Convergence

Convergence - this is the position of the middle wheels, when the distance between the side surfaces of the tires in front is less than in the back; while reverse convergence occurs when this distance is smaller at the rear than at the front. The purpose of the toe adjustment is to ensure parallel rotation of the wheels.

Wheel alignment is used to compensate for small deviations that may occur in the wheel suspension system when the vehicle is moving forward. The set toe-in angle is a preliminary correction that allows you to get a toe-in value of zero when the vehicle is in motion. Improper adjustment of the forward or reverse toe-in leads to premature tire wear and does not maximize fuel economy. As parts of the steering and suspension systems wear out with increased mileage, additional wheel alignment may need to be adjusted to compensate. When adjusting the wheels, the toe-in should always be adjusted last.

Toe adjustment

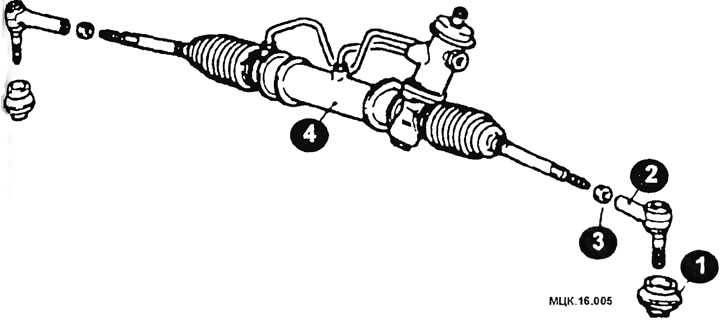

Steering Gear Ends

1 - cover; 2 - tie rod ends; 3 - locknut; 4 - steering gear.

The amount of convergence of the wheels is adjusted by changing the length of the steering rods. Loosen nuts (3) right and left tie rods, then turn the tie rod ends to change the length of the tie rods according to the specification. With this adjustment, the right and left tie rods must be the same length. Required wheel alignment: 0°00'±09'.

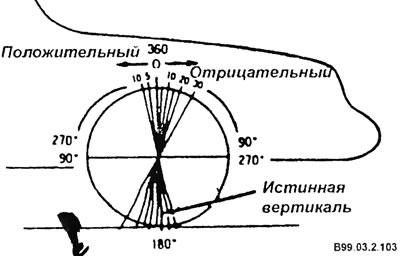

Longitudinal angle of inclination of wheels

Tilt is the deviation forward or backward from a vertical line when viewed from the side of the vehicle. Lean back is called positive (+), forward tilt - negative (-). The tilt of the axis of rotation affects road holding, but does not affect the rate of tire wear. Tilt can be affected by weak springs and vehicle overload.

If one wheel has more positive slope than the other wheel, this will cause that wheel to be «to pull» to the center of the car. As a result, the car will pull towards the wheels with less positive inclination.

The tilt angle of the axis of rotation is measured in degrees and cannot be adjusted. Required value of the longitudinal angle of inclination of the wheels: 2°51'±30' (deviation to the right to the left — 30' max).

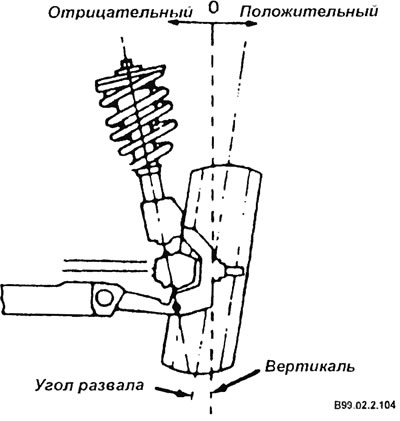

Camber

Camber is the deviation of the top of the tire from the vertical when viewed from the side of the vehicle. When the top of the tire is tilted outward from the vertical, this is called positive camber (+). When the tire is tilted inward, the camber is called negative (-). Camber is measured in degrees from vertical and is characterized by camber angle Camber angle affects both road holding performance and tire wear. If the car has too much positive camber, the outer shoulder of the tire will wear out. Likewise, excessive negative camber will wear the tire's inner shoulder.

Camber is measured in degrees and is not adjustable.

Required camber: 0°00'±30' (deviation right/left — 30' max).

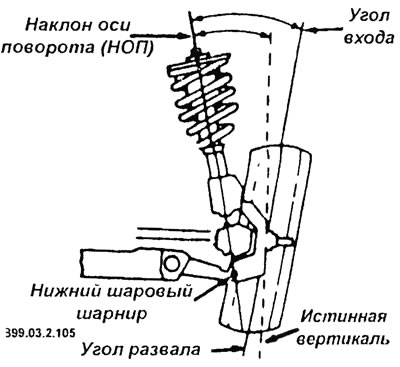

Pivot Tilt

Pivot Tilt (NOP) is a deviation (at the top) knuckle from vertical. The LOS angle is measured between true vertical and a line through the center of the strut and lower ball joint as viewed from the side of the vehicle. Pivot tilt helps the vehicle maintain a straight line and helps return the wheel to the forward straight position. The NOP value for vehicles with front-wheel drive must be negative.

The angle of inclination of the axis of rotation is not adjustable.

The required value of the inclination of the axis of rotation is 12°52'.

Recommendations for checking wheel alignment

Complaints about steering problems and vibration are not always the result of improper wheel alignment. They can also be caused by unbalanced wheels or tires. Another point needs to be checked, the tire may «lead» due to defect or severe wear. «Withdrawal» - this is a deviation from straight-line movement on a flat stretch of road when there is no hand pressure on the steering wheel. For proper wheel alignment, before you start measuring the wheel alignment, you must check:

- air pressure in all tires (must comply with the norm);

- tread wear;

- clearance in the wheel bearings;

- state of ball bearings (lack of backlash in them);

- tie rod ends (eliminate the detected deviations before adjusting the wheel angles);

- beating tires and wheels;

- the condition of the rack and pinion in the steering,

- proper functioning of the racks;

- the condition of the front suspension arms;

- possible excessive loading of the vehicle, if this excessive load is carried by the vehicle, constantly check the installation angles under this load;

- the reliability of the equipment used in checking and setting corners. Strictly follow the equipment manufacturer's instructions;

- regardless of the type of equipment used, the car must be installed on a flat site in longitudinal and transverse terms.

ATTENTION: Satisfactory operation of the car can be achieved in the widest range of adjustment work related to the front suspension.

If you cannot meet the requirements and obtain the design specifications, check the vehicle for faulty suspension components. Make any necessary repairs or replacements. If during the adjustment it was not possible to achieve a convergence value within the established limits, the adjustment should be repeated.

To obtain the correct setting angles for the front wheels, the following conditions must be observed:

- the tread pattern on all tires must be uniform and the tires themselves must be in good condition;

- the air pressure in the tires must be correct;

- all rims must be checked and be in satisfactory condition;

- it is necessary to load each of the front seats with a load of 70 kg;

- the fuel tank must be half full;

- rock the car a few times to stabilize the springs (also stabilize the springs if the car has been lifted before);

- when using installation equipment whose turntable does not fix lateral forces, the vehicle must first be rolled back one meter and then returned to its original position.

The methods for adjusting the wheel angles are different and depend on the equipment used. The instructions provided by the equipment manufacturer must be followed.