When balancing the wheels directly on the vehicle, do not remove the balancing weights installed during the pre-balancing of the wheels separately from the vehicle. If a balancing weight of more than 28 g is required, it must be evenly distributed between the outer and inner sides of the wheel.

The rotation of the drive wheels is provided manually or by the engine of the car.

Push the wheel by hand so that it slowly rotates counterclockwise. After stopping the wheel, mark the top position of the wheel with chalk.

Push the wheel again, but so that it rotates clockwise. After stopping the wheel, mark with chalk another mark of the top position of the wheel.

WARNING: High wheel positions (easy section) when rotated in opposite directions, they do not coincide.

By dividing the distance between the marks in half, you will determine the lightest part of the wheel. Place one small weight on the rim on either side of this area.

Push the wheel with your hand and spin it again. If, after stopping the wheel, the weights will take the lowest position or will stop anywhere, then this indicates that these weights are enough. If the weights reach the top position, then it follows that their weight is insufficient, and they need to be replaced with weights of a larger weight, after which make sure that the weights stop at the bottom position.

Move the weights selected in this way along the rim at equal distances on both sides of the middle mark and achieve uniform rotation of the wheel in both directions.

Aluminum Wheel Balance Weights

Balancing aluminum wheels requires special weights with nylon coated clamps. The design of these weights is adapted for mounting on the thicker edges of the wheel rim. Fastening of loads is carried out with the help of a plastic hammer.

Installing adhesive balancing weights

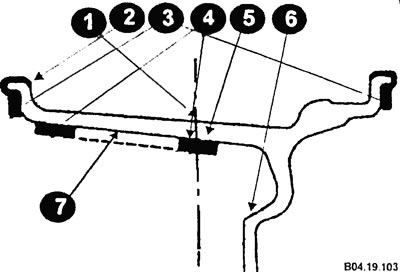

1 - plane of symmetry of the wheel; 2 - inner edge of the rim; 3 - balancing weight with a clamp; 4 - adhesive balancing weight; 5 - adhesive balancing weight (dynamic balancing); 6 - adhesive balancing weight (static balancing); 7 - mounting plane of the wheel.

Clean with a sandpaper the place under the installation of the load to bare metal.

Wipe the mounting location for securing the load with a solution of isopropylene alcohol and water (in a ratio of 1:1). Use a clean cloth or paper towel to wipe.

Dry the prepared area with hot air. The wheel should be warm to the touch.

The adhesive side should be warmed up to room temperature. Remove the protective film from the adhesive side of the load. Do not touch the adhesive.

Put the balancing weight on the prepared place and press it with hand force

Roll the balancing weight with a roller with a force of 70-110 N.