Loosen the wheel nuts of the vehicle on the ground.

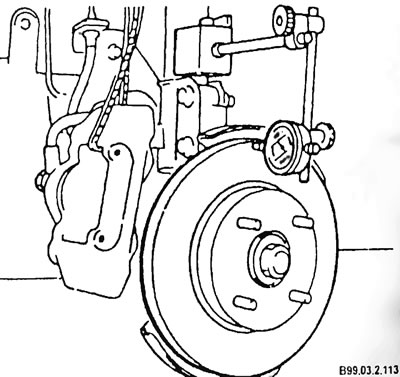

Raise the car and remove the wheel, having previously marked the position of the disk relative to the hub.

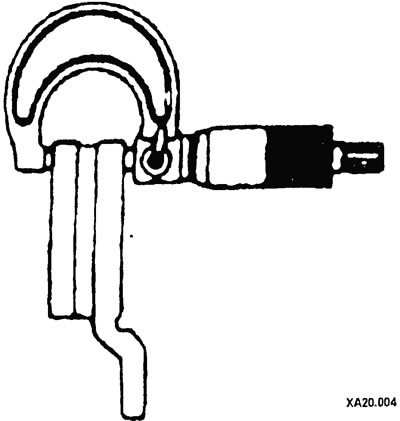

Measure the brake disc thickness. At service stations, special gauges are used for this, because due to wear, an edge is formed on the disc. The brake disc thickness can also be measured with a caliper. However, at the same time, spacers of known thickness must be placed on each side of the disk (e.g. 2 coins). To obtain an accurate result, the total thickness of the gaskets must be subtracted from the measured value.

ATTENTION: Measure at least 8 points along the disc diameter.

When the wear limit is reached, the brake disc must be replaced.

In case of significant cracks or grooves with a depth of more than 0.5 mm, the brake disc must be replaced.

If a dial indicator is available, measure the installed disc lateral runout. Install the appliance as close to the outer edge as possible.

Lateral runout should not exceed 0.15 mm. The cause of a large runout may be a worn front wheel bearing.

Install the wheels, observing the labels applied when removing. Lower the vehicle and cross-tighten the wheel nuts.