Lay the cylinder head on a workbench with two pieces of wood underneath.

Clean all valves from carbon deposits.

Apply coarse carborundum paste to the bevel of the valve seat.

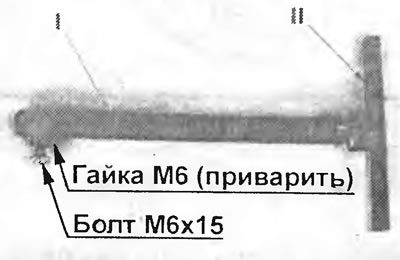

Clamping the valve in the instrument, press the valve disc against the seat, occasionally lifting the valve to redistribute the paste.

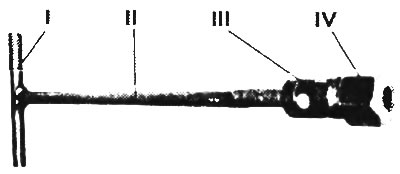

Valve Lapping Tool with Collet

General view of the device

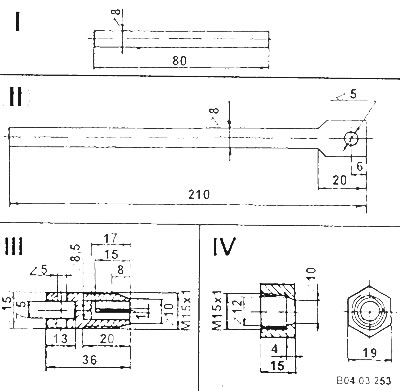

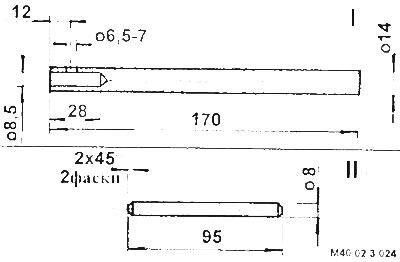

Fixture detail

Valve lapping tool, which you can make yourself

General view of the device

Fixture detail

When a matte line appears on the valve and seat, rinse off the remaining paste and repeat the same procedure with fine carborundum paste.

When a continuous light gray matte ring 0.9-1.3 mm wide appears on the valve and seat, lapping is complete.

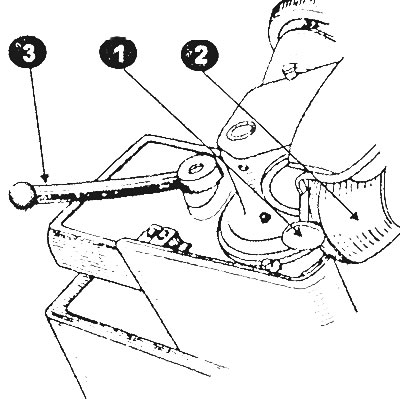

A grinding machine can be used to grind the working chamfers of the valves. To do this, it is necessary to install a valve on the grinding machine and fix the movable support so as to obtain the required chamfer angle.

1 - valve; 2 - grinding wheel; 3 - lever.

Carefully clean off all traces of abrasive, being especially careful not to get it into the valve guides. Wipe the valves and valve seats with a rag soaked in kerosene, then with a clean rag and finally, if possible, blow with compressed air.