ATTENTION: The procedure for disassembling the cylinder head is the same for all engines, with the exception of minor differences.

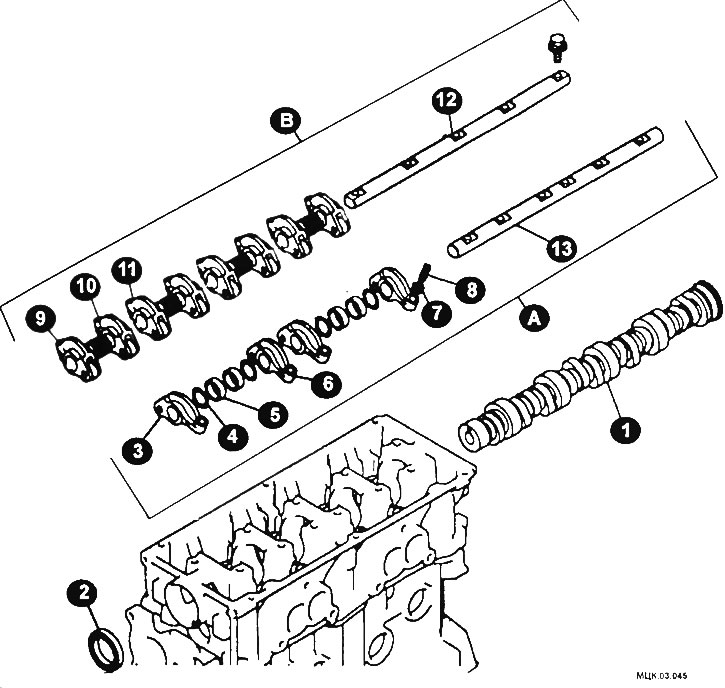

Camshaft elements of 4-cylinder 12-valve SOHC engines

A - elements of exhaust valves; B - elements of intake valves; 1 - camshaft; 2 - stuffing box; 3, 6 - exhaust valve rocker; 4 - adjusting washer; 3 - spacer sleeve; 7 - nut; 8 - adjusting screw; 9, 11 - inlet valve rocker; 10 - spring; 12, 13 - axis of the rocker arms.

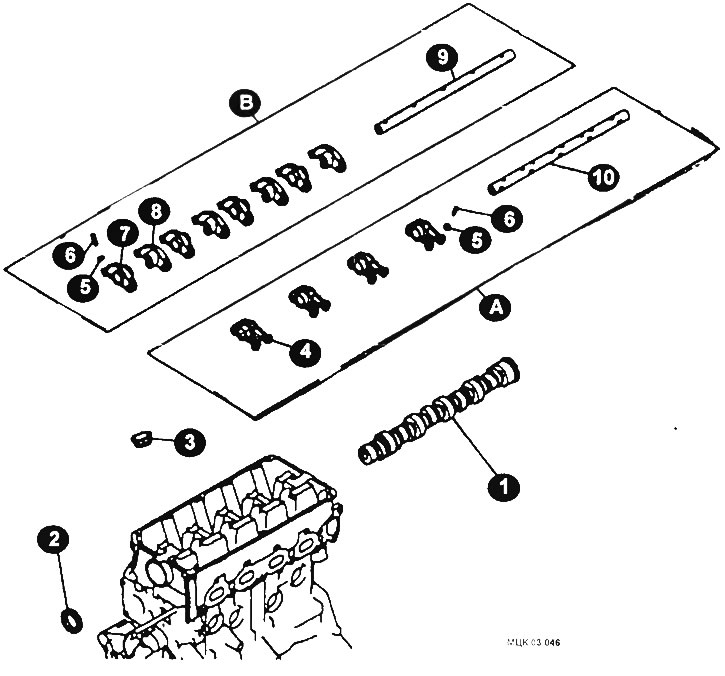

Camshaft elements of 4-cylinder 16-valve SOHC engines (early car models)

A - elements of exhaust valves; B - elements of intake valves; 1 - camshaft; 2 - camshaft seal; 3 - seal; 4 - exhaust valve rocker; 5 - nut; 6 - adjusting screw; 7, 8 - inlet valve rockers; 9, 10 - rocker axles.

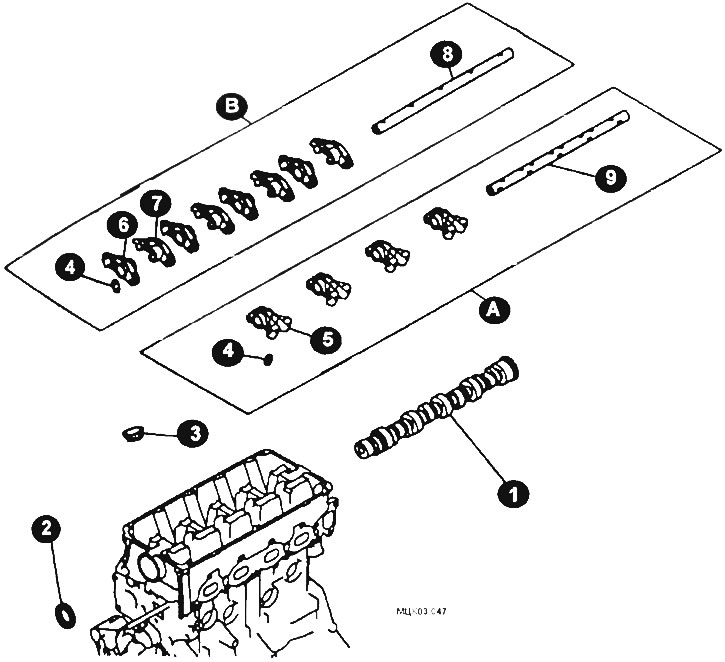

Camshaft elements of 4-cylinder 16-valve SOHC engines (late car models)

A - elements of exhaust valves; B - elements of intake valves; 1 - camshaft; 2 - camshaft seal; 3 - seal; 4 - hydraulic pusher; 5 - exhaust valve rocker; 6, 7 - inlet valve rocker; 8, 9 - rocker axes.

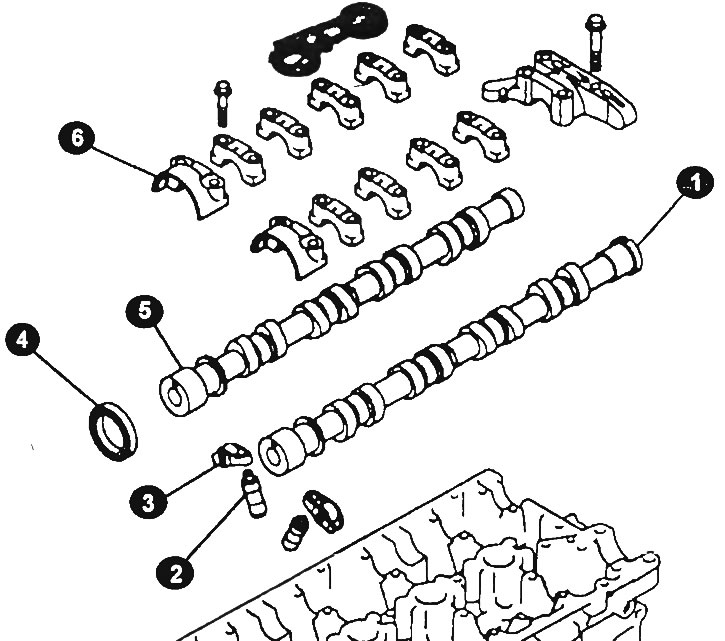

Camshaft elements of 4-cylinder 16-valve DOHC engines

1, 5 - camshaft; 2 - hydraulic pusher; 3 - rocker; 4 - camshaft seal; 6 - camshaft bearing cover.

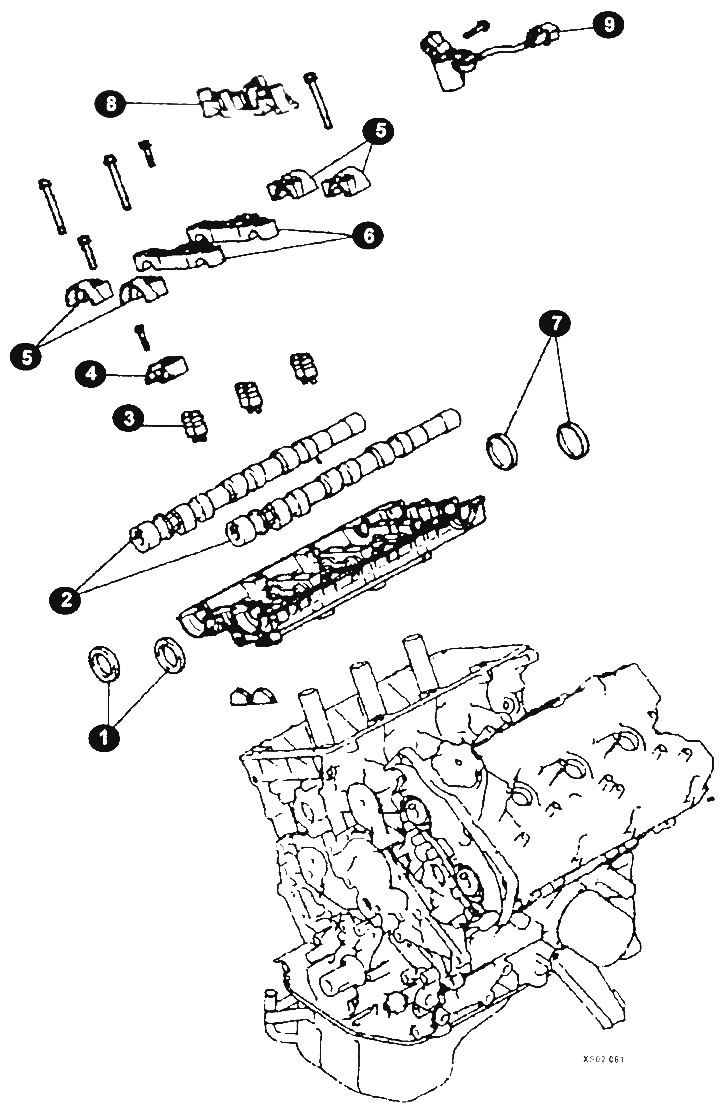

Elements of the camshaft of a 6-cylinder engine 6А12 (DOHC)

1, 7 - glands; 2 - camshafts; 3 - hydraulic pushers; 4, 5, 6 - covers; 8 - oil pressure sensor cover; 9 - oil pressure sensor.

Dismantling of a head of cylinders includes removal of all elements.

Label all parts and store separately so that they can be placed in their original positions when installed.

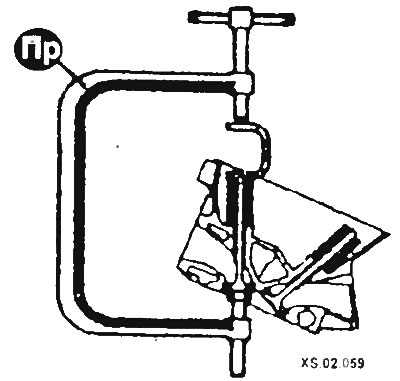

Mount the cylinder head on a table or in a vise.

If not removed, remove the coolant temperature gauge sensor and oil pressure indicator light sensor.

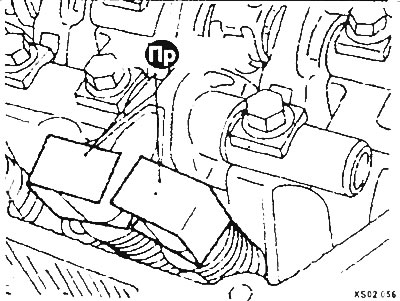

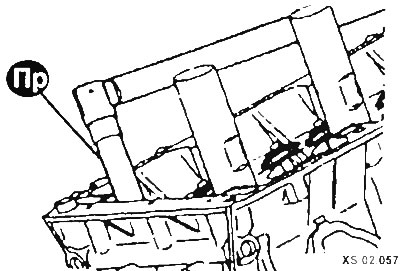

Put on hydraulic pushers (if there) staples.

ATTENTION: It is recommended to change the rocker arms complete with pushers at the same time for all cylinders.

After unscrewing the nuts, remove the valve actuator.

Remove the camshaft from the beds.

Remove the valve lifters from the cylinder head bore (if there).

Before the valves are removed, mark them and store them together with the related parts in such a way that they can be placed in their original positions during installation.

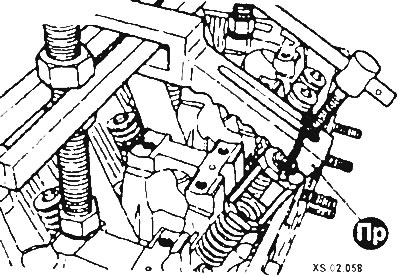

Install the valve compression tool.

Compress the springs on the first valve with a tool and remove the crackers. Carefully release the spring, remove the plate, protective sleeve and springs.

Remove the valve seal. Remove the valve from the head. If the valve is stuck in the guide (does not pass through) push it back into the head and file the keyway and valve end with a file.

Remove the spring seat.

Repeat the procedure for the remaining valves. Be sure to store all valve parts together so that they can be reassembled in their original position.

To quickly disassemble the valves, you can use the following method.

Place the old piston pin on the upper valve disc and hit it with a hammer.

WARNING: Be careful. In this case, crackers pop out, and the springs can «jump up».

Remove the valve elements as described above.

WARNING: A tool is required to install the valves.

Once the valves and all related parts have been removed and stored properly, the head should be thoroughly cleaned and inspected. If the engine is completely dismantled, complete this process completely before working on the cylinder head.