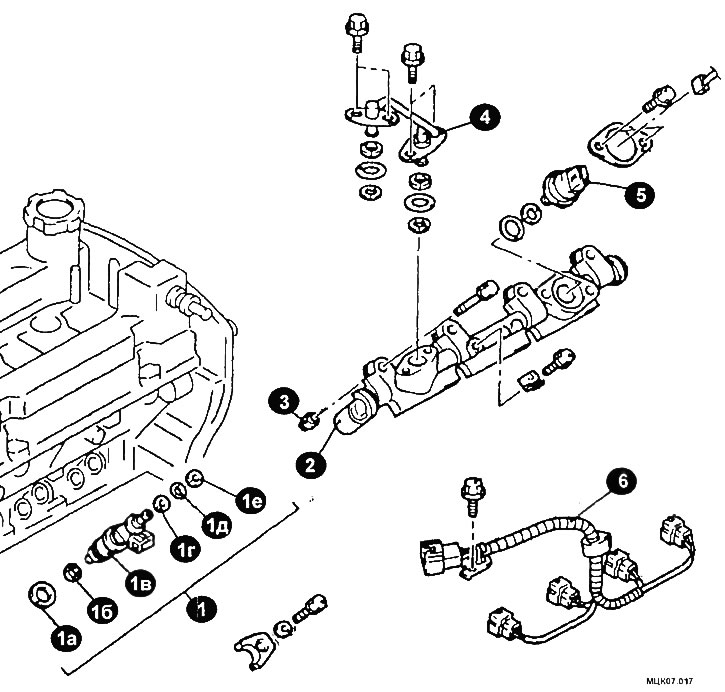

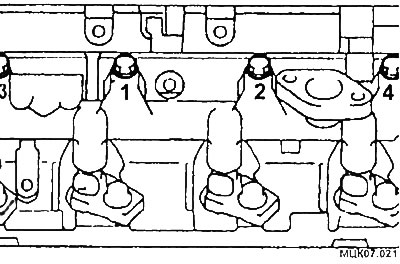

Injector fittings

1 - nozzle; 1a - gasket; 1b - profile washer; 1c - nozzle; 1g - ring; 1d - ring seal; 1e - ring; 2 - fuel manifold; 3 - insulator; 4 - fuel tube; 3 - fuel pressure sensor; 6 - wiring harness.

Removing

Remove the ground wire from the battery.

Remove the engine cover.

Relieve fuel pressure.

Disconnect the fuel pressure sensor connector.

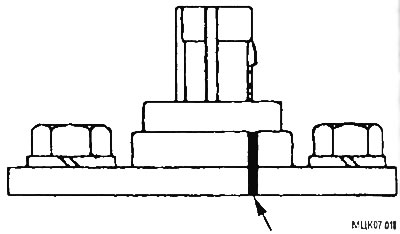

When reusing the fuel pressure sensor, make a match mark on the flange and on the sensor (arrow).

If a new fuel pressure sensor is installed, it must be replaced together with the flange - as a kit.

Remove the fuel pressure sensor and gasket and ring.

Remove the air filter, throttle body and intake manifold.

Turn away bolts, disconnect sockets and remove a plait of wires of atomizers.

Remove the support bracket for the injector wiring harness.

Remove the fuel pipe.

Remove the bottom ring, O-ring and top ring.

After unscrewing the bolt, remove the washer and nozzle holder.

Having unscrewed the bolts, remove the fuel manifold with injectors as an assembly without separating them.

Unscrew the bolt, remove the insulator

Remove the injector nozzle gaskets, profile washers, lower O-ring and upper O-ring.

Installation

Installation is carried out in the reverse order, taking into account the following.

Install rings and O-ring.

Make sure the lower ring is installed correctly (the outer diameter of them of his ring is 14.8 mm). Do not confuse it with the fuel pressure sensor support ring.

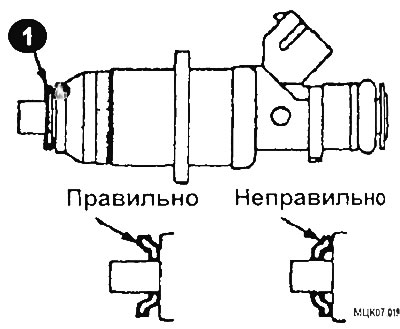

Apply grease to the surface of the profile washer (1) to prevent it from falling when installing the nozzle, install it on the nozzle.

The profile washer is not reusable. Carefully, trying not to damage the seal, and turning the nozzle to the right and left, connect it to the fuel manifold.

If the nozzle rotates in its seat with «jamming», then it is possible «bitten» ring seal.

Remove the injector, check the condition of the O-ring, reconnect the injector to the fuel manifold and recheck the build quality.

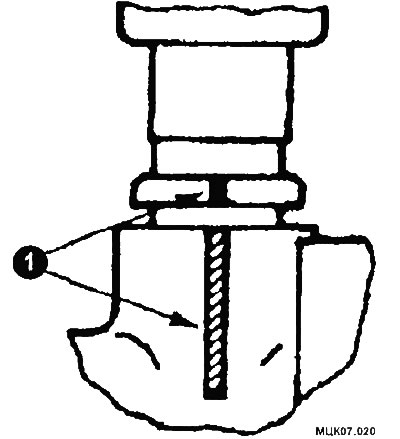

Align match marks (1) injectors and fuel manifold.

Install the injector gasket and insulator into the block head.

Install the injector and fuel manifold assembly into the block head and secure it with hand force.

Install nozzle holder and washer and tighten to specified torque.

Tighten the fuel rail and injector assembly mounting bolts.

Install rings and O-ring.

Make sure the top ring is installed correctly: (outer diameter is 14.8 mm). Do not confuse it with the fuel pressure sensor support ring.

Coat the O-ring with clean engine oil.

Install the fuel pipes at a right angle into the channels of the high pressure fuel pump.

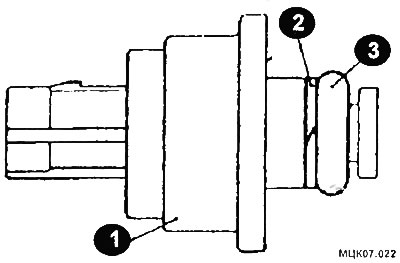

Set the ring (2) and O-ring (3) to the fuel pressure sensor (1). The outer diameter of this O-ring is 15.1 mm.

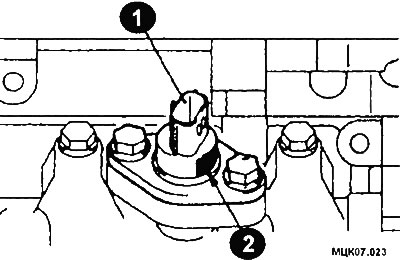

Coat the fuel pressure sensor gasket with engine oil. Install the fuel pressure sensor (1) so that his number plate (2) positioned as shown in the figure to the right.

If the fuel pressure sensor is reused, then before removing it, it is necessary to mark the relative position of its body and flange.

Check the tightness of the fuel system, remove air from the high pressure fuel line.