MPI Models

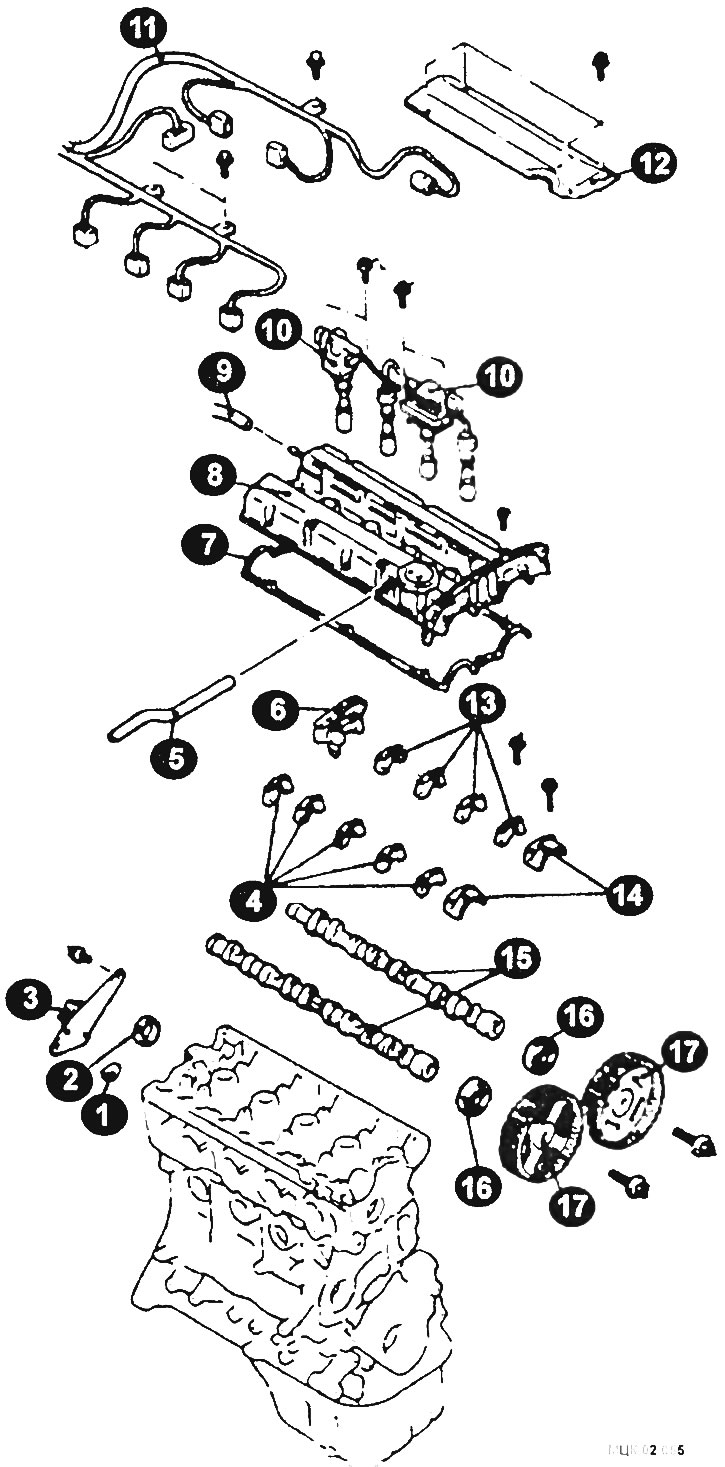

Camshaft fittings. MPI Models

1 - semicircular insert; 2 - stuffing box; 3 - ignition system sensor; 4, 13 - camshaft bearing caps; 5 - branch pipe of the forced ventilation system; 6 - rear cover of the camshaft bearings; 7 - gasket; 8 - cylinder head cover; 9 - connection of the crankcase ventilation hose; 10 - ignition coil; 11 - harness of the engine control system; 12 - top cover of the engine; 14 - front cover of the toothed belt; 15 - distributive fell; 16 - camshaft seal; 17 - camshaft gear.

Removing

Disconnect the ground wire from the battery.

Remove the camshaft drive belt.

Remove the top cover.

Having unscrewed the bolts, remove the ignition coil assembly with candle tips.

Remove the crankcase ventilation hose and the forced ventilation system pipe from the cylinder head cover! crankcase.

Disconnect the electrical connectors and remove the engine management wiring harness.

Remove the ignition malfunction sensor assembly.

Remove the cylinder head cover along with the gasket.

Remove the semi-circular insert.

Holding the camshafts with a wrench, unscrew the bolts securing the camshaft gears and remove the wheels.

Remove the camshaft seals.

Remove the O-ring.

After unscrewing the bolts, remove the front camshaft bearing caps.

Turn away bolts, remove a back cover of the bearing of a camshaft.

Turn away bolts of fastening of covers of camshafts on several receptions, remove covers and camshafts.

Installation

Installation is carried out in the reverse order, taking into account the following:

Coat the bearing journals and camshaft lobes with engine oil.

Lay the camshaft in the bed of the cylinder head.

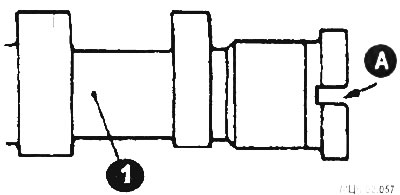

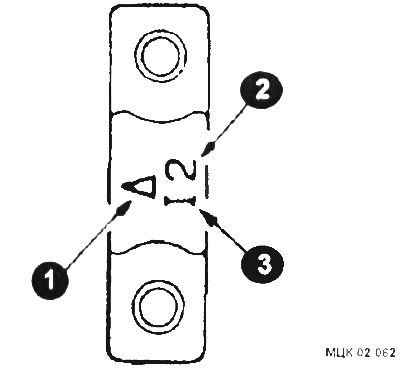

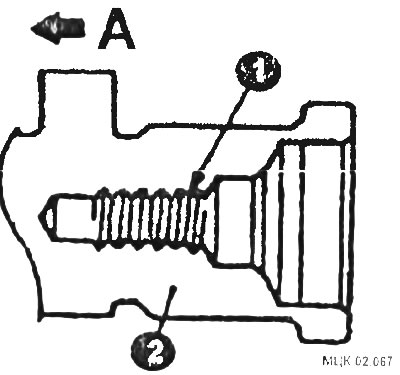

Do not mix up the camshafts. Exhaust camshaft (1) has a slot (A) on its backside.

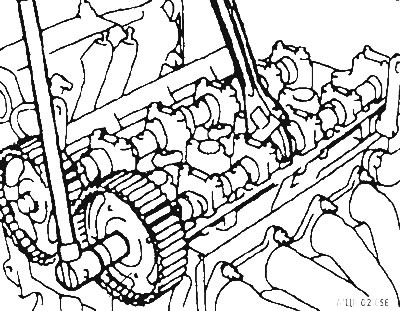

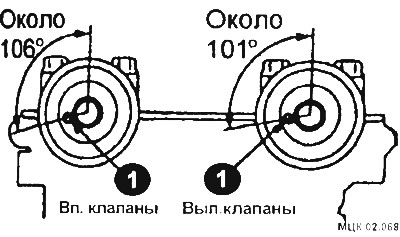

Position the dowel pins (1) camshafts as shown.

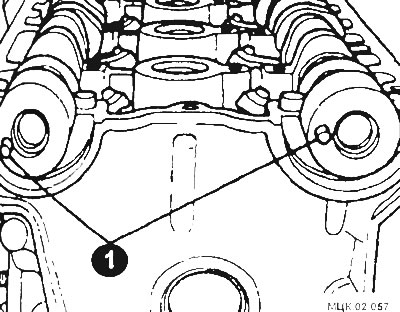

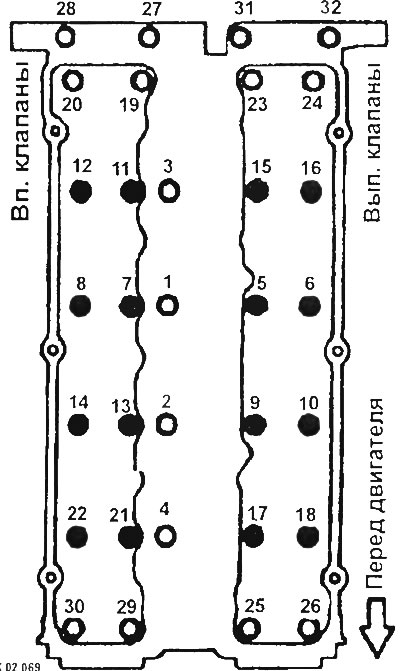

Position the camshaft bearing caps correctly.

Check the camshaft identification marks and 2 bearing cap numbers, install them, taking into account their correspondence and the orientation of the mark «before» (1). The intake camshaft has an identification symbol I (3). The exhaust camshaft has the identification symbol E.

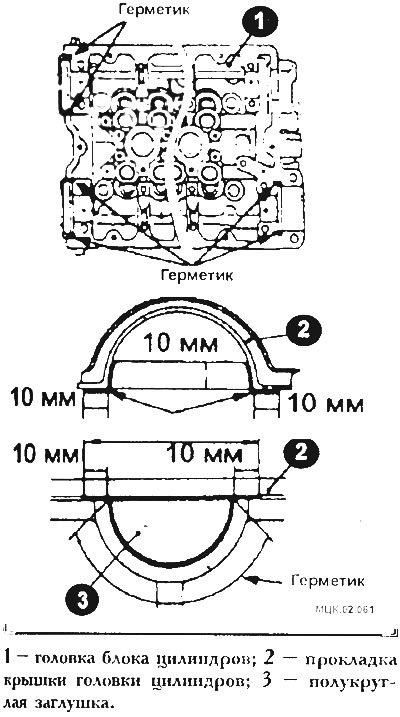

Apply sealant to the marked areas of the cylinder head.

Tighten the camshaft bearing caps in two or three steps. Then tighten the bolts to the final required torque.

- Front and rear covers 25 Nm.

- Other caps 12 Nm.

Make sure the rocker arms are correctly oriented with respect to the valve stems and tappets.

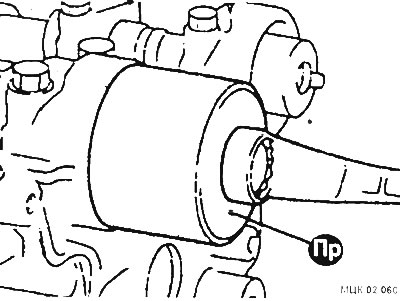

special fixture (1) or a mandrel made from a pipe, install the gland.

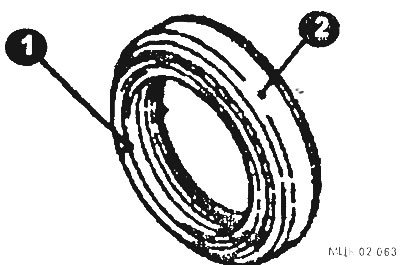

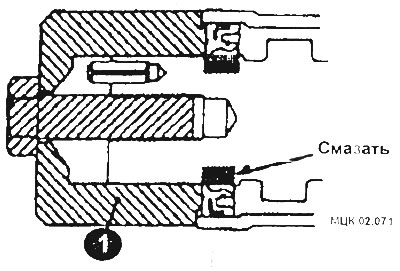

Lubricate the edge with engine oil (1) stuffing box (2) camshaft.

When pressing the camshaft oil seal, use a special tool.

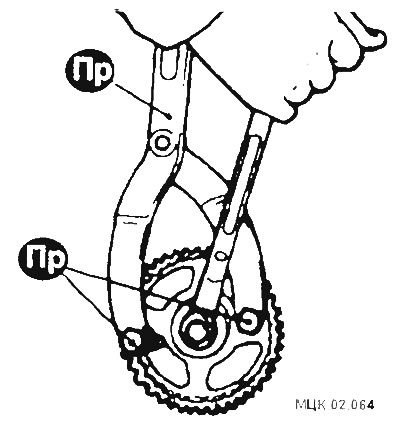

To stop the pulley from turning, use a special tool, and then tighten the bolts to a torque of 90 Nm.

GDI Models

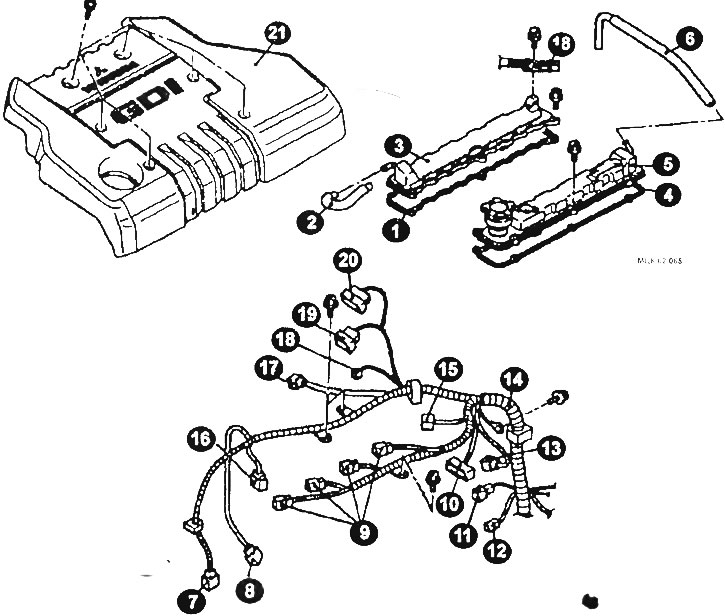

External elements of the engine. GDI Models

1, 4 - cylinder head cover gasket; 2 - hose of the engine ventilation system; 3 - cylinder head cover (intake valves); 5 - cylinder head cover (exhaust valves); 6 - hose of the engine ventilation system; 7 - connector of the crankshaft position sensor; 8 - oxygen sensor connector; 9 - ignition coil connector; 10 - ignition system sensor connector; 11 - coolant temperature sensor connector; 12 - connector for the sensor of the coolant temperature indicator; 13 - camshaft position sensor connector; 14 - wiring harness; 13 - wiring harness connector; 16 - fuel pressure sensor connector; 17 - connector harness of the engine control system; 18 - connector of the exhaust gas recirculation system; 19 - throttle position sensor connector; 20 - throttle servo connector; 21 - the upper casing of the engine.

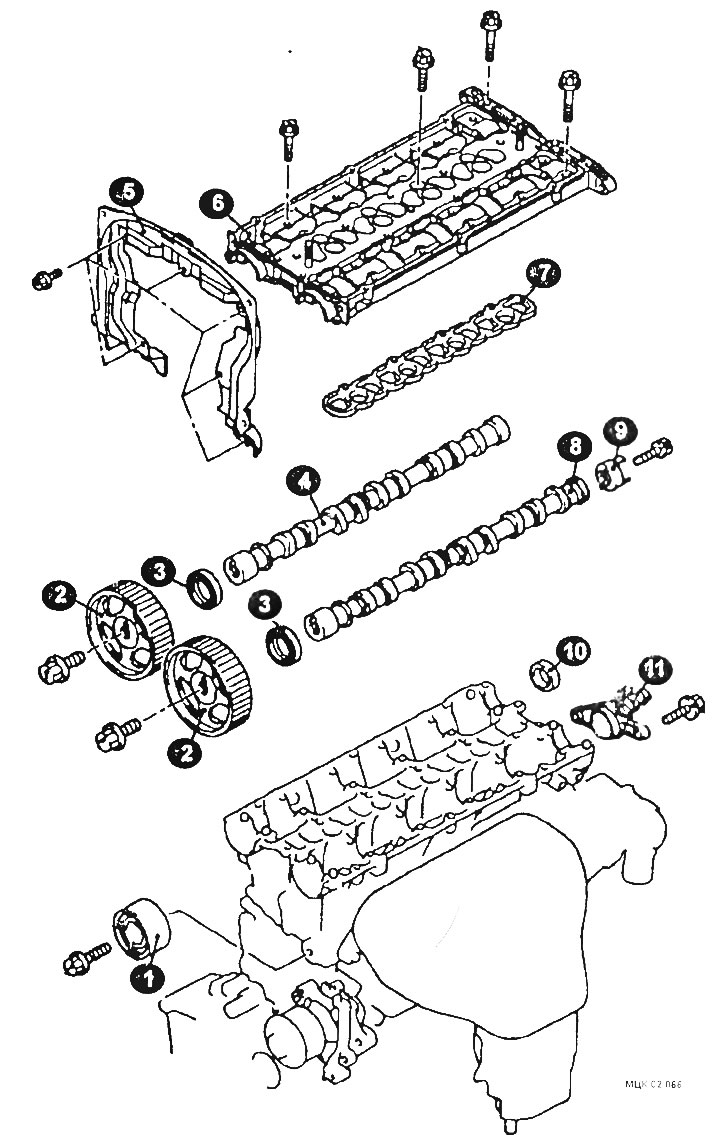

Camshaft fittings

1 - bypass roller; 2 - camshaft gear; 3 - stuffing box; 4 - intake camshaft; 5 - rear casing of the toothed belt; 6 - a cover of bearings of camshafts; 7 - gasket; 8 - exhaust camshaft; 9 - bushing of the camshaft position sensor; 10 - plug; 11 - camshaft position sensor support.

Removing

Disconnect the ground wire from the battery.

Remove the top protective cover.

Drain the coolant from the engine cooling system.

Remove the air inlet hose.

Loosen the screws and remove the engine cover.

Disconnect the crankshaft position sensor connector.

Disconnect the connectors of the fuel pressure sensor, oxygen sensor of the control wiring harness and EGR harness combination, canister purge solenoid valve, throttle position sensor, throttle control servo of the control wiring harness and injector wiring harness combination, ignition coil, ignition system malfunction sensor, camshaft position sensor, coolant temperature sensors.

After undoing the bolts, disconnect the control wiring harness.

Disconnect the exhaust gas recirculation hose.

Disconnect the crankcase ventilation hose.

Remove the ignition coil and intake manifold.

Remove the camshaft drive belt.

Remove the injector harness connector bracket.

Having unscrewed the bolts, remove the cylinder head cover from the intake valves and the gasket.

Remove the cylinder head cover from the exhaust valves and the gasket.

Having fixed the camshaft gear from turning, unscrew the mounting bolt and remove the camshaft gear.

After unscrewing the bolt, remove the bypass roller.

After unscrewing the bolts, remove the rear upper casing of the camshaft drive belt.

Remove the camshaft seal.

Remove the camshaft position sensor support and plug.

Remove the high pressure fuel pump assembly.

Having unscrewed the bolts securing the camshaft cover in several steps, remove the cover.

Remove the camshaft bearing cap gasket.

Remove the camshaft on the intake valve side and the camshaft on the exhaust valve side.

Loosen the bolt and remove the camshaft position sensor bushing.

Installation

Installation is carried out in the reverse order, taking into account the following:

Apply engine oil to all moving parts before installation.

Install the camshafts in the bed of the cylinder head.

CAUTION: Be careful not to mix up the intake and exhaust camshafts. On the camshaft (2) there is a hole on the side of the exhaust valves (1) under the camshaft position sensor bushing bolt.

Rotate the camshafts so that the pins (1) occupied the position shown in the figure.

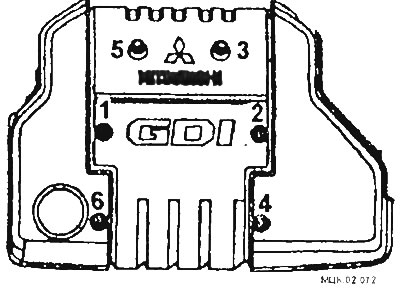

Tighten the camshaft bearing cap bolts to the required tightening torques in the sequence shown in the figure.

Tightening torques:

- Bolts marked in black - 12 Nm.

- Bolts marked in white - 25 Nm.

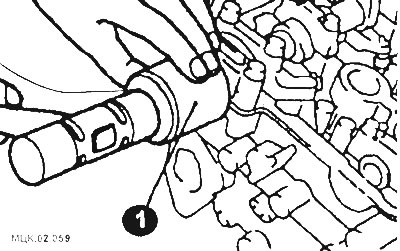

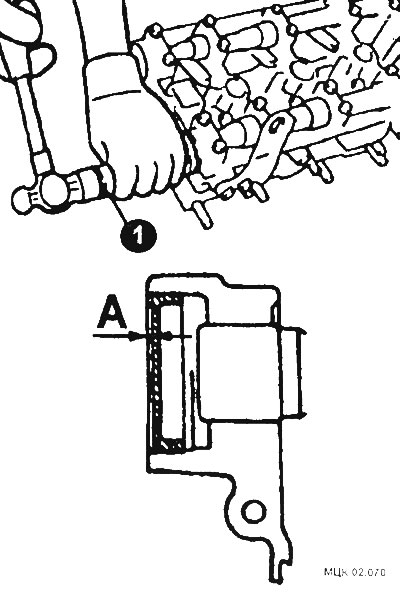

Use the special tool 1 to press in the plug as shown in the figure

Lubricate the inner surface of the seal lip with engine oil.

Using a fixture or a suitable piece of pipe (1) press in the seal as shown in the figure.

Use the same special tool to lock the camshaft pulley in the same manner as when removing and tighten the mounting bolt.

After installing the engine cover, tighten the mounting bolts in the sequence shown in the figure.

After checking for fuel leaks, install the protective cover.

Pour coolant into the engine cooling system.