Removing spark plugs (arrows), check their condition.

It is recommended to remove the spark plugs every 6 thousand km for a visual assessment of the mechanical condition of the engine.

Light brown or gray or rusty red residue when using unleaded fuel) on a candle that has worked for any period of time is considered normal. Any other color or abnormal amount of sediment indicates that there is a problem with the engine. The gap between the center and side electrodes can increase by no more than 0.025 mm every 1500 km under normal conditions.

If a spark plug is installed in an engine that is running properly, then the spark plugs can be removed, cleaned, adjusted (gap) and installed back without any damage to the engine.

If the spark plug is fouled and malfunctioning, the cause should be investigated and the spark plug cleaned or replaced.

There are several reasons why a spark plug can become fouled, and you can learn to identify these by visually inspecting the spark plug.

Spark plugs suitable for use in an engine vary in a large number of glow numbers. The amount of heat that the candle absorbs is determined by the length of the lower insulator. The longer the insulator, the hotter the candle will be at work; the shorter the insulator, the colder. Spark plugs that absorb (or save; little heat and remain too cold will pick up lead, oil and carbon residues as they are not hot enough to burn these residues. This leads to pollution and, consequently, interruptions in work. Candles that absorb too much heat don't have precipitation. But the electrodes burn out quickly and, in some cases, the result can be premature (incandescent) ignition. This ignition occurs when the tip of the spark plug becomes so hot that it ignites the fuel mixture before true spark ignition occurs. This pre-ignition is usually the cause of knocking at low speed and high load. In severe conditions, the temperature may become sufficient to ignite the mixture in the combustion chamber before it is at the end of the spark plug. In this case, great damage will be done to pistons, rings and valves.

In most cases, the heat ratings recommended by the manufacturer are correct and provide good performance over a wide range of operating conditions. However, if you mainly drive long distances at high speed, then you can set the candles to one unit «colder» standard. If you mainly drive short distances where the engine cannot always reach operating temperature, more «hot» candles can help burn off the precipitation that usually accumulates in such conditions.

Removing

When removing spark plug wires, always hold them by the rubber cap.

Do not confuse wire numbers when removing and installing.

Remove the wires from the spark plugs by holding the cap on the wire. If the cap sits tightly on the candle, then to remove it, you need to shake it while pulling it out. Do not pull the wire by the insulation.

Loosen all the spark plugs with a wrench by turning them about two turns.

NOTE: The cylinder head is made of aluminium. If possible, remove spark plugs when the engine is cold to avoid damaging the threads.

If the spark plugs are difficult to remove, use motor oil or silicone spray around the spark plug seat and wait a few minutes.

If compressed air is available, use it to clear the area around the spark plugs. On the other hand, you can use a rag or brush for this. Make sure that foreign objects do not get into the spark plug hole.

Remove the spark plugs by twisting them by hand.

Examination

Check spark plugs for deposits and wear.

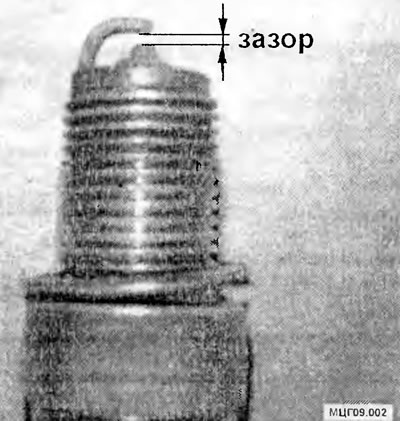

If they will not be replaced, clean them thoroughly. Remember that any sediment on the candles reduces the effectiveness of their work. Spark plugs can be cleaned in a special spark cleaner, which is sometimes found at service stations, or they can be cleaned with a stiff brush. After cleaning, the electrodes should be processed with a flat file. You can not use emery skin, because. it can leave small particles on the electrodes. The electrodes should be flattened, they should become flat and have sharp corners. The rounding of the electrodes reduces the voltage on them by more than 50%. Check the gap between the spark plug electrodes before installing. Electrode «masses» must be parallel to the center electrode, and a special probe (1) must pass through the gap with slight pinching

WARNING: Never adjust gap on spark plugs with platinum coated electrodes.

Always check the gap on new spark plugs too. To measure the gap, it is not recommended to use a flat feeler gauge, since you can make mistakes when measuring.

A wire probe usually has an electrode bender attached to it. Use it to set the correct gap. Never bend the center electrode. Be careful not to bend the side electrode too much or too often. It can break off in the engine and cause damage to it.

In the absence of a wire probe of the required thickness, you can use a hacksaw blade for cutting metal, which is usually 0.8 mm thick.

Installation

Lubricate the spark plug threads with engine oil. Insert the spark plugs into the holes and tighten by hand. Make sure that they fit exactly on the thread.

Tighten the spark plugs. Do not overtighten them, just until tight. If there is a torque wrench, tighten with a torque of 15-20 Nm.

Put wire caps on the spark plugs. Check the tightness of the caps.