer cracker (1).

Springs and crackers are installed in accordance with the figure.

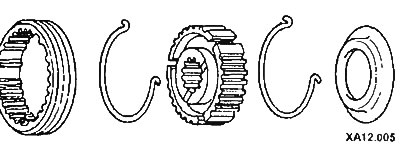

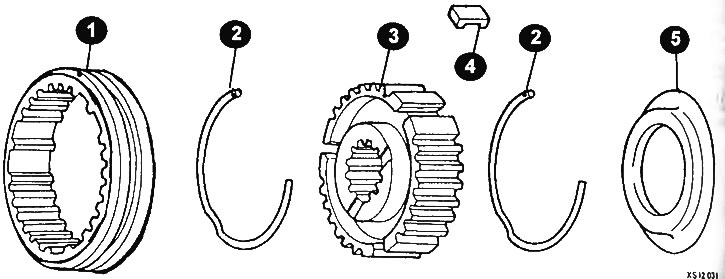

5th gear synchronizer hub elements

1 - bushing; 2 - spring; 3 - hub; 4 - cracker; 5 - puck.