Lay out new pistons and rings with connecting rods so that the gap between the ends of the rings will be checked on those pistons and in those cylinders where these rings will be installed.

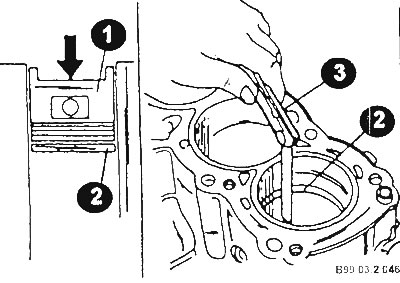

Insert the top (first) ring (2) into the first cylinder and place it perpendicular to the walls, pushing the piston (1). The ring should be located near the extreme point of the ring travel.

To measure the gap between the ends of the rings, insert probe plates into the gap (3) different thicknesses until a feeler gauge is found equal to the width of the gap. The feeler gauge should slide between the ends of the ring with little effort. Compare the resulting gap value with the technical data.

The required clearance for all rings is 0.3±0.15 mm. If the gap is more or less than normal, check again if you took the correct ring size.

If the gap is too small, it must be increased, otherwise the ends of the rings may touch each other while the engine is running, which can cause serious damage. The gap can be increased by carefully filing the ends of the rings with a fine file. Hold the file in a vise and slowly move the ends of the rings along the file so that the metal is removed from the outside to the inside. Sawing is done at a right angle, and all burrs must be removed before assembly.

Repeat the above procedure for all remaining rings.

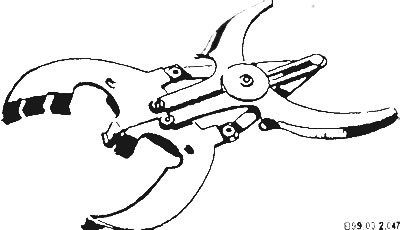

After checking the gap between the ends of the rings, the rings can be installed on the pistons using a tool.

Piston ring installer/remover

The oil scraper ring is usually installed first (lowest).

- Install mesh atomizer (1) oil scraper ring into the piston groove.

- Install the top ring (2) oil scraper ring.

- Install the bottom ring (3) oil scraper ring.

ATTENTION: The device for installation of elements of an oil scraper ring is not required.

ATTENTION: If an old oil scraper ring is installed, the ring elements must be thoroughly cleaned.

After the oil scraper ring is installed, make sure that the ring rotates easily in the groove.

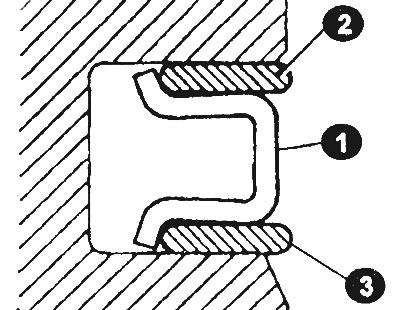

The second compression ring is installed next (average).

ATTENTION: Do not confuse the upper and middle rings - they have a different cross section.

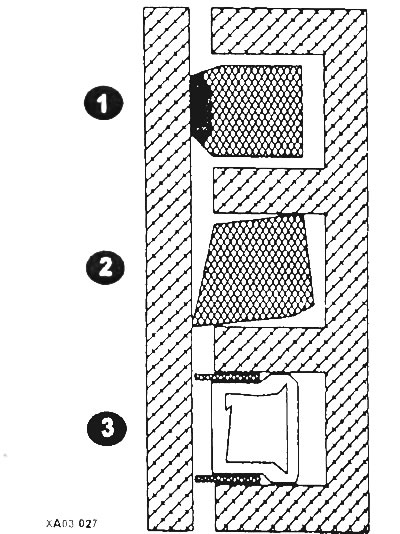

The correct arrangement of the rings in the piston grooves

1 - top compression ring; 2 - lower compression ring; 3 - oil scraper ring.

Using a ring installer, insert the ring into the middle groove of the piston. Do not stretch the ring more than is necessary for the piston to pass through it.

Install the top in the same way (first) ring.

Piston ring installation - simplified installation method

Check that the piston ring grooves and oil passages are thoroughly cleaned. Always install rings by sliding them from the top of the piston.

The easiest way to install rings is to use a flat feeler gauge (thickness 0.3-0.5 mm). The probe is pressed against the piston and the ring slides over it. This operation is inverse to the operation of removing the rings.

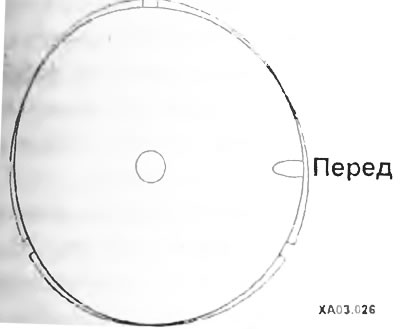

After installing the rings, rotate them so that their locks are located at 120°.