Check the engine oil level in the engine, add oil if necessary.

- If the amount of oil is insufficient, the oil pick-up may entrain air.

- If there is a lot of oil, the crankshaft agitates the oil in the crankcase, resulting in an oil-air mixture.

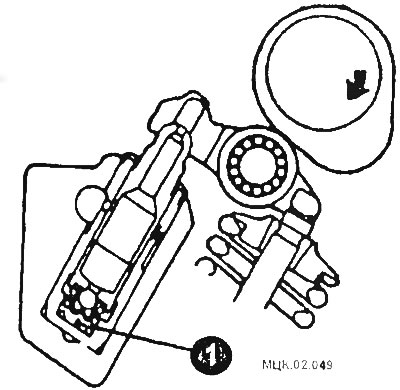

- Air bubbles cannot easily come out of old oil, so the amount of air in the oil increases. Such a mixture, when it enters the high pressure chamber (1) hydraulic pusher is compressed (when pressure is applied to the hydraulic pusher).

The consequence of this is the appearance of sound when the valve is closed. The work of the hydraulic pushers is restored when the air is separated from the oil. Start the engine and accelerate it slowly several times. If the sound disappears, this means that the oil has been freed from air and the normal operation of the hydraulic pushers has been restored.

Gradually increase the engine speed from idle to 3000 rpm, and then gradually decrease the engine speed to idle.

WARNING: If the vehicle has been parked on an incline for a long time or has not been driven, oil may leak from the hydraulic tappet and air will enter the high pressure chamber instead.

If the clicking sound after the described operations does not disappear, check the condition of the hydraulic pushers.

Stop the engine.

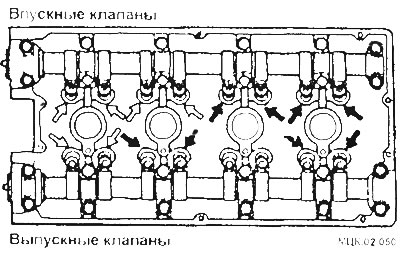

Set the number one piston to TDC on the compression stroke.

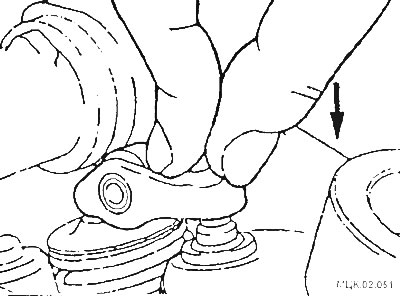

Press the rocker arm in the area marked with white arrows to check the position of the rocker arm.

Rotate the crankshaft 360°clockwise.

Press the rocker arm in the area marked with black arrows to check the position of the rocker arm.

If, when pressed, the rocker arm drops easily when the lobe of the cam is in the closed valve position (see fig.). In this case, it is considered that the hydraulic pusher is faulty and needs to be replaced.

When replacing hydraulic pushers, remove air from them.