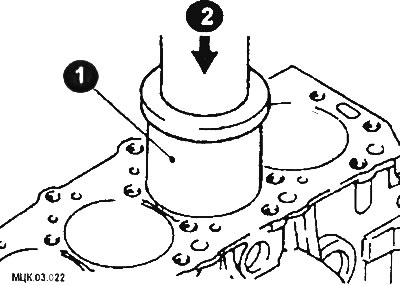

Oil the elements to be installed.

Having correctly oriented the sleeve and after having lived on top of the sleeve the corresponding washer made of soft metal, press the sleeve (1) into the cylinder block using a press (2).

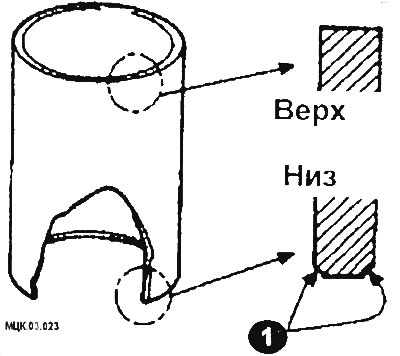

ATTENTION: Remember that the sleeve is installed with risks (1) down.

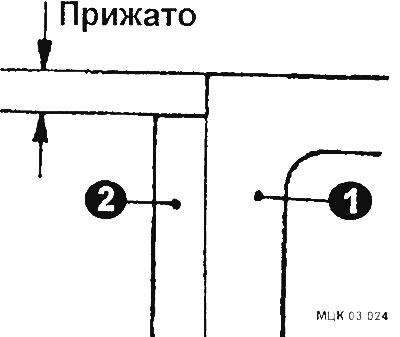

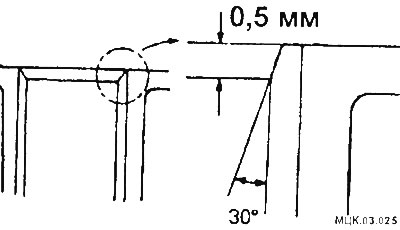

Having processed the upper part of the cylinder block (1) press the sleeve (2). The removed metal layers should not be more than 0.2 mm.

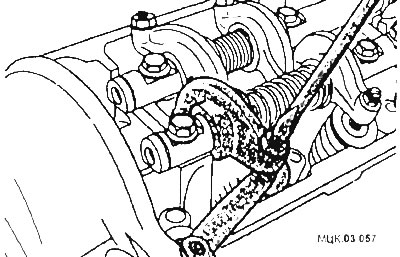

Chamfer the top end of the sleeve.

Check and machine the inner diameter of the liner to the nearest repair size.

After installing the crankshaft, check the protrusion of the piston. If the value is not as specified, replace the pistons and connecting rods.