Clean the rear sides of the new main bearing inserts and place the halves with the oil hole on the main bearing seats in the cylinder block.

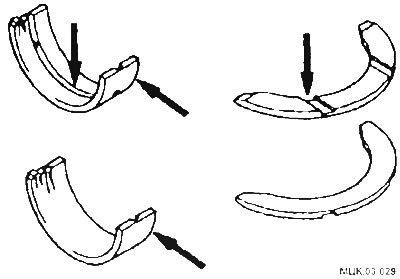

Install the other halves from each set into their respective bearing caps. Make sure that the key of each liner fits into the cutout in the cylinder block or cover.

CAUTION: Do not hammer in the earbuds or scratch the front surfaces of the earbuds. So far, no lubrication is required.

Wipe the seating surfaces of the liners in the block and the crankshaft main journals with a clean cloth. Check or clean the oil holes in the crankshaft.

Carefully place the crankshaft on the main bearings. Before finally installing the crankshaft, it is necessary to check the oil clearance of the main bearings, which is determined by simply measuring the bore diameters or using a special measuring plastic.

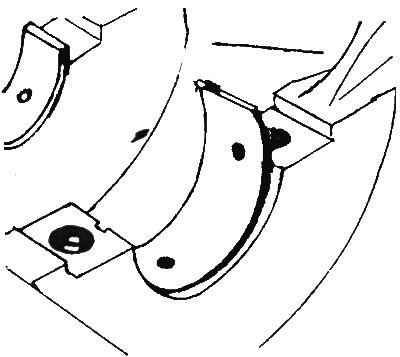

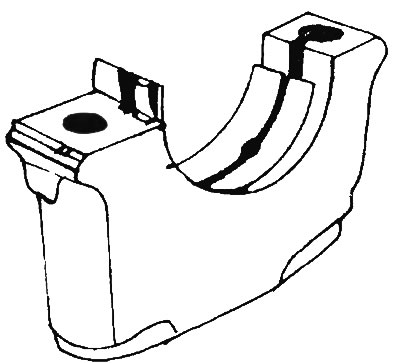

Peel off a few pieces of suitable size plastic to measure the gap (they should be slightly shorter than the width of the main bearings) and place one piece on each main shaft parallel to its axis.

Clean the surface of the bearings in the caps and reinstall the caps. Don't move the plastic. Apply some oil to the threads of the bolts.

Tighten the main bearing cap bolts in three steps to the correct torque. Do not turn the crankshaft during this operation.

Loosen the bolts and carefully remove the bearing caps.

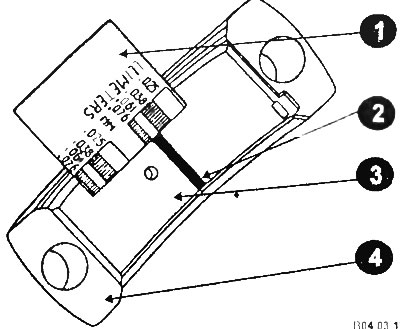

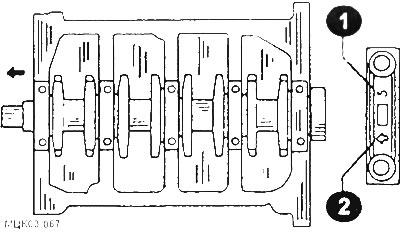

Compare the width of the crushed plastic on each neck to the scale printed on the plastic bag, and determine the gap. Compare your results with the technical data.

1 - scale; 2 - plastic wire; 3 - insert; 4 - contact surface of the cover.

ATTENTION: The scales on the plastic bag are in mm and inches, do not confuse them.

If the gap is not correct, the bearings may have been the wrong size. Before deciding whether to replace the liners, check for dirt and oil between the liner and the cover. If one end of the gap gauge is significantly wider than the other, the neck may be tapered.

Carefully clean all traces of plastic for measuring clearances from the journals and bearings. Do not scratch the bearing surfaces.

The liners are selected according to the marks and color markings applied on the crankshaft and the lower head of the connecting rod.

Tags 4-cylinder engine

crankshaft marks

Cylinder block marks

Tags 6-cylinder engine

Connecting rod identification marks (6A12 engine)

Final installation of the crankshaft

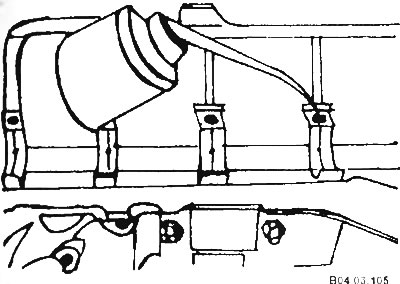

Carefully pull the crankshaft out of the engine. Clean the surface of the bearings in the block, then apply a uniform coat of engine oil to them.

Lubricate the surfaces of the crankshaft in contact with the oil seals with clean engine oil.

Make sure the crankshaft journals are clean, then put the crankshaft in place in the cylinder block.

Clean the bearing surfaces in the caps and apply grease to them.

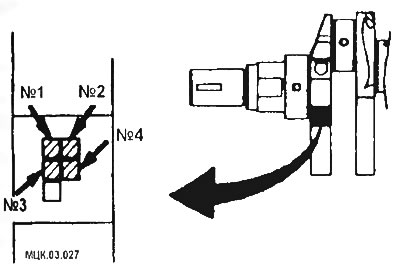

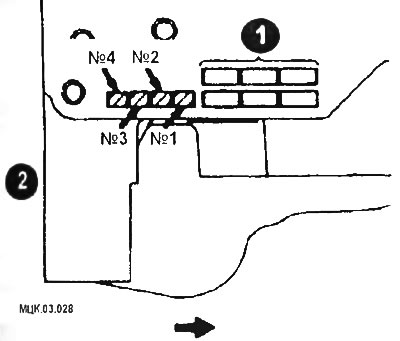

Replace the covers so that the marks on the covers are on the side of the generator.

Tags of covers of main bearings of a cranked shaft

1 - cover number; 2 - an arrow pointing to the front of the engine.

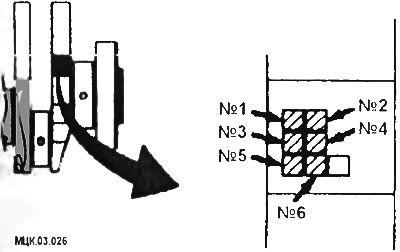

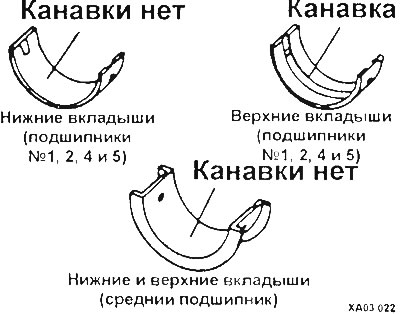

ATTENTION: Before installing the covers, check the liners in the beds of the covers again. The bushing of the 3rd bearing should be without an oil groove, while the rest should have it.

Inserts for 4-cylinder engines

Inserts for 6-cylinder engines

Apply a light coat of oil to the threads and underside of the bolt heads, then install them.

Tighten the nuts of all main bearing caps except the number 3 thrust bearing cap to the specified torque. Drive the shaft back and forth to seat the thrust bearing shells, and then tighten the number 3 cap nuts to the correct torque.

Measure the shaft play with feeler gauges or an indicator (see above).

Rotate the crankshaft several times by hand and check if it is jamming.

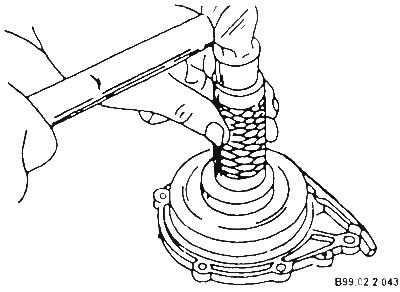

Using a mandrel, press the oil seal into the rear cover of the cylinder block.

Using a drift, put on the rear cover of the cylinder block (stuffing box) onto the crankshaft journal and secure the cover to the block.