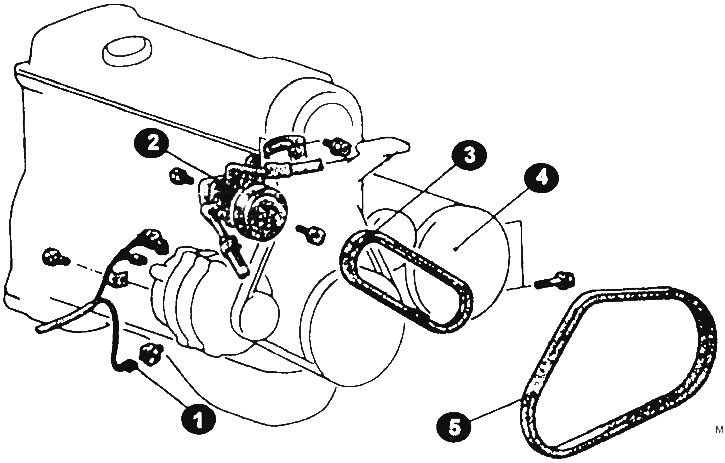

External elements of the engine

1 - wire harness connectors; 2 - power steering pump; 3 - steering pump drive belt; 4 - air conditioner compressor; 5 - V-belt.

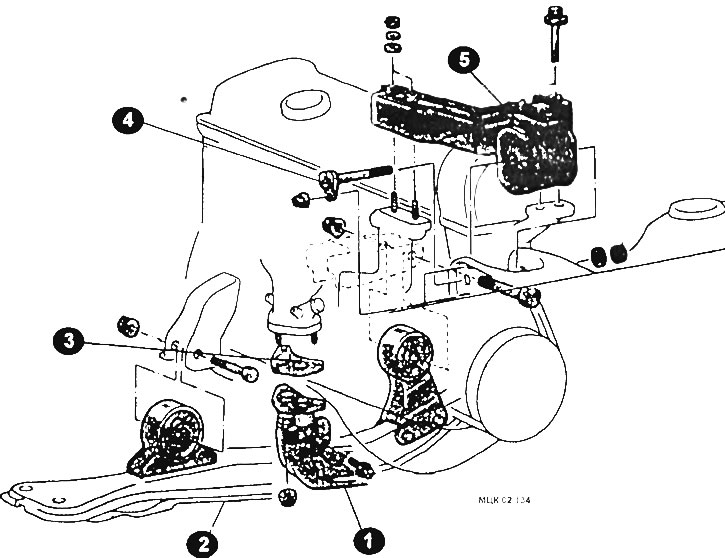

engine mounts

1 - exhaust pipe of the exhaust system; 2 - longitudinal beam; 3 - gasket; 4 - fastening bolt; 5 - upper engine support.

WARNING: Gasoline is extremely flammable, so special care must be taken when working on any part of the fuel system. Do not smoke or allow open flame sources in the work area. If gasoline comes into contact with skin, wash immediately with plenty of soap and water.

Wear safety goggles and have a fire extinguisher handy when working on any component of the fuel system.

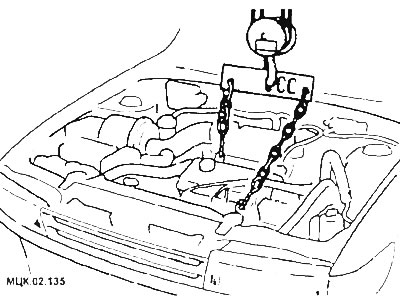

The engine without gearbox is lifted up with a crane.

Disconnect the ground wire from the battery. Disconnect the battery only when the ignition is off. This will provide protection from damage.

Open the engine compartment hood and drain the coolant.

Remove the gearbox.

Remove the radiator.

Drain the engine oil into a suitable container.

Remove the air filter; Disconnect the warm air, low pressure and crankcase ventilation hoses.

Disconnect the throttle cable and move it aside.

Disconnect the heater hoses by first pushing back the clamps.

Disconnect the low pressure hose of the brake booster from the suction pipe.

Carburetor engine: Disconnect the supply hose from the fuel pump and the fuel return hose from the carburetor, after releasing the clamps.

fuel injected engine (MPI): remove the connecting plate of the fuel supply hose from the distribution pipe; remove the sealing ring, when installing, replace the ring with a new one, but first you need to relieve pressure.

Attach a chain or cable to the eyes.

Slowly raise the engine just enough to relieve the engine mounts.

Unscrew the engine beam.

Remove the lower engine mounts.

Check if all wires and hoses are disconnected from the engine.

Carefully lift the engine with a crane so as not to damage the body.

Installation

Check all engine mounts, oil and fuel hoses for cracks or other damage and replace if necessary.

Check the clutch disc. In case of significant wear and high mileage, replace the clutch as a set. If release bearing noise is observed, replace the bearing, check the release bearing for wear.

Clean and lightly coat the clutch release bearing and drive shaft splines.

Carefully insert the engine into the engine compartment. Be careful not to damage the drive shaft.

Place the engine on stands and secure.

Detach the lifting device.

Attach the muffler pipe with a new gasket to the exhaust manifold with new nuts.

Install the A/C compressor and then the power steering pump.

Install the V-belt.

Connect the connector to the oil pressure switch.

Connect the electrical wires to the generator.

Lower the car.

Fit all low pressure hoses and secure with clamps.

Connect all electrical wires to the engine.

For carburetor models, connect the inlet and outlet fuel hoses to the fuel pump and to the carburetor and secure with clamps.

Injection engine: Connect and secure the fuel supply pipe with a new gasket.

Connect the throttle cable to the throttle element and to the heel.

Connect the low pressure hose from the hydraulic booster of the brake system to the exhaust manifold and secure with a clamp, put on and secure the heater hoses with clamps.

Install the radiator and then the gearbox.

Install the engine compartment hood in its original position.

Fill in engine oil and check the level in the engine and gearbox, top up if necessary.

Check the concentration of antifreeze in the coolant and top up.

Adjust the throttle cable.

Connect ground wire to battery.

Warm up the engine to normal coolant operating temperature.

Check the tightness of all hose connections.

Make sure the ignition timing is set correctly and check the engine at idle.

Set the clock.