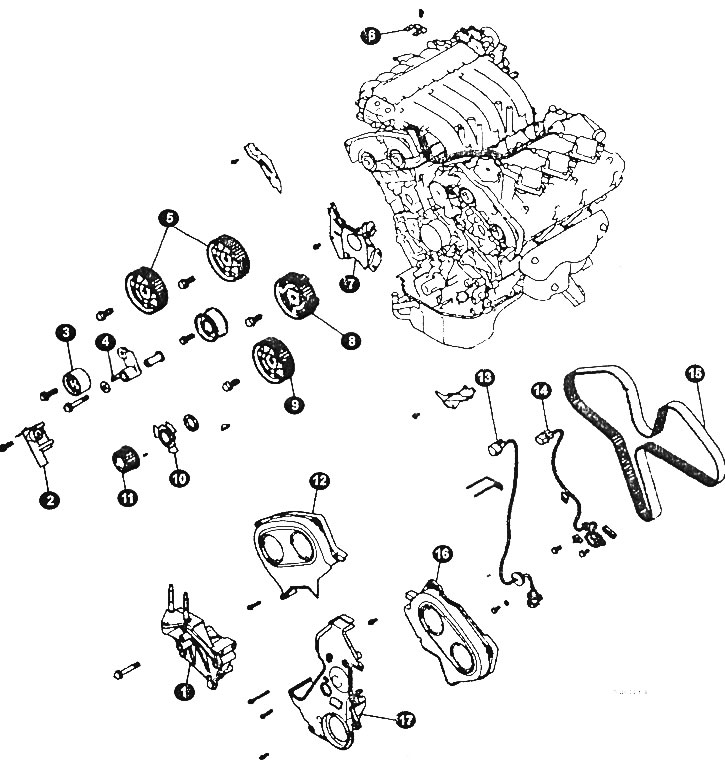

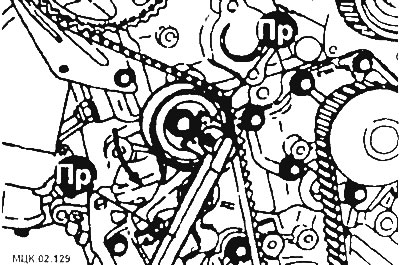

Adjusting elements of a gear belt of the engine 6А12 (DOHC)

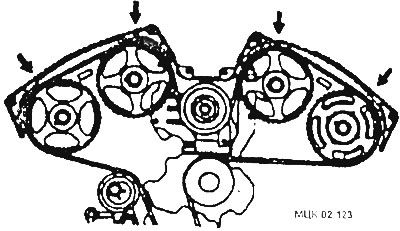

1 - engine support; 2 - tensioner regulator; 3 - tension roller, 4 - roller bracket; 3, 9 - gear, camshaft wheels; 6 - bracket for fastening the crankshaft speed sensor; 7 - rear middle cover; 8 - camshaft gear (with toothed plate); 10 _ toothed plate; 11 - gear wheel crankshaft; 12 - top right' cover; 13, 14 - crankshaft sensors; 15 - toothed belt; 16 - upper left cover; 17 - middle cover.

Removing

Before removing the timing belt of the camshaft drive, it is necessary to remove the elements shown in the figures above (alternator belt, crankshaft sensor covers, engine brackets).

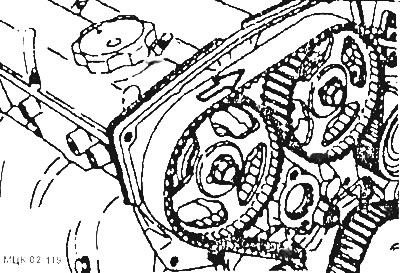

Set the number one piston to TDC on the compression stroke. Align the alignment marks.

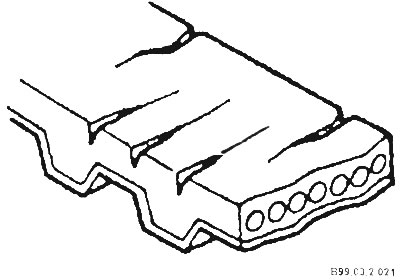

Put an arrow in the direction of rotation of the toothed belt on the belt.

After releasing the mounting bolt, turn the tension roller (loosen the belt tension).

After unscrewing the mounting bolts, remove the tensioner (complete).

Remove the camshaft drive belt.

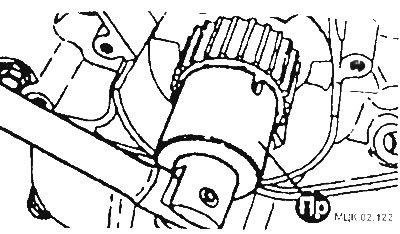

If necessary, remove the camshaft gears using the tool.

Examination

Visually check the condition of the toothed belt. If any of the following defects are found, replace the belt.

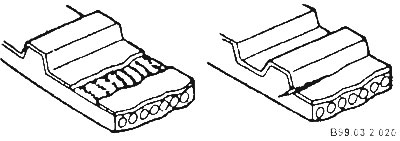

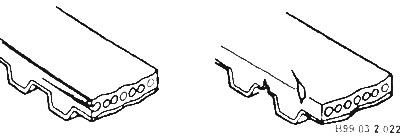

Teeth are broken or cracked at the base

Probable causes of defects; jamming of the camshaft or distributor; damaged crankshaft and or camshaft seals.

The reverse side of the belt is badly worn or cracked

Probable causes of defects are jamming of the tension roller, engine overheating; belt hits the cover.

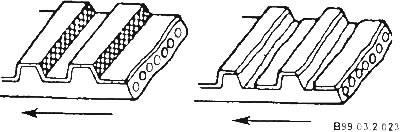

The side of the belt is worn. The edges of the belt are rounded, the cord threads are disheveled and come out

Probable causes of defects: incorrect installation of the belt; the side surfaces of the idler roller are notched or heavily worn.

Tooth wear. The outer coating on the thrust surface of the teeth is worn off, the rubber layer under it is worn and has a whitish color

Possible causes of defects: poor sealing of the belt cover; leak in the water pump; incorrect operation of the camshaft; incorrect operation of the distributor; excessive belt tension.

Oil, coolant or water on the belt

Possible causes of defects: poor sealing in glands; leak in the water pump; poor belt cover seal.

Installation

Install the camshaft gears.

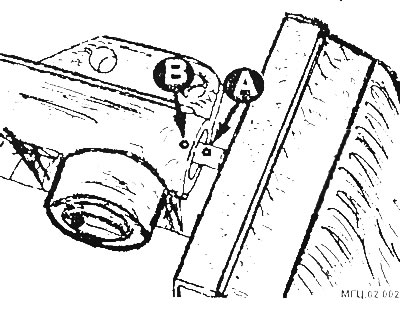

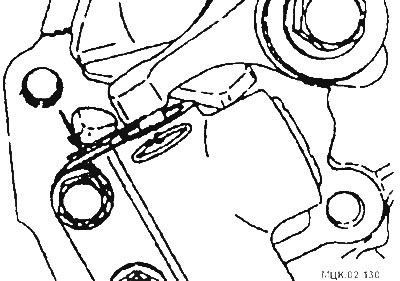

Clamp the tensioner adjuster in a soft-jawed vise (without tilt). holes (A) And (IN) should be on top.

While moving the jaws of the vise, align the holes of the tensioner and insert the wire with a diameter of 1.4 mm.

Remove tensioner adjuster from vise and install on engine.

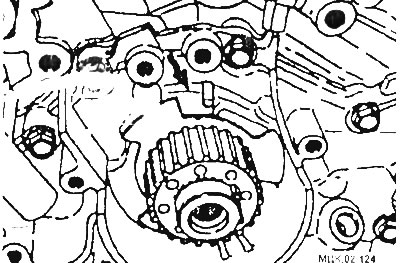

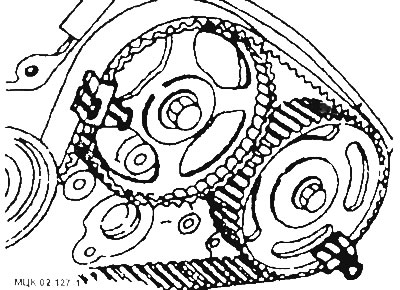

Turn the crankshaft gear so that the timing mark of the gear does not reach the mark of the crankcase (three teeth).

Align the timing marks on the camshaft gears.

Align the timing marks on the crankshaft gear.

Establish a gear belt of a drive of camshafts. Work very carefully as the camshafts can turn freely.

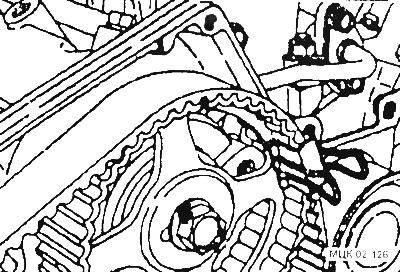

Start installing the belt from the crankshaft, then pass the belt through the tension roller (released) on the gear wheels of the left camshafts.

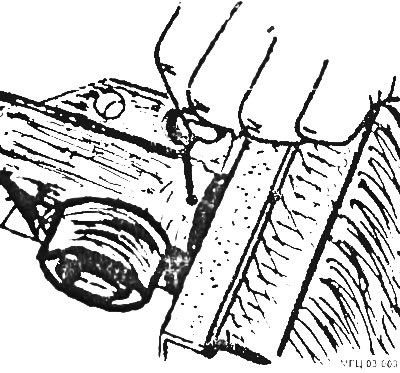

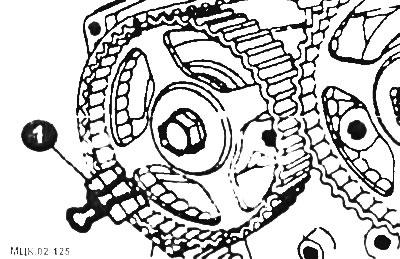

ATTENTION: For ease of use, use paper clips (1).

Do not knock down the position of the installation marks.

Put on a belt on cogwheels of the right camshafts.

Pass the belt through the water pump gear.

ATTENTION: If an old belt is installed, the direction of rotation must not be changed.

After loosening the tensioner bolt, move the tensioner towards the toothed belt. Then tighten the bolt to 50 Nm.

Check that the timing marks on the belt match.

Turn the engine crankshaft counterclockwise 1/4 turn.

Turn the engine crankshaft clockwise until the belt alignment marks match.

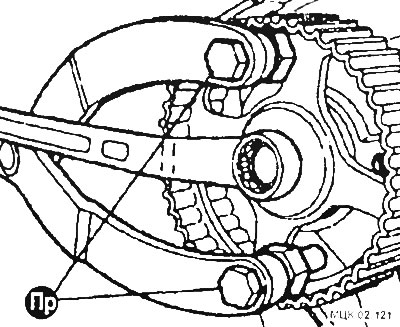

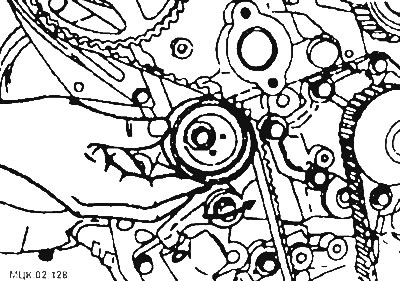

After loosening the special tensioner roller bolt, install the tool in the hole.

Turn the tension roller counterclockwise to a torque of 3 Nm.

Tighten the central bolt to 48 Nm.

Turn the engine crankshaft two full revolutions and pause for 5 minutes

Remove the wire from the tensioner and release the pusher.

If the wire is difficult to remove and if the protrusion of the pusher does not correspond to the required value, repeat the above operations.