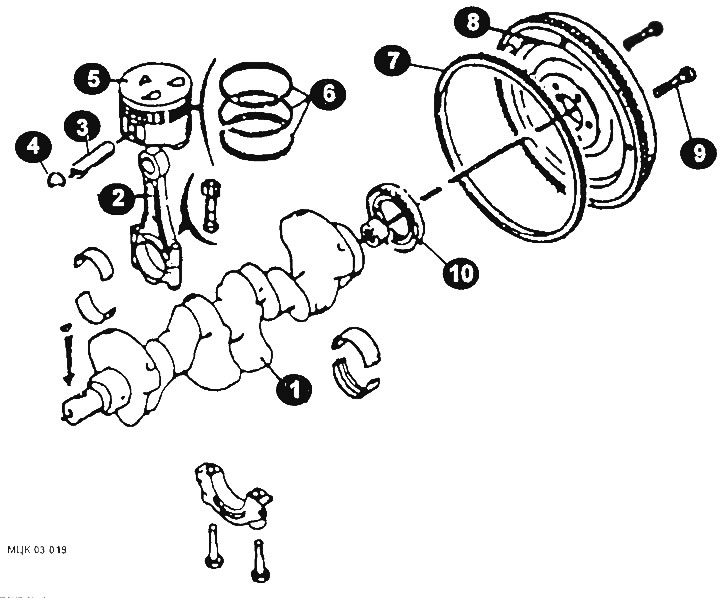

Typical elements of a crank mechanism (KShM) 4-cylinder engine

1 - crankshaft; 2 - connecting rod; 3 - finger; 4 - retaining ring; 5 - piston; 6 - piston rings; 7 - gear ring of the flywheel; 8 - flywheel; 9 - bolts; 10 - crankshaft rear oil seal.

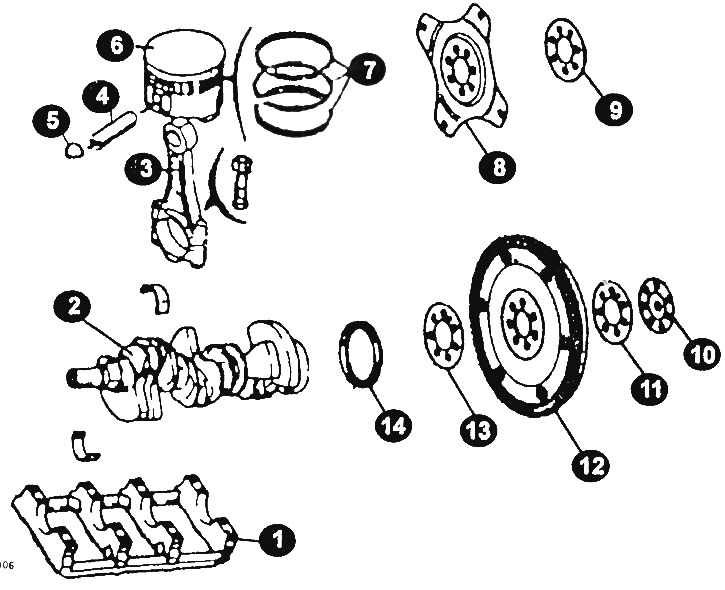

Elements of the crank mechanism of a 6-cylinder engine (6А12)

1 - cover of main bearings; 2 - crankshaft; 3 - connecting rod; 4 - finger; 3 - retaining ring; 6 - piston; rings; 8 - drive disk of an automatic transmission; 9 - automatic transmission disc; 10, 11, 13 - disk; 12 - flywheel; 14 - rear oil seal.

ATTENTION: Before removing the crankshaft, the following must be removed: flywheel, oil sump, oil pump, pistons with connecting rods, rear cover of the engine block.

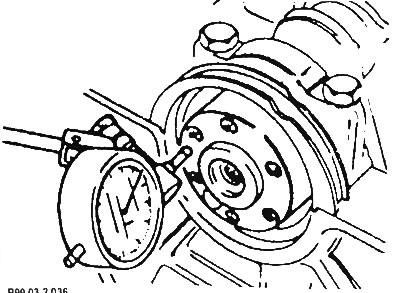

Before removing the crankshaft, check the end play of the shaft. Install the gauge with the indicator coaxially with the shaft and rest the gauge rod against the end or the crank.

Press the shaft all the way back and set the indicator to zero. Then press the shaft all the way forward, write down the arrow reading, which is equal to the backlash. If the play is greater than the allowable value, check the shaft thrust bearings for wear. If wear is found, the clearance can be reduced by installing new thrust bearings.

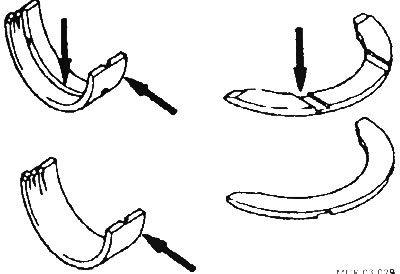

Main bearings (liners) crankshaft four-cylinder engine

WARNING: On a six-cylinder engine, the middle (second) The bearing has a design with two thrust half rings.

Main bearings (liners) crankshaft 6-cylinder engine

Backlash can also be measured using feeler gauges. Press the shaft all the way forward. Insert feeler plates between the shaft and the front surface of the knee bearing.

Check the markings on the main bearings. They must be numbered sequentially from the front of the engine to the rear. If there are no marks, mark with a center punch. Often there is an arrow on the lids that points forward. If not, draw an arrow with paint before removing the covers. Loosen the cap nuts in 1/4 turn increments until they can be removed by hand.

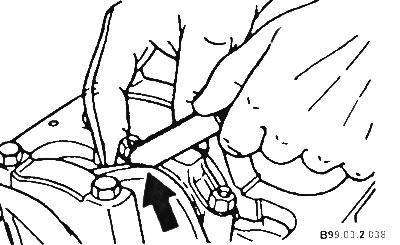

Tap the covers gently with a soft-faced hammer, then remove them from the cylinder block. If necessary, use the bolts as levers to remove the covers. Try not to drop the bearing shells.

Carefully pull the crankshaft out of the engine. Put the bearing shells in place, install the bearing caps and tighten the bolts by hand.