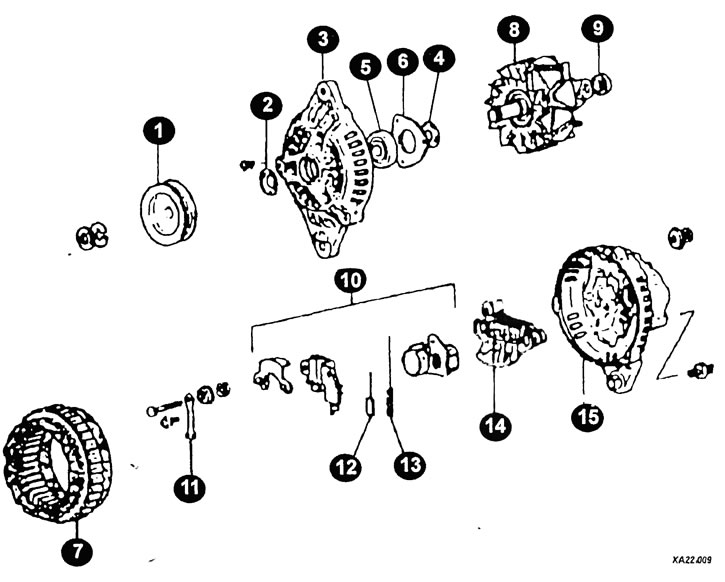

Generator elements of early car models

1 - belt pulley; 2, 4 - stuffing box; 3 - support flange; 5 - bearing from the drive side; 6 - bearing retaining plate; 7 - stator; 8 _ rotor; 9 - rotor bearing; 10 - brush holder / voltage regulator; 11 - connection terminals; 12 - roller brush; 13 - spring; 14 - rectifier; 15 - back cover.

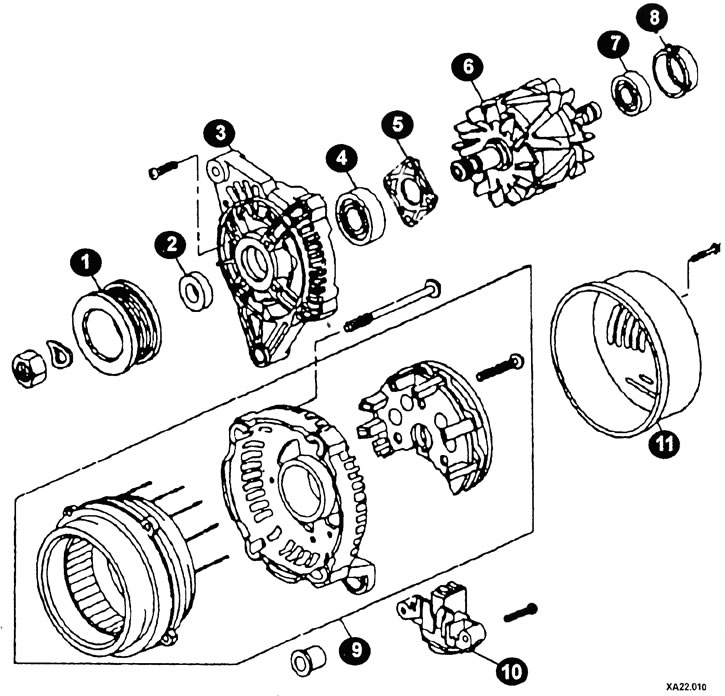

Generator elements of late car models

1 - pulley; 2 - stuffing box; 3 - flange; 4 - bearing; 5 - bearing holder; 6 - stator; 7 - bearing; 8 - bearing cap; 9 - stator with rectifier unit; 10 - brush holder; 11 - back cover of the generator.

Later generator models

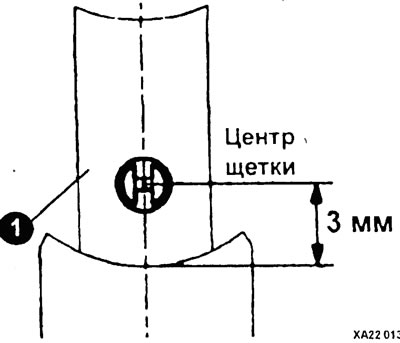

If the brush (1) worn to the center of the mark (3 mm from the middle of the brush holder), replace the brush holder assembly.

Check free rotation of both rotor bearings or replace them. A puller and press tool is required to replace the rear bearing.

Assembly

In early generator models:

- Insert the brushes and springs into the brush holder and solder the leads. Trim the long ends.

- To prevent the solder from penetrating into the brush leads when soldering, hold the brush leads with pliers.

Check the ease of movement of the new brushes in the brush holder.

Place the rear part on the rotor and close. Slide on the front support flange with spacer sleeve and slide on the link sleeve.

Install the fan impeller with pulley and circlip by tightening the nut to 60 Nm.

Insert into the generator housing, bending the ends of the rectifier connection wires so that they do not touch the rotor. Hold the brushes in a compressed position when assembling.

Secure the housing with three through bolts.

Check the ease of rotation of the generator by hand.

Install the generator.

Connect the mass cable to the battery.

If available, set the clock to the time and enter the security code into the radio.