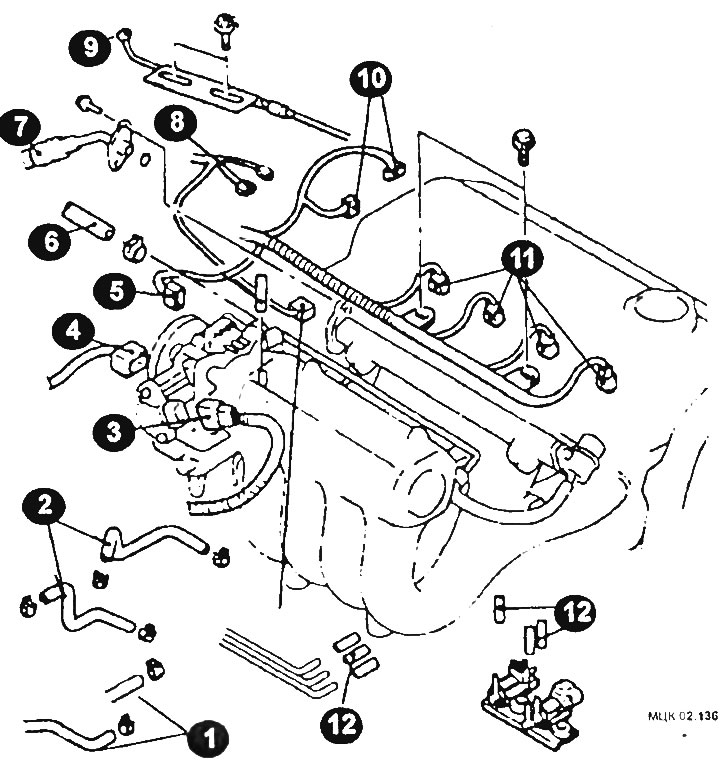

External electrical / hydraulic elements of the 4G93 engine

1 - heater hoses; 2 - coolant hoses; 3 - throttle position sensor connector; 4 - idle speed controller connector; 5 - accelerator pedal position sensor connector; 6 - fuel return hose; 7 - high pressure fuel hose sleeve; 8 - coolant temperature sensor connector; 9 - accelerator pedal cable connection; 10 - distributor connector; 11 - nozzle connector; 12 - connection of vacuum hoses.

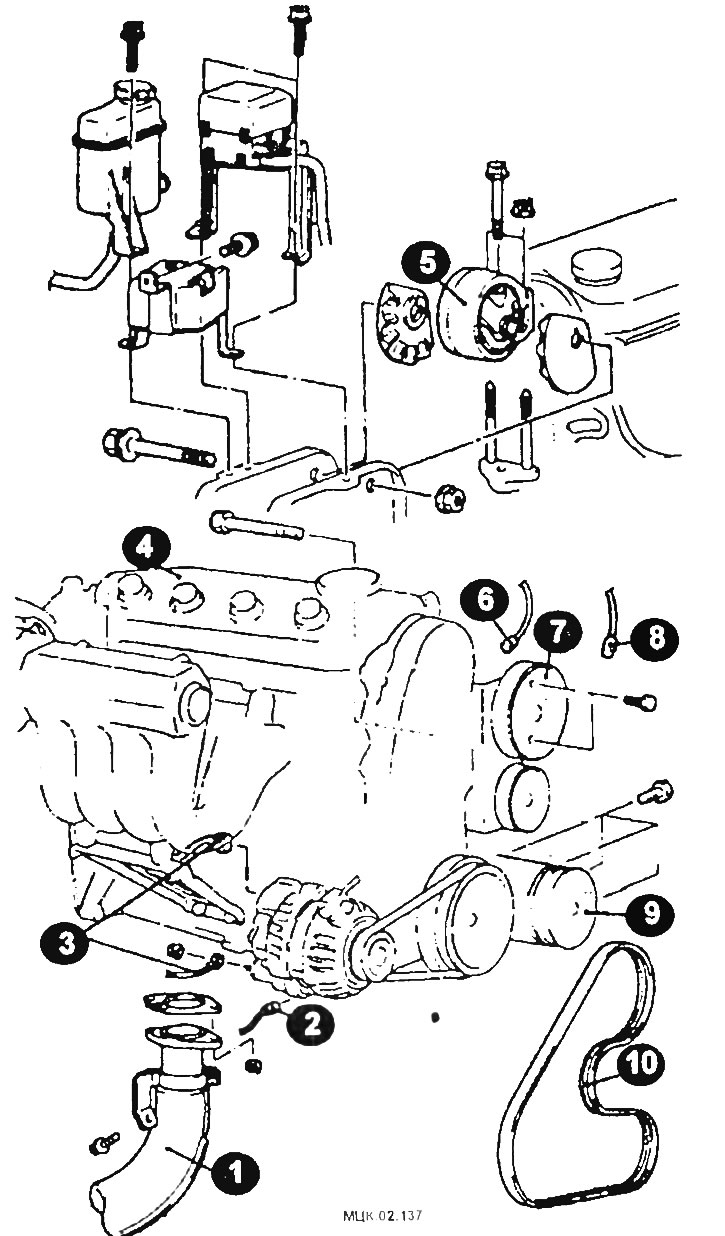

External elements of the 4G93 engine

1 - exhaust pipe of the exhaust system; 2 - connector of the oil pressure sensor-switch; 3 - generator connector; 4 - engine cylinder head cover; 5 - engine support; 6 - connector for the fluid pressure sensor in the power steering; 7 - fastening of the pump of the amplifier of a steering; 8 - air conditioner compressor connector; 9 - air conditioner compressor; 10 - drive belt for power steering and air conditioning compressor.

Removing

Disconnect the ground wire from the battery.

Relieve fuel pressure in the fuel system.

Remove the hood.

Drain the coolant from the engine cooling system.

Remove the gearbox.

Remove the radiator.

Disconnect the gas pedal cable.

Disconnect the connectors of the throttle position sensor, idle speed control, gas pedal position sensor (if there), knock sensor, coolant temperature sensor of the distributor and injectors.

Remove the fuel return hose.

Disconnect the high pressure fuel hose and gasket.

Disconnect the brake booster vacuum hose.

Disconnect the coolant hoses.

Disconnect heater hoses.

Disconnect electrical connectors.

After loosening the tension, remove the power steering pump and air conditioning compressor drive belt.

Remove the power steering pump without disconnecting the hoses connected to it.

Tie the removed pump with wire on the car body.

After disconnecting the air conditioning compressor connector, remove the compressor from its bracket without disconnecting the connected hoses.

Tie the removed compressor to the car body with wire.

Disconnect a reception pipe of system of release of the fulfilled gases.

Place a jack under the engine.

Attach the engine to the lifting device. After slightly lifting the engine with a jack to unload the support from the weight of the engine, remove the engine support bracket.

Check that all wires, hoses, etc. are disconnected from the engine, and then slowly remove the engine upwards from the engine compartment.

Installation

The engine is installed in the reverse order, taking into account the following:

When installing the high pressure fuel hose, lubricate the O-ring with a small amount of clean engine oil.