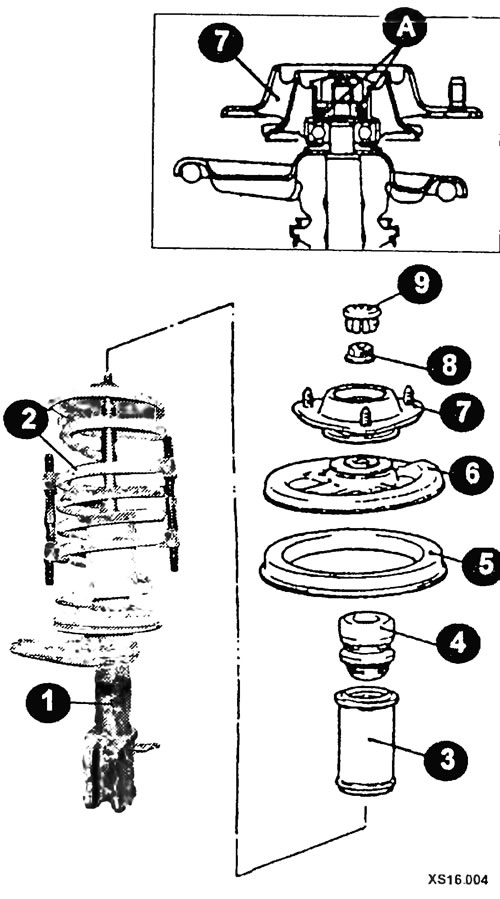

Typical elements of the front suspension strut

1 - stack; 2 - spring; 3 - protective cover; 4 - compression stroke buffer; 5 - spring pad; 6 - upper spring plate; 7 - rack support (chipper); 8 - nut; 9 - cover; A - place of lubrication.

Disassembly

Remove the dust cover.

Install the front stand in a vise.

Using the special tool, compress the spring so that it moves away from the top. When using a spring compressor, make sure that the coils of the spring are securely gripped and that the spring is compressed from opposite sides.

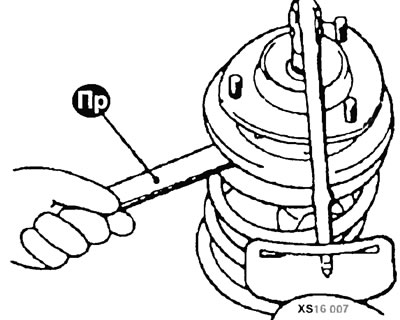

While holding the upper cup of the spring with a special wrench, loosen the nut.

Remove damping strut support.

Remove the top cup and spring pad.

Remove the compression stroke buffer.

Remove the protective cover.

Remove the spring.

Remove the spring compression tool.

Check shock absorber components.

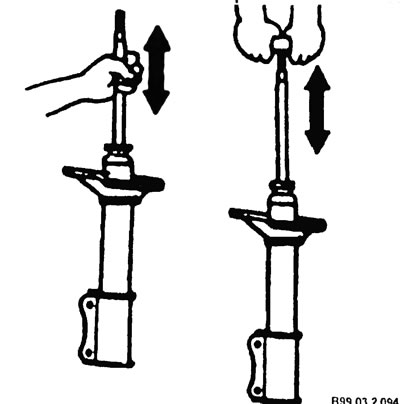

shock absorber

Check the smoothness of the stroke under full compression and extension. Check for oil leaks from the stem seal and welds.

The rod must not have deformation, cracks or other damage. Replace or repair shock absorber if necessary.

Upper rack support

There should be no cracks or other signs of destruction on the rubber elements. The rubber must not flake off.

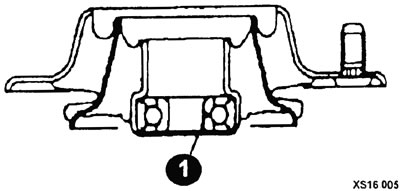

Thrust bearing

When rotating the bearing, there should be no extraneous noise and excessive axial play. Replace bearing if necessary (1).

Helical spring

Check the spring for deformation cracks and other damage. Replace spring if necessary.

WARNING: The springs on the front suspension must be of the same grade.

When installing the spring must be installed as shown in the photo.

Assembly

Assembly is carried out in the reverse order, taking into account the following:

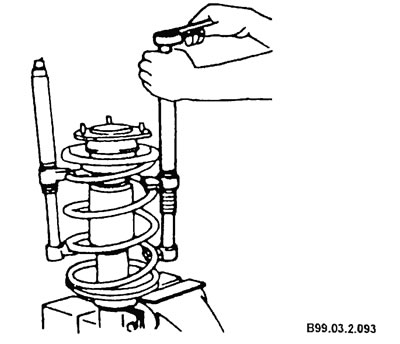

After compressing the coil spring, use the special tool to pre-tighten the self-locking nut.

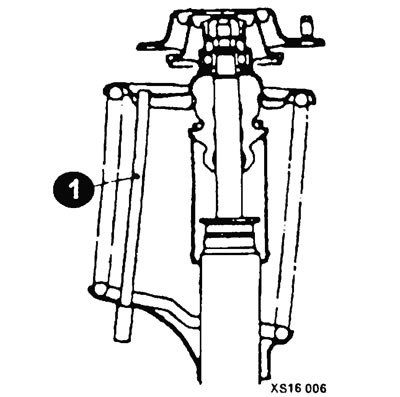

Align the holes in the lower and upper strut spring support cups (some models). This job is easy to do using a piece of pipe (1) as shown in the figure.

Correctly align both end coils of the spring with the grooves in the upper and lower cups, and then loosen the spring compressor.

Tighten the self-locking nut to the required torque using a tool.