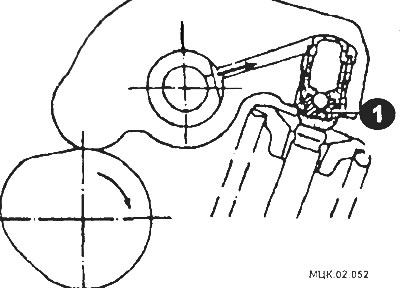

If any of the above situations occurs, extraneous noise can be eliminated by removing air from the hydraulic pushers.

Check the condition of the engine oil and top up or change it if necessary.

If the oil level is insufficient, air will be sucked in through the oil pick-up with a grid and will enter the oil channel.

If the oil level is higher than required, the oil will mix with the air in the crankshaft and there will be a lot of air in the oil.

If the oil is old, the air will not quickly separate from the oil, and the proportion of air in the oil will be increased.

If air with oil enters the over-plunger cavity of the hydraulic pushers, the air inside the over-plunger cavity will be compressed when the valve is opened, and the hydraulic pusher will not be compressed, which will lead to extraneous noise when the valve is closed.

If air is removed from the oil, the operation of the hydraulic lifters will return to normal.

Let the engine idle for 1-3 minutes to warm it up.

Within 15 seconds, increase the engine speed to 3000 rpm, then sharply reduce the speed to idle and let the engine idle for 15 seconds, then repeat the cycle and check if the extraneous noise disappears during normal operation, the sound disappears after 10- 30 repetitions, but if after 30 repetitions or more the sound level has not changed, the probable cause of the extraneous sound is not the appearance of air inside the hydraulic pushers.

After the disappearance of extraneous sound, repeat the cycle 5 more times.

Let the engine idle for 1-3 minutes and check that the sound has disappeared.