On 16-valve engines, the electronic control unit determines the ignition timing from sensors and generates a spark using two ignition coils.

For electronic ignition systems, the ignition voltage is up to 30 kV; under adverse conditions, voltage peaks can break through the insulation.

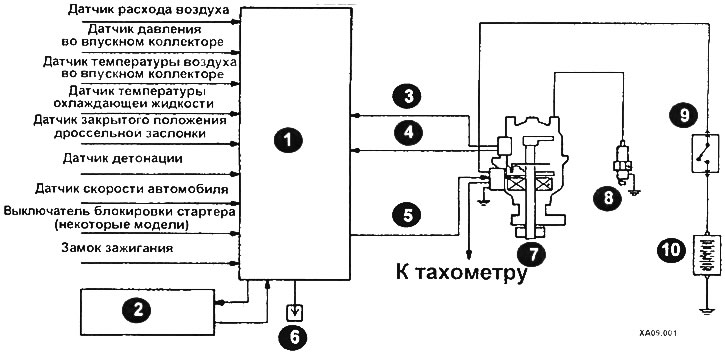

Models with ignition distributor

Scheme of the ignition system of models with an ignition distributor

1 - control unit; 2 - automatic transmission control unit; 3 - crankshaft position sensor; 4 - TDC sensor of the first cylinder; 3 - ignition coil; 6 - for adjusting the ignition timing; 7 - ignition distributor; 8 - spark plugs; 9 - ignition lock; 10 - battery.

The electronic engine control unit creates and breaks the primary circuit of the ignition coil, thereby adjusting the ignition timing.

The electronic engine control unit, using the crankshaft position sensor built into the ignition distributor, determines the angular position of the crankshaft and provides the optimal ignition timing depending on the engine operating mode.

When operating a car (at high altitude) or driving with a cold engine, the ignition timing advances slightly to ensure optimum engine performance.

When knocking occurs, the ignition timing is gradually reduced until knocking stops.

When the automatic transmission shifts gears, the ignition timing is reduced, eliminating the car's jolt when shifting gears.

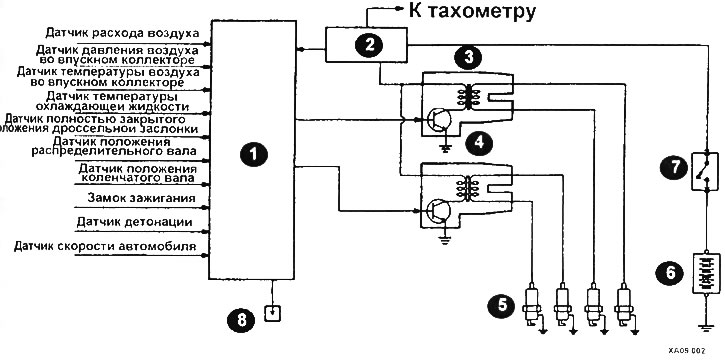

Models without ignition distributor

Scheme of the ignition system of models without an ignition distributor

1 - engine control unit; 2 - ignition system malfunction sensor; 3 - ignition coil A; 4 - ignition coil B; 5 - spark plugs; 6 - battery; 7 - ignition lock; 8 - for adjusting the ignition advance angle.

This ignition system has two ignition coils (A and B) with built-in power transistors that supply high voltage to the spark plugs of cylinders 1, 4 and 2, 3, respectively.

Interruption of the primary circuit of the ignition coil A creates a high voltage in the secondary winding of coil A. The high voltage thus created is applied to the spark plugs of cylinders No. 1 and 4.

At this point, sparking occurs simultaneously on the electrodes of both spark plugs. In this case, the piston of one of the cylinders is on the compression stroke, and the piston of the other cylinder is on the exhaust stroke. The ignition of the compressed air-fuel mixture occurs only in the cylinder whose piston is at the end of the compression stroke.

Similarly, when the primary circuit of ignition coil B is interrupted, high voltage is applied to the electrodes of the spark plugs for cylinders 2 and 3.

The electronic engine control unit sequentially turns on and off the silt transistors built into the ignition coils.

The electronic engine control unit, receiving signals from the camshaft position sensor and the crankshaft position sensor, determines which of the power transistors of the ignition coils to apply a control pulse to. The electronic unit, receiving a signal from the crankshaft position sensor, determines the angular position of the latter, determines the optimal ignition timing for a given engine operation mode.

The main malfunctions of the ignition system are caused by loose or oxidized contacts, or a high voltage ground fault. Before drawing a conclusion about the malfunction of any element in the ignition system, check the condition of the wires or electrical circuits of the ignition system.