Warm up the engine in motion, the oil temperature should be at least 80°C.

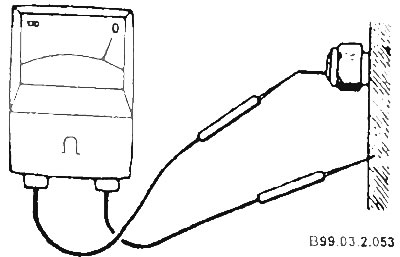

Disconnect the wire from the oil pressure sensor and unscrew it.

Insert a manometer in place of the switch.

With the engine idling, read the oil pressure on the gauge.

After applying sealant to 2-3 threads, insert and secure the oil pressure sensor.

The oil pressure sensor is mounted in front of the engine. When the engine is running and the oil pressure is above about 0.7 bar, the sensor is activated and switches off the warning light circuit, which does not light up. At an oil pressure below 0.7 bar, the sensor returns to its original position and connects the electrical circuit of the warning lamp. The lamp lights up.

You can check the sensor readings in the set mode in the following order:

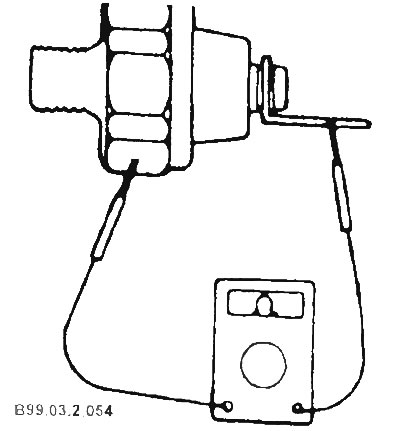

- Stop the engine and remove the wire from the oil pressure sensor.

- Connect an ohmmeter between the oil pressure sensor terminal and the engine block. The resistance should be 0 ohm.

- When the engine is idling, the instrument should show infinity.

- If one of the two measurements does not correspond to the required value, the oil pressure sensor must be replaced. If both measurements are correct, check the electrical wire going to the test light.

Connect the wire to the oil pressure sensor.

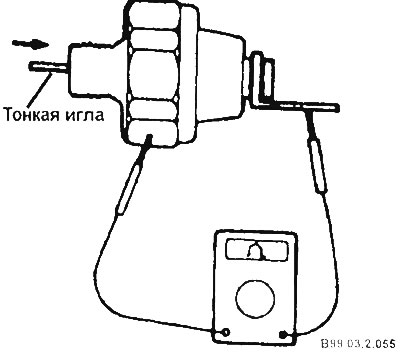

Checking the removed oil pressure sensor is as follows:

Connect an ohmmeter between the terminal and the oil pressure sensor housing. The resistance should be 0 ohm.

Insert a thin needle into the oil hole of the switch and press lightly. The device should show infinity.

If at least one of the two measurements fails, the sensor must be replaced.

Use an air pump to create a pressure of 0.5 bar in the oil hole of the sensor. The resistance should be 0 ohm. With this procedure, you need to take care of the release of air.