Start the engine and set the idle speed.

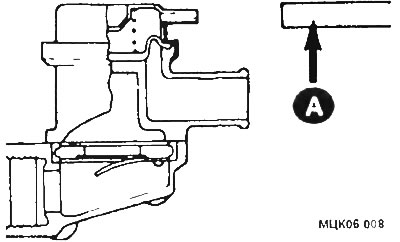

Disconnect the vacuum hose from the second air valve and plug the end of the hose (A).

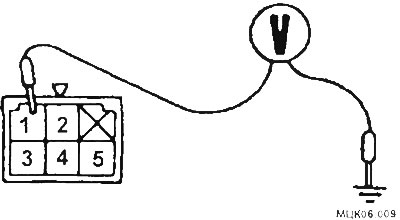

Connect the positive lead of a voltmeter to the negative lead of the feedback solenoid valve.

Connect the negative lead of the voltmeter to ground. In this case, the feedback solenoid valve must be connected.

Let the engine run for 10 seconds at 2000-3000 rpm.

Immediately after reducing the engine speed to normal idle, check the behavior of the voltmeter. If the voltmeter needle oscillates and the center of oscillation is between 2 and 12 volts, the system is working correctly.

If required, adjust the idle speed with the adjusting screw.

If the voltmeter needle does not fluctuate or the center of oscillation is not within 2-12 volts, then check the operation of all mechanical elements of the carburetor and the openings of all jets. Repeat check.

If the system does not work after repairing the carburetor components, replace the carburetor throttle assembly and recheck. If the system still does not work, replace the carburetor.

Connect the vacuum hose to the second air control valve.