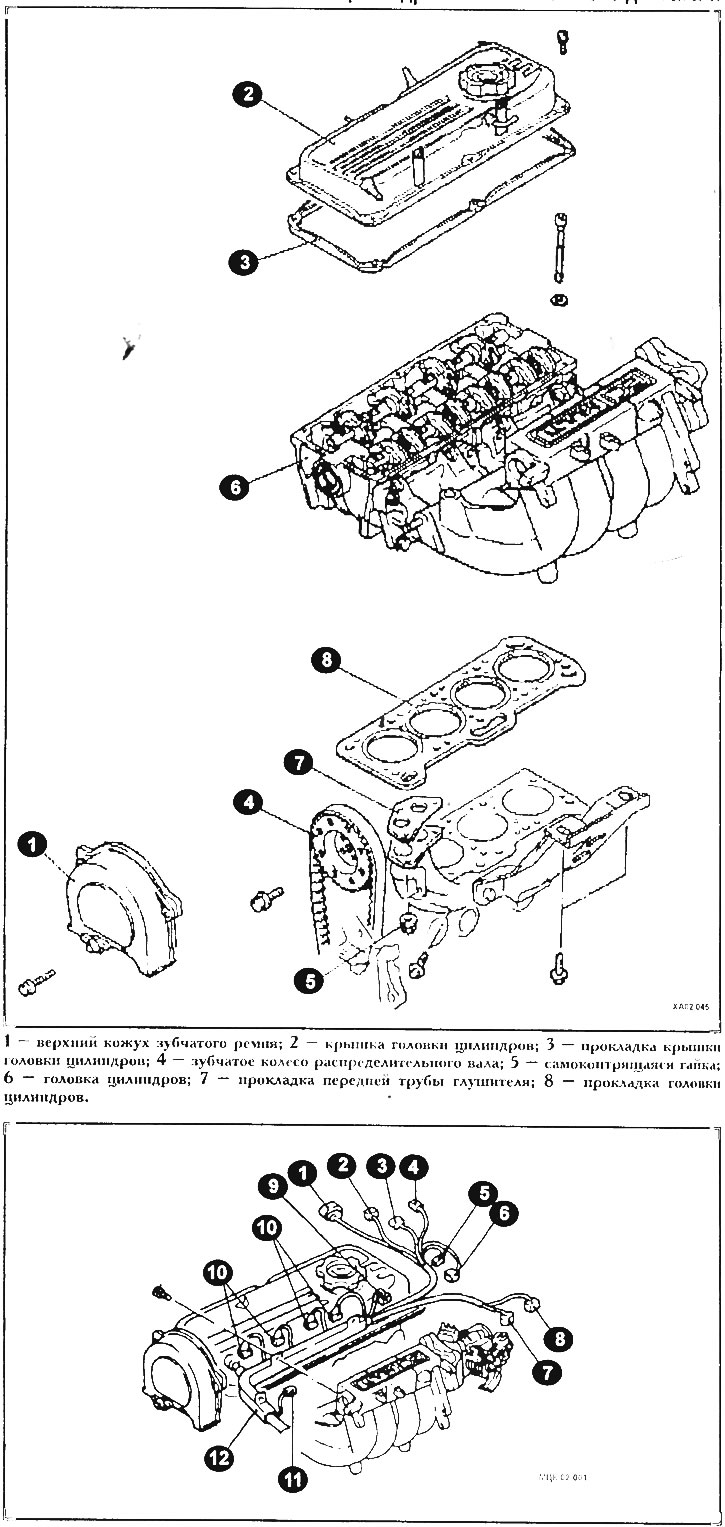

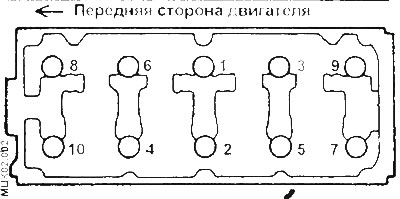

Installation elements of the cylinder head of the 8-valve engine

Remove the cylinder head only when the engine is cold. The intake and exhaust manifolds remain connected.

A cylinder head failure is identified by one or more of the following:

- Low power.

- Coolant leak. Exhaust gases are white when the engine is hot.

- High oil consumption.

- Coolant getting into oil (oil level rises).

- Foam bubbles on the dipstick (liquid oil, gray).

- The presence of engine oil in the coolant.

- Lack of compression in two adjacent cylinders.

- The coolant boils a lot.

Removing

Disconnect the ground wire from the battery. Disconnect the battery with the ignition off, otherwise the control unit of the injection device may fail.

Drain the coolant.

Disconnect the throttle cable.

Remove the crankcase ventilation hose between the cylinder head cover and the thick air intake hose.

Remove the air intake hose between the air filter and thermostat housing.

Disconnect the upper coolant hose from the thermostat housing.

Remove the heater hose from the thermostat housing.

Remove the coolant connecting hose between the throttle valve element and the coolant pipe branch.

Remove the low pressure hose from the suction tube of the hydraulic vacuum brake booster.

Unscrew the subsea fuel line circuit board from the distribution tube. Remove the O-ring. Be sure to relieve pressure.

After releasing the clamps of the clamps, remove the fuel outlet pipe from the pressure regulator. If necessary, fasten the fuel pipes to the body with wire.

Remove all spark plug tips and ignition wires from the distributor cap.

Disconnect all electrical wiring from the cylinder head in the following sequence:

- Distributor connector (1,2) (see fig. MCC02 001)

- lambda probe connector (3)

- Capacitor (4)

- Coolant Temperature Sensor Connector (5) and coolant temperature sensor (6)

- crankshaft position sensor (7)

- IAC connector (8), and then throttle position sensor (9)

- Injection valves (nozzles) (10)

For 84 hp engine additionally:

- knock sensor connector

- Transistor

- Ignition coil and capacitor connector

Remove wiring harness (12) from the intake manifold.

Remove the top timing belt cover.

Remove the cylinder head cover with gasket and fastening clamps on the cylinder head cover.

Set the engine to TDC.

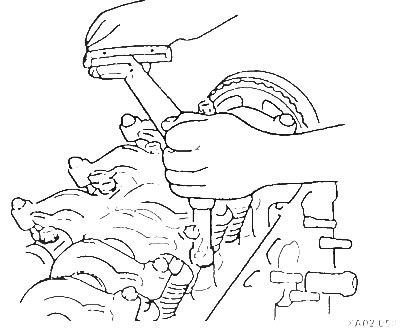

Lock the gear wheel of the first camshaft cylinder with a cable. Loosen the mounting bolt and insert a large screwdriver or rod into the hole in the gear wheel and push against the cylinder head to prevent the camshaft from turning. Place a piece of wood under the screwdriver to prevent damage to the cylinder head. Make sure that the position of the belt on the gear does not change.

Raise the vehicle.

Unscrew the front muffler pipe and secure it to the body with wire.

Lower the car.

Loosen the intake manifold fitting.

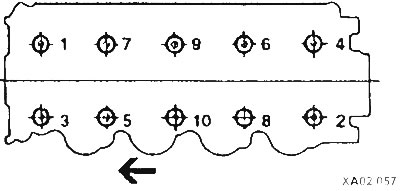

Remove the cylinder head bolts in the order shown in the figure. In this case, first unscrew all the bolts by 1/2 turn, and then turn them out completely.

Check the disconnection of all wires and hoses suitable for the cylinder head.

Raise the cylinder head and place it on two wooden blocks.

Remove the muffler front pipe gasket and cylinder head gasket.

Installation

Before installing the cylinder head, remove any remaining seals from the cylinder head and cylinder block. Cover the holes with a cloth to keep dirt out of the holes in the unit.

Check for oil in the cylinder head bolt holes. If there is, it must be removed by blotting the oil.

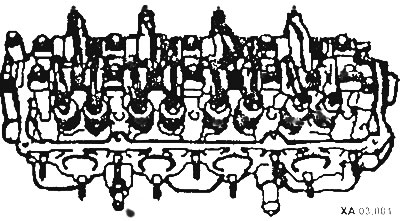

Check with a steel ruler the flatness of the cylinder head and cylinder block, as well as the distortion in various places of the cylinder head.

Replace the cylinder head gasket.

Position the cylinder head gasket without sealant so as not to block the holes. The identification marking must face the cylinder head, upwards.

Place a new gasket on the front muffler pipe.

Install the cylinder head. Make sure that the camshaft is in the TDC position of the 1st cylinder.

Hand-tighten the 10 cylinder head bolts with washers. Replace cylinder head bolts. Tighten the cylinder head bolts on a cold engine in 4 steps. At each reception, tighten the bolts in the order from 1 to 10.

Cylinder Head Bolt Tightening Order

1st reception: with a 20 Nm torque wrench.

2nd reception: with a 40 Nm torque wrench.

3rd reception: with a 60 Nm torque wrench.

4th trick: with a 75 Nm torque wrench.

Install muffler with new nuts.

Put on and fix on a camshaft a gear wheel with a gear belt. Make sure that the camshaft and crankshaft are in the TDC position and the position of the toothed belt on the toothed wheel is not lost.

Install a new cylinder head cover gasket, fit the cylinder head cover and lightly tighten the bolts alternately.

Install the upper toothed belt cover and secure the intake manifold fitting with a force of 25 Nm.

Check the coolant, oil and low pressure hoses for porosity and ruptures.

Put on all low pressure hoses and tighten with clamps.

Attach the cable harness to the intake manifold.

Connect the electrical wiring to the engine.

Moisten all connections with gasoline. Fit and secure the fuel feed pipe with a new O-ring. Be careful not to pinch or damage the O-ring.

Connect the fuel outlet pipe to the distribution pipe and secure with a clamp.

Connect the throttle cable to the throttle body and attach to the intake manifold.

Install the ignition wires.

Put on the low pressure hose of the hydraulic vacuum brake booster and the coolant and heater hoses and secure with clamps.

Connect the air intake hose and secure with a clamp.

Fit the crankcase ventilation hose to the air intake hose and to the cylinder head cover.

Check engine oil level.

Adjust the throttle cable.

Connect ground wire to battery.

Warm up the engine to operating temperature.

Check hose connections for tightness.

Check ignition timing.

Check the engine at idle.

Set the clock.