CAUTION: Install new piston rings each time the engine is disassembled.

Using ring installers, carefully remove the old rings from the pistons. Be careful not to scratch or damage the pistons.

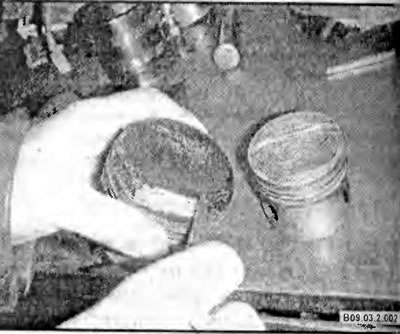

Clean all traces of carbon from the top of the piston using a hand wire brush or sandpaper. With strong soot, you can use a piece of the old piston ring.

Never use a wire brush mounted on a drill, because it can damage the piston, which is made of soft material.

Using a piece of the old piston ring, clean the carbon deposits in the ring grooves. Only scrape off carbon deposits and do not remove metal or scratch the sides of the grooves.

After you have cleaned off the carbon deposits, clean the pistons with connecting rods with a solvent and dry them. Make sure the oil return holes on the sides of the ring grooves are clean

If the pistons and cylinder walls are not too worn and damaged, and if the cylinders have not been bored, old pistons can be used. Normal piston wear shows up as vertical wear streaks on the piston bearing surfaces and a slight slack in the top ring in its groove.

Look for nicks and scratches on the skirt bearing surfaces, in the piston pin bore, and for burnt areas on the edge of the head.

If the skirt is scratched or frayed, the engine may suffer from overheating and or abnormal combustion resulting in excessively high operating temperatures. These pistons should be replaced. Lubrication and cooling systems must be carefully checked. A hole in the piston head indicates abnormal combustion (premature (early) ignition). Burned areas on the edge of the head are usually indicative of detonation. If any of the listed problems occur, their causes must be eliminated, otherwise the damage will occur again. Causes may include intake air leaks, incorrect air-fuel mixture, incorrect ignition timing, and improper operation of the exhaust gas recirculation system.

A typical burnt piston resulting from abnormal combustion

Piston corrosion in the form of small pits indicates that coolant is leaking into the combustion chamber and or crankcase. This fault must also be corrected.

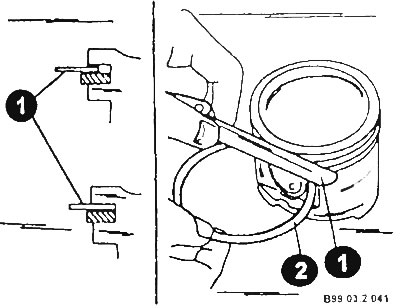

Measure the piston ring backlash by placing a new ring in each groove (2) and inserting a probe plate next to it (1). Measure the clearance at three or four points along the diameter of each groove. Make sure you use the right ring - they are different. If the side clearance is greater than the allowable value, the piston must be replaced.

Check the clearance between the piston and the cylinder wall by measuring the cylinder bore diameter and the piston diameter. Measure the piston diameter across the skirt, coaxially and at an angle of 90°to the piston pin. The clearance is defined as the difference between the diameters of the bore of the cylinder and the piston. If the clearance is greater than the allowable bore of the cylinders, bore out and use new pistons and rings.

Check the clearance between the piston and connecting rod by moving them in opposite directions. Any noticeable play means that there is excess wear that must be corrected. The pistons, together with the connecting rod, should be machined and new oversize rings installed.

Check the connecting rod for warping. To do this, firmly fix the connecting rod on the fixture and measure the deviation of the connecting rod from the plane. In case of deviation, the connecting rod must be replaced by selecting it by weight.

ATTENTION: The difference in weight in a set of connecting rods should not exceed 4 grams.

Check the connecting rods for cracks or other damage. Periodically remove the connecting rod caps, pull out the old bearing shells, wipe the surface of the bearings in the connecting rods and caps clean and check for scratches, nicks, etc. After checking the connecting rods, replace the old bearing shells, reinstall the caps and tighten the nuts with your fingers.