Alternator V-Belt

Remove the steering servo pump and A/C compressor V-belts, if equipped.

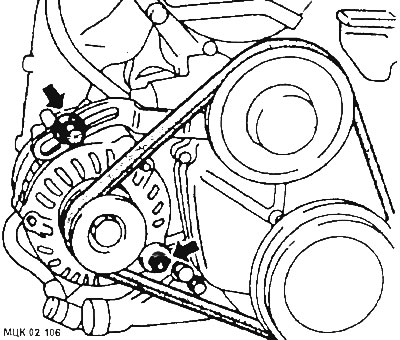

Loosen the alternator nut slightly.

Loosen the tension arm clamp bolt and tilt the alternator towards the engine, releasing the V-belt tension.

Remove the alternator V-belt.

Check the condition of the V-belt, replace with a new one if necessary.

Slide the V-belt over the pulley.

Tilt the alternator away from the engine with a pry bar by tightening the V-belt.

Tighten the clamping bolt and check the tension of the V-belt. The required value is 7.0-10.0 mm.

Install the servo pump and A/C compressor V-belts, if equipped.

V-belt for steering servo pump

Unscrew the mounting and clamping bolts of the steering servo pump and press the pump against the engine. The V-belt will be loose.

Remove the V-belt.

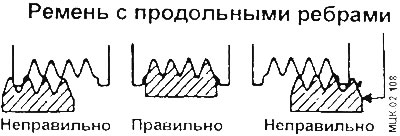

Check the condition of the V-belt, if necessary, take a new one.

Slide the V-belt over the pulleys.

Tilt the servo pump away from the engine by tightening the belt. Check the correct fit of the V-belt on the pulleys and adjust the tension Required value 6.0±9.0 mm.

Tighten the clamping and fixing bolts to 50 Nm.

Check the belt tension again.

A/C Compressor V-Belt

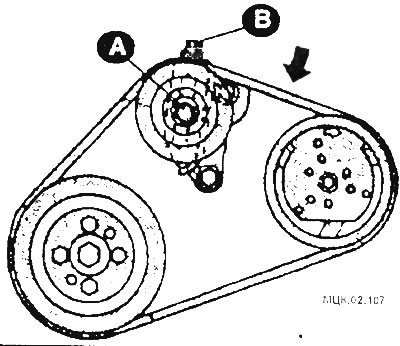

Slightly unscrew the fixing bolt of the tension roller (A).

Loosen the tension of the V-belt by turning the adjusting screw (IN).

Remove the V-belt from the pulleys.

Check the condition of the V-belt, install a new one if necessary.

Install the V-belt in reverse order.

Put on the V-belt and tension it by turning the adjusting bolt.

Check the tension of the V-belt. Required tension values for the V-belt of the air conditioning compressor: new V-belt 6.0-7.0 mm; used V-belt 7.0-8.0 mm.

Tighten the mounting bolt.

Take a test drive and recheck the belt tension.

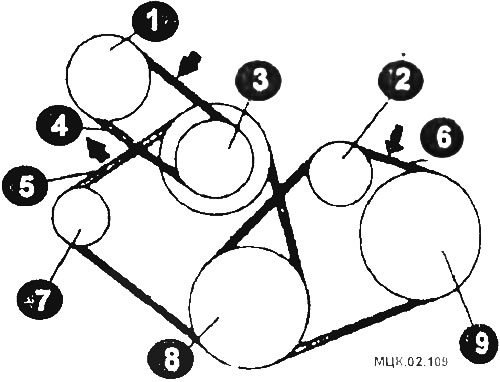

V-belt locations

1 - steering servo pump pulley; 2 - tension roller of the air conditioner belt; 3 - water pump pulley; 4 - V-belt of the steering servo pump; 5 - alternator V-belt; 6 - air conditioning V-belt; 7 - generator pulley; 8 - a pulley with a prick; 9 - air conditioning compressor pulley.

Checking the tension of the V-belts

Check the tension of the V-belt only in the middle between the two pulleys, as shown by the arrow in the figure.

To do this, pull the belt or press the belt with a force of 100 N (10 kg), then measure the resulting belt deflection and compare with the specified value.

If the measured value is higher than the allowable value, the belt tension must be adjusted.

Required deflection values for V-belts alternator belt 7.0-10.0 mm; steering servo pump belt 6.0-9.0 mm; air conditioning compressor belt 6.0-8.0 mm.

The repair of modern engines is not as complicated as it seems and is not very different from the repair of engines of different years of manufacture, as it might seem at first glance. This chapter and the following chapters will guide you through the process successfully.