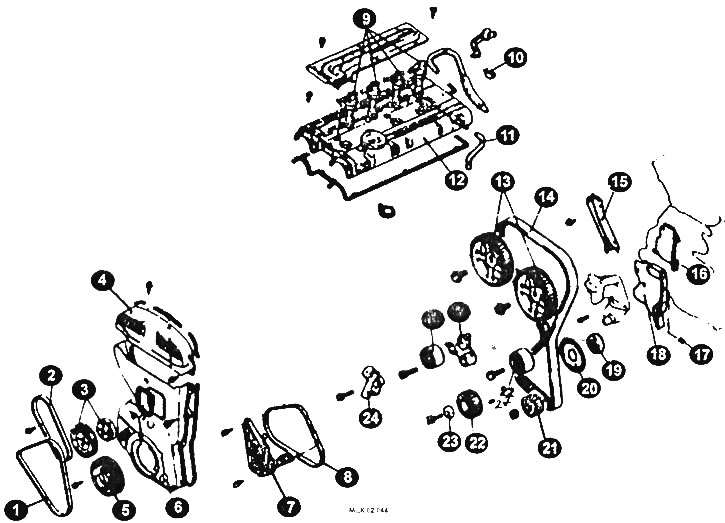

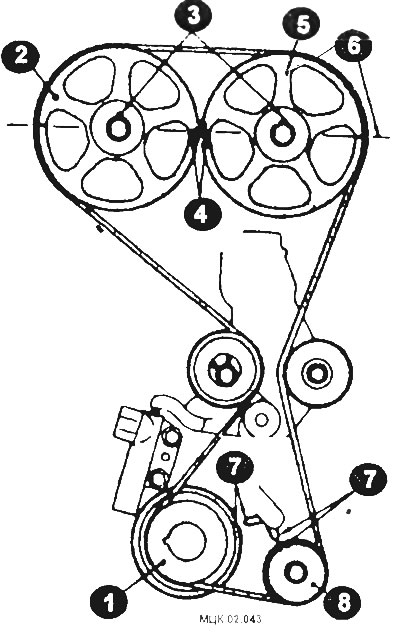

Adjusting elements of a gear belt

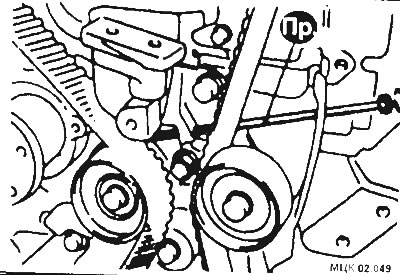

1 - wedge and alternator belt; 2 - power steering pump belt; 3 - gear wheel of the water pump; 4 - top cover of the toothed belt; 3 - crankshaft pulley; 6 - bottom cover of the toothed belt; 7 - tensioner brackets; 8 - air conditioning compressor belt; 9 - tip of spark plugs; 10 - semicircular plug; 11 - crankcase ventilation hose; 12 - cylinder head cover; 13 - camshaft gears; 14 - toothed belt; 15, 16, 18 - rear cover of the toothed belt; 17 - hatch plug: 19 - bypass roller; 20 - flange; 21 - crankshaft gear; 22 - gear wheel of the oil pump; 23 - sleeve; 24 - automatic tensioner.

Removing

Disconnect the ground wire from the battery.

Remove the left engine mudguard.

With the jack and wide board under the oil sump, raise the jack enough to support the engine without lifting it up.

Remove the engine support bracket.

Remove the alternator belt and power steering belt.

After removing the tensioner, remove the belt.

Remove the water pump pulley together with the power steering pump pulley.

Remove the crankshaft pulley.

Remove the upper and lower camshaft timing belt covers.

Remove the upper center cover, crankcase ventilation hose and breather hose from the cylinder block cover.

Tag and disconnect the spark plug wires from the spark plugs.

Remove the cylinder block cover and its gasket.

Remove the round plug from the cylinder head.

Turn the crankshaft clockwise until all alignment marks are aligned. In this case, the piston of the first cylinder of the engine will be at TDC of the compression stroke.

WARNING: Do not move the camshafts or crankshaft in this position, as this can cause very serious damage.

Remove the automatic toothed belt tensioner.

Remove the toothed belt.

Remove the tensioner pulley.

Carefully inspect the toothed belt for cracks or wear. The belt must be in excellent condition. At the slightest defect, the belt should be replaced. It is recommended to replace the belt every time it is removed from the engine, especially on high mileage engines.

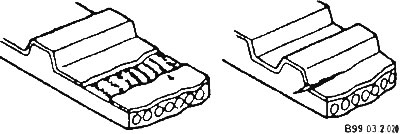

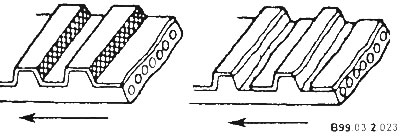

Visually check the condition of the toothed belt. If any of the following defects are found, replace the belt.

Teeth are broken or cracked at the base

Possible causes of defects:

- jamming of the camshaft and distributor;

- crankshaft and/or camshaft oil seals are damaged.

The reverse side of the belt is badly worn or cracked

Possible causes of defects:

- jamming of the tension roller;

- engine overheating;

- belt hits the cover.

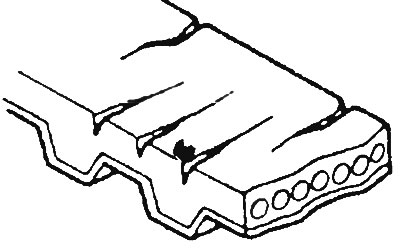

The side of the belt is worn. The edges of the belt are rounded, the cord threads are disheveled and come out

Possible causes of defects:

- incorrect installation of the belt;

- the side surfaces of the idler roller are notched or heavily worn.

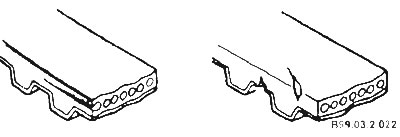

Tooth wear. The outer coating on the thrust surface of the teeth is worn off, the rubber layer under it is worn and has a whitish color

Possible causes of defects:

- poor sealing of the belt cover;

- leak in the coolant pump;

- incorrect operation of the camshaft;

- incorrect operation of the distributor;

- excessive belt tension.

Oil, coolant or water on the belt

Possible causes of defects:

- poor sealing in the glands;

- leak in the coolant pump;

- poor belt cover seal.

Check the degree of wear of the gears and tensioner rollers. The teeth of the wheels must have a clear profile, must not be rounded, and the cavities between the teeth must be clean. The tensioner roller and bypass roller should rotate freely without binding or unusual noise.

Replace the tensioner if it shows any signs of oil leakage.

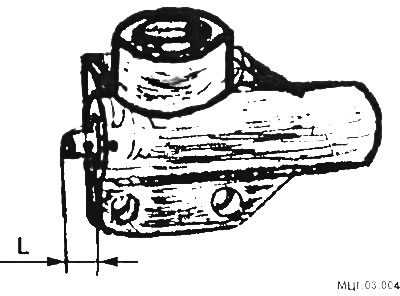

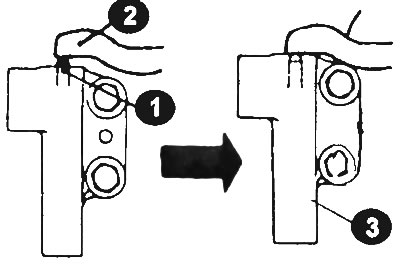

Check the automatic tensioner for wear, damage. Carefully inspect the tip of the push rod for signs of wear. Measure the protrusion length of the push rod. Required value 12 mm (size L). If this parameter does not match, replace the automatic tensioner.

Install the automatic tensioner in a vise with protective jaws. The assembly must be in a horizontal position. While tightening the vise, compress the tension tip. If the rod retracts freely, the assembly has lost tension properties and must be replaced. When the rod is retracted, a lot of resistance should be felt.

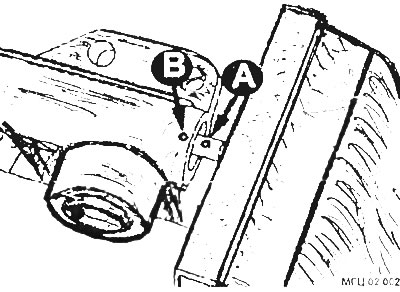

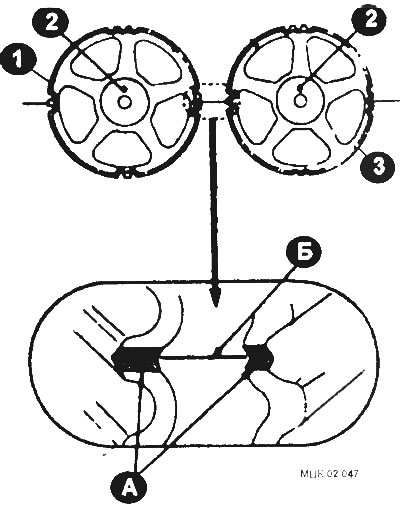

After retracting the stem into the auto-tensioner housing, align the hole in the push rod (A) with a hole in the body (IN). After aligning the holes, cotter the push rod in place with a piece of hard wire 1.5 mm in diameter. The tensioner is easier to install with the push rod retracted. Leave the wire in place and remove the knot from the vise.

Correct position of the toothed belt

1 - gear; 2 - gear track of the exhaust camshaft; 3 - key; 4 - installation marks; 5 - gear wheel of the intake camshaft; 6 - installation marks; 7 - installation marks; 8 - crankshaft gear.

Installation

Installing the toothed belt is carried out in reverse order, taking into account the following:

Install the tensioner housing to the engine.

Establish a gear belt of a drive of camshafts. You need to start with the crankshaft, then through the gear wheel of the oil pump to the gear wheels of the camshafts (through the bypass roller and tensioner).

CAUTION: Do not knock off the position of the alignment marks. If an old belt is installed, the direction of rotation should not change.

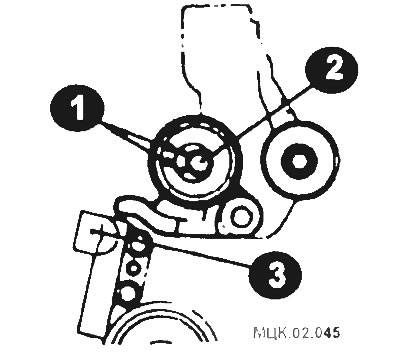

The location of the alignment marks of the gears of the camshafts

1 - gear exhaust valves; 2 - gear locating pin; 3 - gear wheel of inlet valves; A - camshaft gear marks; B - a label located on the cylinder head.

Loosen tensioner bolt (3), move the tension roller until the belt is evenly tensioned and the bolt is tightened. Holes in the roller (1) must be placed to the left of the central bolt (2).

Check that the timing marks on the belt match.

Rotate the crankshaft 1/4 turn counterclockwise.

Rotate the crankshaft until the alignment marks on the toothed belt match.

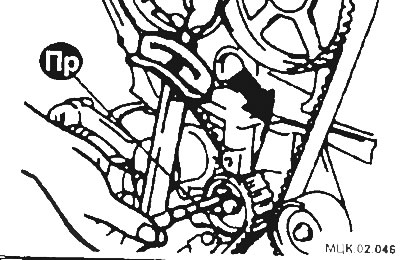

After loosening the tensioner bolt, install the special tool in the roller hole.

Turn the tension roller with a torque of 3 Nm.

Tighten the central bolt to 50 Nm.

Turn the engine crankshaft two full revolutions and pause for 5 minutes.

Remove the wire from the tensioner and release the pusher.

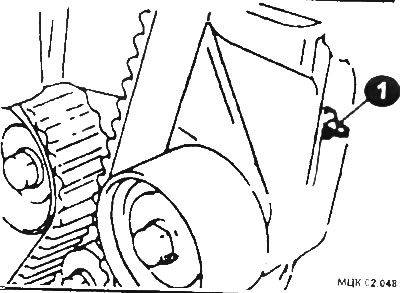

Check pusher protrusion. The required value is 3.5-4.5 mm. Otherwise, do the following.

Screw the special threaded tool into the engine hole.

Adjust the required amount of protrusion of the pusher (1) (gap between tensioner (3) and tension lever (2)).

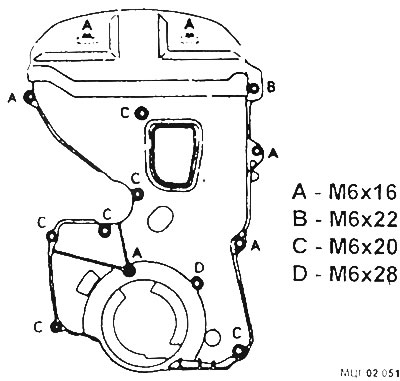

After checking the coincidence of the alignment marks of the toothed belt, install the front engine covers. Remember that the cap screws vary in length.

Arrangement of bolts of fastening of forward covers of the engine

Further installation of the removed elements is carried out in the reverse order.