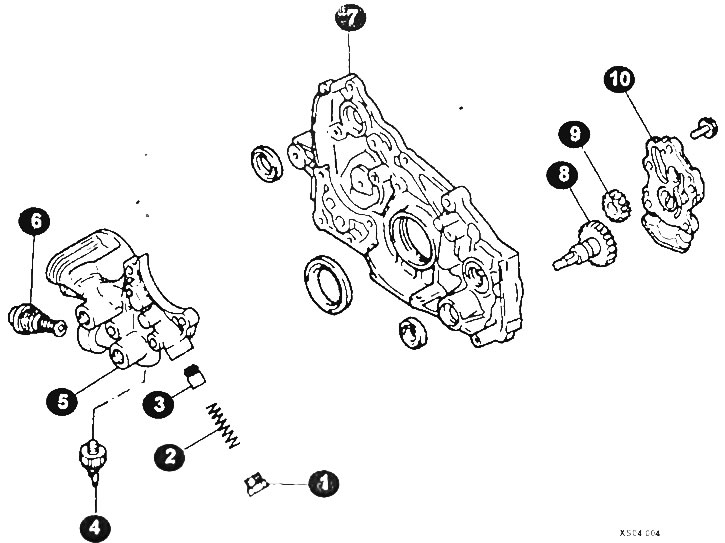

Oil pump elements

1 - cork; 2 - spring; 3 - piston of the pressure reducing valve; 4 - oil pressure sensor; 5 - oil filter bracket; 6 - oil cooler bypass valve; 7 - front cover; 8 - drive gear; 9 - driven gear; 10 - oil pump cover.

Disassembly

Remove the oil pump from the engine. To remove the pump, it is necessary to disconnect and remove the elements of the camshaft drive (lower part), as well as the oil sump.

Clean the removed oil pump from dirt, wash the external elements of the pump and covers.

Disconnect the oil receiver from the pump housing (if not already disconnected).

Having unscrewed the mounting bolts, disconnect the pump housing from the front cover of the cylinder block.

Remove pressure reducing valve (plug, spring and valve).

Clean all parts of dirt, oil and deposits.

Stubborn deposits can be removed by soaking parts in solvent.

WARNING: To avoid poisoning, avoid inhalation into the ditch and avoid contact of the solvent with exposed areas of the topic.

Checking oil pumps with internal gears

Check for foreign particles and find out the cause of their entry.

Check pump body and cover for cracks or scratches. Replace housing if defective.

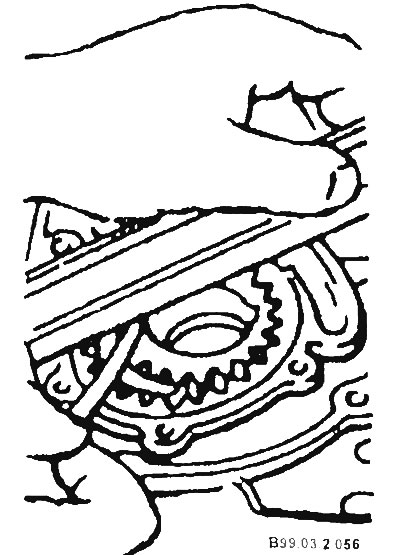

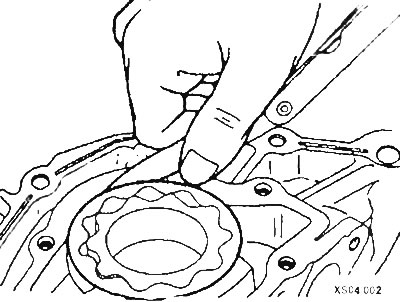

Reinstall both gears in the pump housing and check the end play between the top side of the pump housing and the top side of the gears by placing a steel straightedge and measuring it with a feeler gauge as shown in the figure. The maximum allowable clearance is 0.10 mm between the ruler and the inner gear and 0.15 mm between the ruler and the outer gear of the pump. If necessary, you can slightly reduce the axial clearance by sanding the pump housing on a straightening plate.

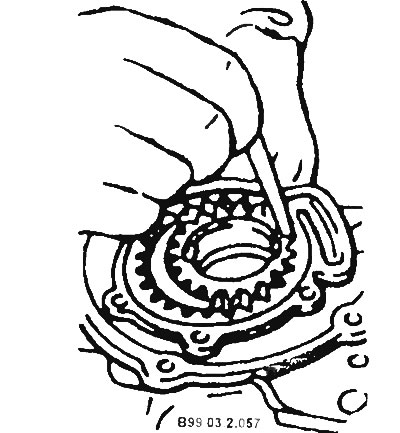

Insert a feeler gauge between the outside of the outer drive gear of the pump and the hole in the housing. The gap should not exceed 0.20 mm.

The gap between adjacent teeth should be less than 0.18 mm.

If the measured values exceed the allowable values due to wear, either the pump gears or the oil pump housing must be replaced.

Check the pressure reducing valve for scratches and signs of sticking. Dents and burrs should be removed with a fine sanding stone.

Check the pressure reducing valve spring for loss of elasticity and bending. Replace springs if defective.

Check intake pipe assembly with filter (grid) for leaks and damage to the intake screen.

Check gears for chipped material, nicks and wear.

After installing the gears and front cover, check the gears for smooth rotation.

Check the axial clearances of the gears. Required values: drive gear no more than 0.14 mm; driven gear no more than 0.12 mm.

Assembly

Lubricate all internal parts of the pump with engine oil.

Install the pump gears by aligning the marks.

CAUTION: To prevent damage to the engine, coat all oil pump cavities with grease before installing the gears to ensure oil is sucked up and fed into the engine lubrication system.

Install cover and gasket.

CAUTION: To avoid engine damage, use only original factory gaskets.

Install pressure relief valve and spring.

Tighten the pressure relief valve plug to 30 Nm using a torque wrench.

When repairing the oil pump, replace the oil filter and replace the engine oil with fresh.

ATTENTION: If the oil pressure does not immediately reach the normal level, you should shine the oil sump and check the connection of the pump to the suction pipe. If necessary, dismantle and disassemble the pump, fill the pump cavities and reassemble the pump. Running the engine without oil pressure will cause severe engine damage.